SingCore’s patented core material is one of the most environmentally friendly materials on the market, combining state of the art strength and flatness with Earthly friendly materials and manufacturing practices.

Build from Sustainably Harvested Renewable and Recycled Materials

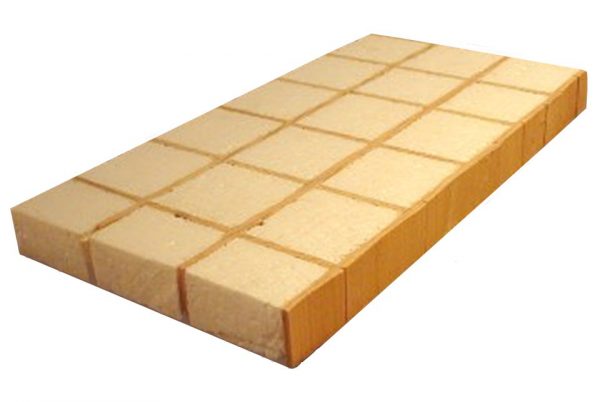

The primary components of SingCore’s system are a wooden vertical grain torsion box infilled with recyclable foam cells. SingCore uses all locally sourced wooden components in the core material. Wood from sustainably managed forests is an eco-friendly resource, with no VOAs, formaldehyde, or other potentially toxic chemical components added.

SingCore uses recyclable EPS foam that includes post-consumer or post-industrial content. The foam components are free of HCFCs, dyes, and formaldehyde and include the following environmental credentials:

- LEED certification credit

- Compliant with the NAHB/ANS National Green Building Standard

- Energy Star approved

- Compliant with ASHRAE standards

- Title 24 (California’s Stringent Standards) compliant

Our patented and patent pending material uses only a fraction of the wood and the total resources of standard wooden construction. This makes our core both light as well as efficient.

Earth Friendly End of Life

At SingCore, we take product end of life seriously, which is why our core is built to impact the Earth in a healthy way.

The main wooden structural components of the core material are all biodegradable materials which form a natural part of the environmental cycle. We abstain from the use of chemical preservatives and other chemical processes which might taint the wood and pollute the environment.

Foam components of the core are 100% recyclable, themselves being made with post-consumer and post-industrial content.

With proper end of life management, SingCore components need not contribute to landfill bloat.

Energy Efficient, Low Green House Gas Producing Production Process

SingCore products are built in the United States using low energy processes. Our highly efficient cold-presses and streamlined hand production methodology ensures that very little electricity or fuel is consumed during manufacturing of SingCore.

Further, SingCore is placed in rainy Washington State, and so has access to clean hydroelectric power. Washington State produces the most green power in the country and accounts for more than 1/4 of all hydro power nationally.

SingCore locally sources the majority of our manufacturing inputs, to reduce overall transportation related greenhouse gas production, and ships directly to your factory or job site using LTL freight to further decrease environmental costs.

Highly Insulated

Because of the foam cell construction of SingCore panels, we are able to boost greater than R-3 / inch of core material, with and optional boost to R-6.5 / inch of core when upgrading to Urethane foam in the core. Combined with our perfect flat construction, which leads to superior weather sealing, our panels are saving energy every day in high efficiency construction projects.

Built for Longevity

The hallmark of SingCore is that we build for longevity. SingCore doors are the only doors on the market that come with a full 50-year structural guarantee.

The hallmark of SingCore is that we build for longevity. SingCore doors are the only doors on the market that come with a full 50-year structural guarantee.

Products with long life spans means there is less overall waste and fewer products making their way in to the waste stream. Our SingCore is made to stand the test of time, and to last a lifetime if not more.