Here are the top 4 ways architects are making the world’s best doors with Sing Core inside.

1. Check the Size

Even the biggest doors, can save the budget and increase performance by making minor adjustments in the size. How tall? How wide?

2. Check the Thickness

How thick is your door? Increase a 1.5-inch door to 3 inches and enjoy 4-times the strength with a weight increase of as little as 5 to 10 percent. A little thickness can go a long way.

3. Check the Skin

Some door skin material is more accommodating than others, different wood species have varying degrees of challenges

Veneer. Very thin veneers are best laid on a very smooth layer of MDF for flawless hot pressing. You will find Sing Core inside the best high-end veneer doors.

Wood Stave: Wood stave skin is sliced and sanded from larger wood stock. We suggest 1/8th inch or 1/4 inch if cutting designs or grooves into the surface.

Paint Grade. MDF is again, an amazingly smooth surface to paint upon for outstanding paint grade doors.

Covered Plywood. Plywood can be covered in a wide variety of skins, such as fiberglass, vinyl, HPL, Formica, ceramic, or metals, such as aluminum, or steel.

See: Other Door Skin Types

4. Check the Sing Core Inside

Sing Core is not just one patented product, though it did start that way. The sing Core door solution now includes many different patents and patent-pending techniques that help to solve the problems facing architectural doors of any size or style, from door blanks to stile and rail doors. By making slight adjustments in the door’s measurements or other ingredients, you could reduce the cost of mandatory engineering and technology to keep the door straight, thereby reducing the overall cost of the door. This is the specialty of Sing’s True Flat Team.

How Are Architects Designing the Best Doors in the World?

Architects are the most discerning creators in the world because they desire to push the design envelope to the next level? One of the most dramatic impacts they can make on a new design is to apply their imagination to the structure’s first impression.

The project budget may not allow for a structural design that is so unique that anyone who approaches the project knows they are encountering a unique structure and experience based on the style of the structure. The next point of impact is the front door.

Sing Core empowers architects to create these one-of-a-kind creations that serve as the main entrance to the structure that represents their efforts to share their creativity and imagination with the world. See these Impossible Doors.

How to Design the Best Door in the World

Size Makes a Difference

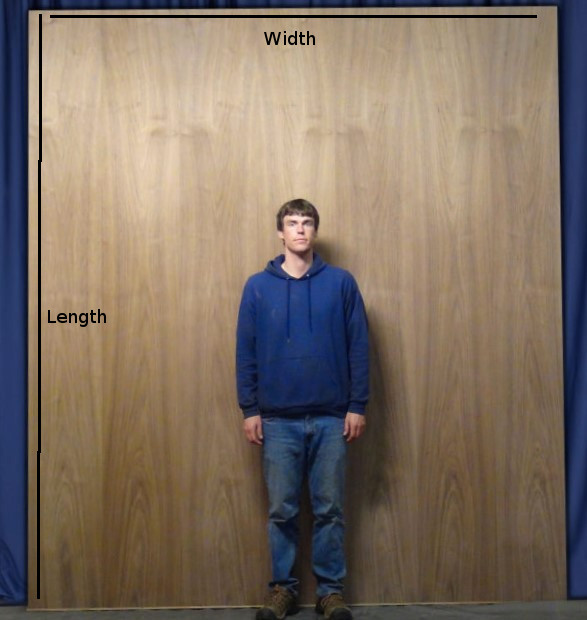

| A common approach to an architectural front door is to create a door of immense size. Architects understand that there will be issues with incorporating a huge front door. The first challenge they face is balancing issues associated with weight and strength. |  |

Door Weight

Big doors are heavy. The bigger the door, the heavier the door. Big doors can be dangerous to install and can be dangerous to use. Large oversized heavy doors are expensive to make, handle, ship, install and maintain over time. Note: Door hardware is based on the weight of the door, a very heavy door, will require very heavy duty and expensive door hardware. (In some cases just the hardware will cost more than the door.)

Door Strength

At some point, as the door size increases, strength and dimensional stability decline. A very large door presents many challenges with trying to keep the door straight and true, so that it not only looks good but operates flawlessly over time.

Door Skin Makes a Difference

The exterior surface of the best architectural doors in the world presents their own set of challenges, whether they be exotic wood (natural wood grain, while it is beautiful, poses the most problem for potential movement due to the nature of the wood’s grain), hot rolled steel, or any other type of surface material.

| Veneer

High precision veneering requires the smoothest surface for hot pressing, so we use our lightweight MDF which also has excellent adhesion. Thin veneers (like .030) can be very fragile and are susceptible to damage easily, so for high traffic doors, we suggest upgrading wood stave for strength and longevity.  Wood stave is sliced and sanded from larger wood stock. We suggest 1/8th inch (1/8 inch compared to ¼ inch looks identical but less chance to move) or 1/4 inch if cutting designs or grooves into the surface. It can be challenging depending on the wood species and may require more Sing technology inside to keep warp-free.  MDF is again, an amazingly smooth surface to paint upon. Assure your paint-grade doors are beautiful as you are coating them with high-precision finishing paint.  Plywood can be covered in a wide variety of skins, such as fiberglass, vinyl, HPL, Formica, ceramic, or metals, such as aluminum, or steel.  |

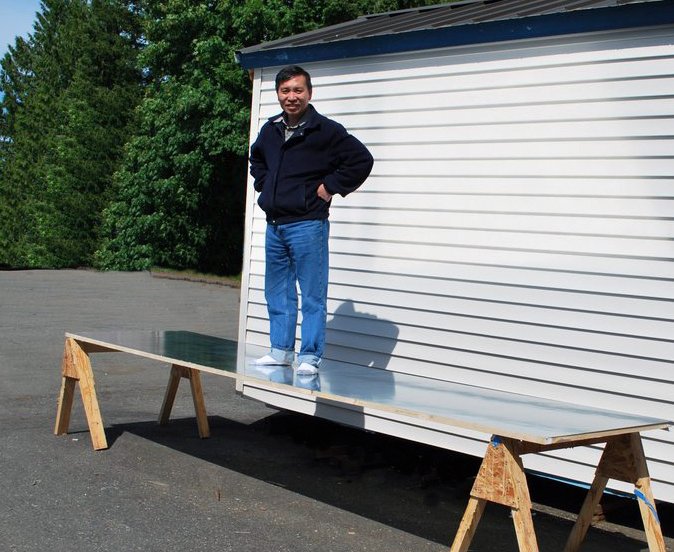

Door Thickness Makes a Difference

Managing a very thick moving door can present challenges, even more so if the door is very thin, and requires a great deal of engineering to make it stay straight and true over time.

Exterior Doors

Exterior doors are by far the most impressive and challenging architectural doors to consider, because they are used regularly, and one side of the door is exposed to opposing environmental conditions, increasing the door’s inclination to favor one side over the other, resulting in a warping condition.

Extra patented and patent-pending Sing technology is necessary to counteract these conditions, and therefore Sing’s True Flat Team must be aware of the conditions this door may be exposed to in order to have the necessary anti-warp technologies inside prior to manufacture or installation,

High Precision

When it comes to high precision, no other door substrate can compare to Sing Core. Go ahead and pull out your micrometer and measure for yourself. Sing Core sports the highest tolerances at +/- .006-in. If your job demands high precision, it doesn’t get any better than Sing Core.

Perfectly Straight

In the world, as we know it, there is no such thing as perfectly straight. The AWI does advise that there are tolerances allowed for straight non-warped doors, and the hardware manufacturers create mounting and articulating equipment to accommodate these specifications.

But this one thing we guarantee, that your door with Sing Core inside will be the closest thing to perfectly straight possible, and it will perform better than any AWI standard.

50-Year Guarantee

Your door, with Sing Core inside, can be guaranteed not to warp, bend, twist, cup, delaminate, otherwise fail for 50 years. No other door in the world can offer The Only 50 Year Non-warp and Structure Guarantee as Sing Core can.

Maybe you will agree with our clients who say,

“Sing Core is The Only Way to Build High End Large Doors.”