Sing Sandwich Core (lightweight panel, sandwich panel, honeycomb panel)

1. What is Sing Sandwich Core?

The revolution or evolution of wood working, metal fabrication, plastic and cement meets the invention of patented Sing Sandwich Core (see the many uses of Sing Core). Sing Sandwich Panel provides the wood worker with pre-built torsion box at an affordable price.

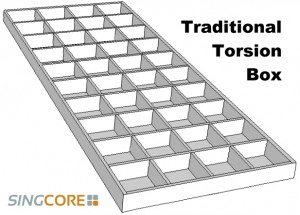

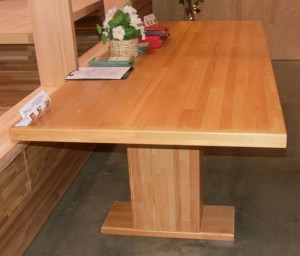

Traditional torsion box (above) which could take all day to build

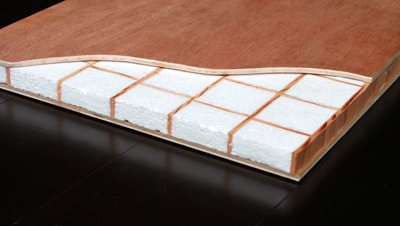

or insulated pre-built Sing Sandwich (reinforced torsion box see below)

2. Why Torsion Box?

Because other methods of building a table top are basically inefficient. For instance, a table top built of a solid material will shift and move over time compromising its degree of flatness. Also solid materials that are less likely to move are extremely expensive, heavy and would only be considered for a permanent fixture.

The torsion box table top design gives as flat a surface area as possible while reducing the weight of the table top due to the hollow areas in the center of the boxes. Using a torsion box design, a craftsman can build the most flat surface using 1/10th the solid material.

3. How does Sing Sandwich Core work?

aka: lightweight panel, sandwich panel, honeycomb panel

Examine the theory behind the torsion box/sandwich panel/lightweight panel/honeycomb panel

please click link below:

Use Sing Sandwich Core’s torsion box to replace conventional wood core, particle board core for the true flat, light weight and high strength characteristics.

There are several core materials also widely used to function as torsion box such as:

| * Wood core * Furniture wood core * Table wood core * Solid wood core * Wood core table * Wood core furniture * Wood door core |

Google Search: wood core

Why do craftsmen use wood core? Because it reduces the cost of exotic woods and by alternating grain orientation – like plywood – it can help to minimize warping; but even plywood warps and is very heavy. Using lightweight Sing Sandwich Core may eliminate warping altogether.

| * Sing Sandwich Core is 10% of the weight of solid wood based core. * Sing Sandwich Core is stronger than steel lbs for lbs. * Sing Sandwich Core is safe to work with fewer injuries if the object is a large door table or large piece of furniture. |

Get your torsion box pre-built for you in 2 ft. x 4 ft. Sing Sandwich Core sections.

Imagine being able to build a torsion box work table and hundreds of lightweight, high-strength true flat, non-warping panels – endless applications – without the time, energy and cost of building the torsion box yourself?

4. How to work with Sing Sandwich Core

4. How to work with Sing Sandwich Core

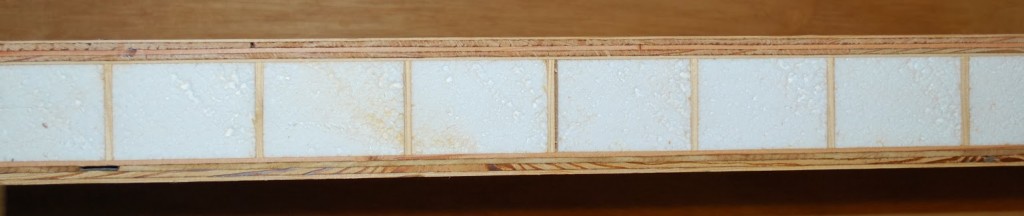

Just use your normal wood working tools and treat it just like you would solid wood core, particle board core (substrate) or any other core materials (lightweight core, sandwich core, honeycomb core). The best core (click here to see charts to compare) material at an affordable price.

Patented Sing Core supplies the military, high-end millworks, general contractors and architects across the USA (see clients list) with massive torsion box structural panels that are lightweight, stronger than steel pound for pound and perfect true flat –> click here <– to see professional Sing Panel for large door applications guaranteed to be true flat and stay flat for 50 years.

Solid wood and metal will move and adapt to temperature compromising the functionality and seal of the most elegant hand-crafted wood door. Diligent woodworkers have sought out Sing’s solution to the oversized wood door.

The same scientific solution of reinforced torsion box applies to tables and other structures that can be built without traditional wood framing for furniture or stick-built homes.

5. How to build with Sing Sandwich Core

It’s easy to build your own products on demand, as you need it in any size you want.

It’s easy to build your own products on demand, as you need it in any size you want.

This is the most popular in-house Sing technology used by craftsmen and millworks.

You might have never known how easy it is to build using this cold-press drop-in method.

How Easy Is It?

This is how simple it is to for you to use our Sing Sandwich Core (pre-built insulated and reinforced torsion box).

All you have to do is to coat the underside of your bottom skin with regular carpenter glue…

Place your wood edges atop the glued-side of the skin…

Then fill the void with pre-built torsion box pieces until full.

Place glued top skin onto your completed work…

Finally cold-press until dry (those two pc of panels to hold the gluing object are made of Sing panels).

This simple cold press (above) is made of two pieces of Sing Panel (one on the top and one on the bottom) and clamped together with pipe clamps.

It’s that easy: Congratulations; you just made your own insulated reinforced torsion box panel!

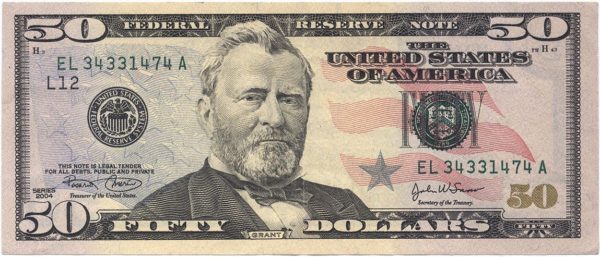

6. $50 to Share Your Sing Project with Sing Core

Submit a copy of your receipt along with drawings and photos of your project built with Sing Sandwich. You will receive a $50 cash reward for sharing your project and helping to make the world a better place. You will also receive a certificate recognizing and honoring your sustainable efforts.

Submit a copy of your receipt along with drawings and photos of your project built with Sing Sandwich. You will receive a $50 cash reward for sharing your project and helping to make the world a better place. You will also receive a certificate recognizing and honoring your sustainable efforts.

Thanks for a Better World

It’s our way of saying thanks for helping us make a sustainable planet for all creatures using patented Sing Sandwich panels.

Details, photos and instructions compliments of Lightweight University.