The main challenges of a large door often include warping, very heavy, and poor structural strength.

How do you find the best large or oversized door?

Guarantee the weight. How many pound per square foot? (lbs./ft.²)

Find a structural guarantee. It is easy to lightweight doors, but it is much more challenging to build a lightweight door with high strength.

Last, most importantly, is how flat the door is.  Doors that are very tall, wide, and thin are the most difficult to build perfectly flat. Every door is different and has to be treated individually. Sing Core has patented and patent-pending technology to keep the door, no matter the size, flat and compliant with AWI standards.

Doors that are very tall, wide, and thin are the most difficult to build perfectly flat. Every door is different and has to be treated individually. Sing Core has patented and patent-pending technology to keep the door, no matter the size, flat and compliant with AWI standards.

High precision is not only visually appealing, but is most important for structural integrity. High precision is crucial for properly bonding adhesion which is a major factor for the door’s structural strength. Sing Core has the highest precision in the industry, maintaining a tolerance of ± 0.007”. Check the precision of other door cores before you buy honeycomb core.

This is why our core is guaranteed much longer than other cores.

What is a large or oversized door?

A door that measures more than 48” wide or 96” tall.

Although Sing Core makes doors of any size and many are extremely large, oversized doors, there are several size plateaus that affect pricing tiers of the Sing Doors you may desire.

Another challenge faced with high end large door is to make the faces seamless.

This can be quite costly.

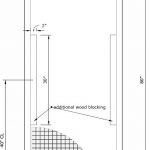

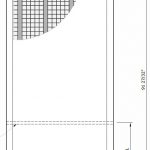

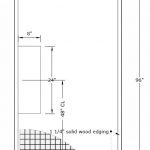

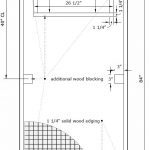

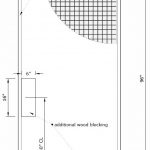

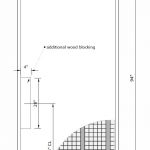

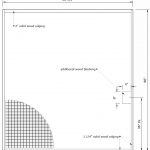

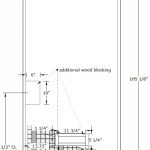

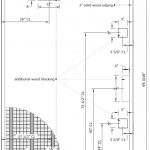

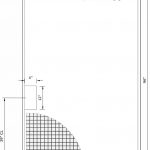

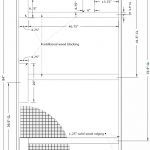

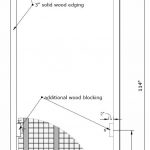

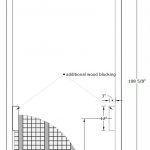

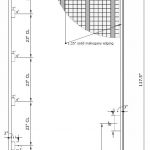

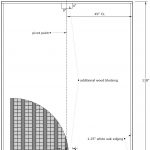

But if large doors are built in sections and joined together on-site by the installer, you can save on shipping and handling costs, especially if the large door needs to fit in an elevator or tight doorway. Sing Core has built many large doors that are joined on-site without any warping. Average dowels and even larger biscuit will not prevent door warping. If you join several 5’ x 10’ x 2” doors together, it will not be an easy task. But Sing Core has had many years of experience with over sized doors, devoted to solving the common issues with larger doors while providing the most current patented and patent-pending technology.

Otherwise, modular door sections joined on-site will be the best option. There are two major factors to achieve high quality when building large doors. One is to make sure there is no warping once the modular sections have been joined. The second issue is maintaining a high precision joint line so that it is not noticeable. This requires a very high precision core to achieve. Sing Core is the most precision door core available, with a tolerance of ± 0.007”. It is important to be sure that the thickness of the core is within these tolerances. We suggest that you check the door core precision, especially when it is a honeycomb core.

Strength plays a key factor when building larger doors. Larger doors require extra strength to maintain a long life span. It is important to learn what the core structure is made of. Doors are not the same as walls. Doors need to move repeatedly everyday while walls are permanently placed. Walls commonly use 2” x 4” framing methods which do not work well for building doors. If the structure of the door is not strong, it will feel like a solid door. When you close the door, there will be a rattling sounds or it can deform over time. It is very easy to tell, all you have to do is close the door and hear how strong or solid the door is made.

What type of skin is best to build a large modular door?

Paint Grade

It is easy to hide the seams. Seams can be almost unnoticeable if modular sections are joined with a Sing Spline. If the spline is made of solid wood, it can move or warp after the moisture levels change and it will be reflected on the surface of the door. This can cause the surface of the door to crack after the seasons change.

HPL is available in a wide variety of patterns. The best choice for HPL is a vertical pattern to help the joint blend into the surface. The photo on the right demonstrates the precision of our modular oversized door joining method. The sections are being held together by a Sing Spline only. Click here to see our Sing Spline

Metal doors are traditionally very heavy, but with Sing Core inside your metal door can weight roughly 1/3 of a traditional metal door. You can choose from any type of metal you would like, but our most commonly made metal doors are Aluminum or Cold-Rolled Steel. If it is paint grade metal, the seam can be filled with joint compound and then painted making a seamless joint. Click here to see a paint grade Sing metal door.

Fiberglass

Fiberglass can be a smooth surface or have textured pebble skin. After priming and painting, the seam will be invisible. Our most popular skins are fiberglass and HPL due to their light weight and are very easy to join on-site.

Wood Staves

Wood staves are much thicker than veneer, meaning that they have additional strength. It is easier to hide the seam with the staves laid horizontally instead of vertically. See the Kyoto code.Wood staves have the advantage of being easily repaired. It is more stable and looks better than rare solid wood. The thinner the wood, the more vulnerable it is to cracking. We highly recommend 1/8” or thicker wood staves.

Wood Veneer

Wood veneer is often much more challenging because it is usually very thin, normally only 0.020” thick. We always suggest using thicker wood staves which are usually 0.125” thick rather than veneer. Sing Core has built hot pressed wood veneer door panels as large as 12’ x 10’. It is very costly to use veneer, oftentimes we use wood staves to build larger doors. However, you may need wood veneer to match the surrounding wall, certain design pattern, or for book-matching properly.

|

|

|

|

Standard Sized Doors

Standard sized doors include any standard sized door that you might purchase over-the-counter, such as the most popular sizes:

| Door Height | Door Width |

| 6′ 6″ | 2′ 0″ |

| 2′ 4″ | |

| 6′ 8″ | 2′ 8″ |

| 2′ 10″ | |

| 7′ 0″ | 3′ 0″ |

| 3′ 6″ | |

| 8′ 0″ | 4′ 0″ |

When a door measurement, exceeds either 8 ft. tall or 4 ft. wide, oversize pricing applies such as

Single Oversize

Oversized pricing is based on 4×8 increments. So a “Single Oversized” door could exceed either 8 feet tall or 4 feet wide, but not both.

Double Oversize

Double oversized refers to doors that are both over 8 ft. tall and 4 ft. wide.

Triple Oversize

Triple Oversize refers to large doors that exceed 8 ft. in both directions length (height) and width.