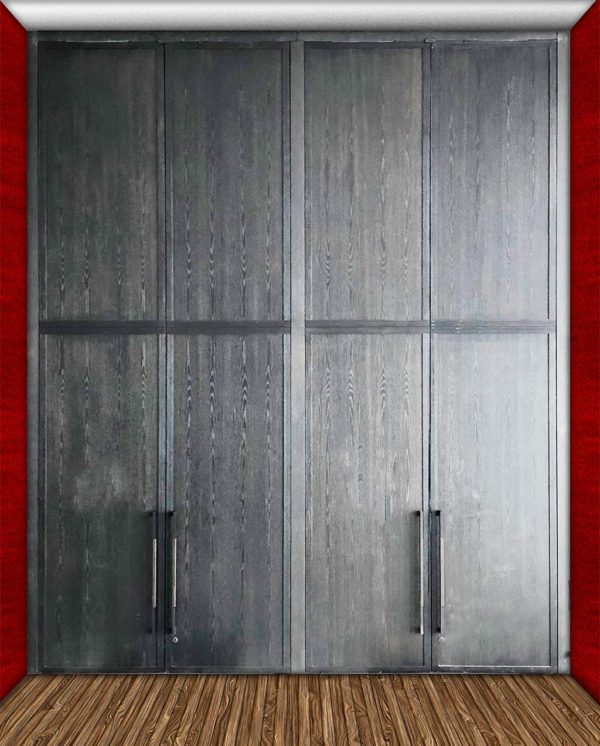

The top doors in America are installed in the top floor of the tallest building in the United States, located at One World Trade Center, New York. These 16 ft tall 3 ft wide 2.25-inch thick warp-free wood veneer doors are among the only Eco-friendly lightweight, high strength, insulated doors made in the USA that can be guaranteed not to warp, bend, twist, cup or otherwise fail for 50 years.

If you’re one of the top contractors in America, when you’re called on to deliver the best tall doors to the top of the World Trade Center, you want to make sure you’re not embarrassed when your sleek white oak doors fail due to warping. See: How to Make the Best High-end Veneer Doors.

These 16 ft. tall doors feature 0.020 veneer very long and matched perfectly.

Underlayment

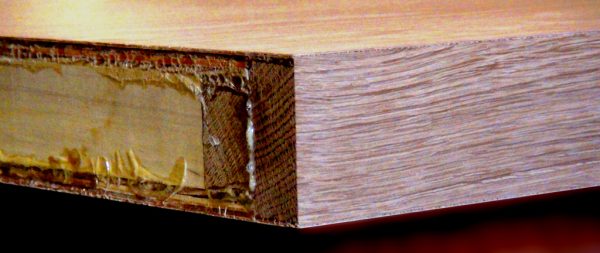

The secret to creating an incredibly smooth wood veneer door is what lays underneath the natural wood veneer. At Sing Core, the True Flat Team is likely to laminate 0.020 veneer over top of 1/8″ MDF on top of 1/4″ plywood. Of course, your door will only remain straight for 50+ years if you have Sing Core technology inside.

|

|

|

Professional

When your reputation depends on it, you need the backing of a professional company that can deliver the goods and have your back, and there’s only one company in the United States that builds large doors which can be guaranteed for 50 years.

The most exclusive architects in the world specify “Sing Core inside” their doors when nothing less than the very best will do, and you want your customer to be on the top of the world.

|

What makes a hot-pressed panel worth so much more with Sing Core inside?

Architects are increasingly specifying their large high-end hot pressed veneer panelized walls, features, and doors have Sing Core inside (accounting for about one-third of all our products which are sent to the greater New York-area). The contractors generally contact Sing Core directly first, due to being specified. Though Sing Core does not actually do the veneering. Sing Core provides the high precision substrate that is shipped 3,000 miles from the manufacturing location in Washington State, to the high end millwork in New York (or wherever the nearest hot press specialist is near the construction site) to do the veneering there. We Do Not Veneer

We always recommend using your local veneering professionals for custom veneer doors. We do not provide veneer or install it. It is our policy to subcontract veneering jobs to the best veneering professionals in the USA.

If you offer hot-pressed veneer services or cold-press veneering to your clientele, your highest paying customers will gladly pay you more if your panels have Sing Core inside.

|

|

|

Hot-pressers Are More Successful and Profitable with Sing Core.

For years, Sing Core has been providing high-end local and nationwide hot press veneer professionals with premium core material that eliminates the need for crossbanding.

Let’s face it, nothing can compete with the beauty and elegance of a perfectly hot-pressed panel, and for that sweet-spot in the marketplace, those clients that demand the best and are willing to pay for it. The manufacturers and millworks that have Sing Core inside their hot-pressed products are making bank by specializing in these ultra-high-end projects.

If you are a veneering professional, then we would like to work with you! Please contact us, we have plenty of veneering jobs to subcontract out.

For standard sized doors, we send our premium substrate to veneering professionals near the job site to be hot-pressed. If the doors are very large, we may have the veneering professionals prepare the veneer for us to cold-press in our facility.

Let’s take a tour of these revolutionary doors from the factory to the top floor of World Trade Center One…

- Shop Drawing

Photos taken from the edge of the panel show the perfectly straight quality. The panel shows glue on the edge, because the customer requested untrimmed ends.

- Perfect Sides

- Highest Quality True Flat

- Perfect Oak Edges

Measuring at 2.25 inches thick, this is the most premium quality door money can buy. Due to the patented and patent pending SingCore technology, this 15.5 foot long, 3 foot wide, 2.25 inch thick pivot door is straight as an arrow, better than AWI standards.

Many Ways to Build It

Depending on your budget, you have a number of different options when you opt to go with Sing Core.

- You can order substrate only and apply your own soft wood or hard wood veneer (economy option)*

- You can order substrate only and have your local veneering professional apply your veneer of choice (recommended option)*

- You can choose solid wood edge banding

- You can choose a hardwood frame

How to Build the Perfect 16 ft. x 3 ft. High Precision Warp-free White Oak Door

You start with patented and patent-pending Sing Core inside sandwiched between American-made A/B plywood with solid oak around all four edges.

After pressing, trim the edges, then add another 1” x 2.25” solid oak to the edges. Sand it to perfection then hot-press 16th-inch white oak veneer, then all you can see is solid white oak. Beautiful.

The result is a perfectly flat lightweight white oak door that is stronger than steel pound-for-pound, weighing in at a mere 220 lbs.

* Professional veneering can be very tricky. If you are getting substrate from Sing Core and having your millwork (or someone else) apply the veneer, be certain to affirm that they have the expertise to apply the veneer appropriately. We use the best of veneering professional in Washington state. We can guarantee our veneering, if you have veneering done off-site, it is their responsibility to do it correctly. A faulty veneer could jeopardize your Sing warranty.

Ask us if you have any questions.

- White Oak

Full Service Veneering:

We offer our ultra high quality veneering service for customers who need that extra level of quality.

The process of applying veneer isn’t simple. One wrong move can ruin your product, which means large amounts of money fixing the problems. It can even result in the need to buy new doors. We have solved all of these problems for you, but your choice of methods will ultimately depend on your budget.

- Exotic Teak Veneer Skin

If you decide to veneer your own doors, we offer more than one option:

Premium Option

MDF layer. We apply an MDF layer to our legendary ply substrate. This offers you the most stable option for applying your veneer job. You can save money on your end by getting the job done correctly the first time. Besides, if you do not apply your veneer to the proper surface, it could result in having to redo your veneer job. In the worst case scenario, applying your veneer improperly can ruin the doors. That’s why, with our premium option, we ensure you a proper surface for your application.

Standard

Our standard substrate, made from high quality plywood, offers you a great surface to apply your skins, but you must make sure to do your veneer job properly, or it could result in a ruined veneer job. Veneering requires experts who have a very high level of skill.

- Hard Maple

- Amazing Sapele and Oak Stave Combo

Note: Sing Core is not responsible for any damages which result from skins improperly applied by our customers.

Other Skin Options:

In our economy class products, we offer soft wood and hard wood plywood skins. We also offer MDO, MDF, Formica, Masonite, and many other skins. Click here for more information.

In our highest end price point, we offer full on wood stave skin doors, made with the highest quality hard and soft wood 1/8″

real hardwood stave skin. Click here to see some of the most beautiful doors in the world.