Applications -> Building Components -> Doors -> New Door Technology

There is a new concept in Eco-friendly door manufacturing that raises the question:

“Is Sing Door Core a better way to build doors than any other type of door?”

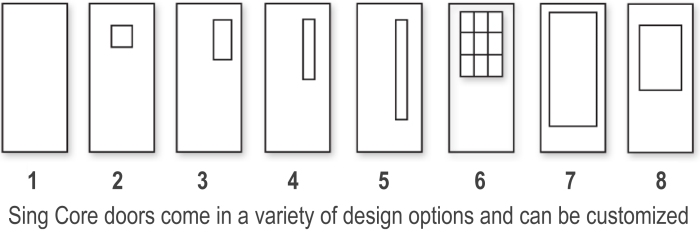

Sing Core’s patented door core has the unique ability to build a true-flat, weather proof/water tight, lightweight door that is stronger than steel and will remain flat for centuries, covered by our 50 year true flat guarantee (compare to other door companies’ warranties that do not cover when used in exterior applications). This new technology allows nearly limitless customizations allowing clients to design any door imaginable in any configuration, style, appearance and/or feature any flat surface material. Our French doors come complete with custom lite opening cutouts to your specifications in any size or shape. Glass doors can be combined with true raised panel doors for the most high precision patented Sing door core (within .006 inch tolerance) affordable American made doors.

Sing Core’s patented door core has the unique ability to build a true-flat, weather proof/water tight, lightweight door that is stronger than steel and will remain flat for centuries, covered by our 50 year true flat guarantee (compare to other door companies’ warranties that do not cover when used in exterior applications). This new technology allows nearly limitless customizations allowing clients to design any door imaginable in any configuration, style, appearance and/or feature any flat surface material. Our French doors come complete with custom lite opening cutouts to your specifications in any size or shape. Glass doors can be combined with true raised panel doors for the most high precision patented Sing door core (within .006 inch tolerance) affordable American made doors.

Sing Core is a new advancement in door building technology that is bringing door-related jobs back to America.

New Sandwich Door vs. Stile & Rail and Wood Door

| SING DOOR | STILE & RAIL and WOOD DOOR | |

| Visually impressive | Visually impressive | |

| True flat | Depends on wood and craftsmanship | |

| Stays flat for centuries | Will warp, bend, twist over time | |

| Weather resistant | Weather exposure will cause door to fail | |

| One-piece construction | Many pieces, each piece is a weak spot | |

| High strength | Moderate strength | |

| Lightweight | Heavy | |

| Insulated | No insulation | |

| Highly customizable | Choose from variety of designs | |

| Affordable | Handcrafted = expensive / import = cheap | |

| Made in the USA | Yes / No |

The idea of building doors with a “sandwich panel” is not new. A sandwich panel consists, basically, of a core material (like a paper honeycomb material found in most inexpensive lightweight doors, or particleboard found inside less expensive heavy doors, while high-end doors may use expensive LVL or solid wood stave core but cannot be guaranteed true flat) sandwiched (glued) between two exterior surface materials – or “skins” – to form a composite panel suitable for creating a door.

The idea of building doors with a “sandwich panel” is not new. A sandwich panel consists, basically, of a core material (like a paper honeycomb material found in most inexpensive lightweight doors, or particleboard found inside less expensive heavy doors, while high-end doors may use expensive LVL or solid wood stave core but cannot be guaranteed true flat) sandwiched (glued) between two exterior surface materials – or “skins” – to form a composite panel suitable for creating a door.

Don’t be fooled by door companies who advertise that their doors contain “honeycomb core,” because they may be using paper honeycomb core which has little core value. Make sure you inquire as to whether your door has patented Sing Core, aluminum core or plastic core. Know what your core value is before you buy your door.

Patented Sing Door Core presents an entirely new set of advantages over other types of core materials that result in insulated doors that last for centuries due to the strength and lightweightness of Sing Core. See table of core comparision.

This new door manufacturing technology makes it possible to create the most versatile doors with a nearly unlimited range of design capabilities without the need of framing or antiquated stile and rail door building methods.

Sing Core could be the least expensive high strength, true flat core material ever invented.

Stile and rail and wood doors are labor intensive causing many of the door companies in the United States to seek off-shore solutions and import doors to reduce the price to the end consumer.

The invention of Sing Core is bringing custom door manufacturing and the jobs associated with it back to the USA. This is due in part to providing American door manufacturers with a base material (Sing Door Core) that enables them to build an insulated, high quality, lightweight, high strength door in any style, without labor intense stile and rail door building methods.

Doors made with Sing Door Core can be made to any size, easily be modified to simulate stile and rail multi-panel design, quickly and easily be custom cut for any size or shape of lite openings for glass placement, and can feature any exterior surface material. See photos.

Doors made of Sing Core shine across the door industry as metal doors, cement board doors, FRP doors and STC sound rated* doors while appearing is door applications as flush doors, French doors, sliding doors, pivot doors, bi-fold doors, entrance doors, interior doors, carriage doors, garage doors and barn doors. Even now, we are working with bullet proof door industry.

All this at a fraction of what it would cost in labor costs to build a stile and rail door made in the USA.

LESS ENERGY – LIGHTWEIGHT – HIGH STRENGTH – SUSTAINABLE

Composite materials, like Sing Core, are leading the wave of new advancements in material science that are taking these new technologies into the future. These revolutionary technologies focus on reduction of energy consumption both during the creation process and in material handling. The newest advancements address common issues associated with weight and strength. Other major concerns are in sustainability. Sing Core excels in all of these, while being extremely affordable and proudly Made n the USA.

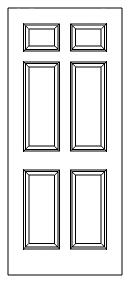

Patented Sing True Raised Panel Doors

High quality Sing Core Doors are affordable compared with other types of stile and rail doors, raised panel doors, French doors, carriage doors, sliding door, etc…

A raised panel door gives you that classic look of a 3-dimensional door that becomes a focal point and statement by the designer and/or homeowner.

Traditional raised panel doors have been made the same way for hundreds of years, in recent years technology has been introduced to simulate this style at an affordable price. Price being a concern has led to more off-shore imports flooding the builders’ supply markets.

Case Study: 125-year-old New York Church

In this 125-year-old church project, the Sing True Raised Panel Door was the perfect solution to address the challenges.

In this 125-year-old church project, the Sing True Raised Panel Door was the perfect solution to address the challenges.

Problem: Exterior wood stile and rail doors fail, bend, warp, twist; requiring continued maintenance and repair.

Solution: Sing True Raised Panel Doors, guaranteed true flat – and stay flat – in exterior application, while matching original 125-year-old raised panel design.

Details: Sing Core expertise in matching client’s specifications and requirements based on patented technology that can deliver true flat, lightweight and high strength doors in any size, that can be guaranteed true flat per your specific performance standards. In this case 6 weatherproof Sing True Raised Panel doors were required to replace 6 125-year-old exterior wood doors in an effort to eliminate regular maintenance and repair challenges of previous wood stile and rail doors.

Specifics: To address the issue of weatherproof and flatness integrity for centuries, the Sing design team’s solution included Sing Panels made of Sing Core door core reinforced with aluminum and a marine grade plywood exterior skin. To match the appearance of original traditional raised panel doors, additional wood trim was added atop the panels to match the 125-year-old previous door design. A perfect match with superior performance eliminating constant maintenance.

- 50 year guaranteed solution

- True Raised Panel Doors

Note: The true flat weatherproof aluminum and marine plywood composite Sing Door is the solution for any exterior door of any size including large doors.

What is a Sing Raised Panel Door?

Sing Core introduces the True Raised Panel Door. The unique design of the Sing Core Raised Panel Door capture the original intent and look of a traditional raised panel door, but offers advantages that cannot be found otherwise.

Other raised panel doors offer little structural integrity. The structure can easily be compromised by little more than kicking the door causing it to break apart at the seams. In contrast, if you were to kick a Sing Core Raised Panel Door you would break your foot.

The secret is in the core of the Sing Core Raised Panel Door. The center of the door is solid as a rock, is resistant to warp, twist or rot and can be guaranteed true flat by build up the surface of Sing panel with molding and decorative raised panels instead the conventional raised panel doors are cave in at some area less than 1/2 inch thick, Sing and cost much less than a traditional raised panel door, which is not really a raised panel door at all in comparison to the Sing Core Raised Panel Door.

All doors start with the basic Sing Flush Door

The best solution according to the Sing Core culture and philosophy is the most affordable solution of using an authentic flush door, though many artists and designers use the Sing Core Flush Door as substrate and add moldings and decorations to meet varying aesthetic specifications.

Add molding for true raised panel features

On the left is the traditional 6 panel “raised panel door” and on the right is the Sing Raised Panel Door that is a true raised panel door, unlike the door to the left. Visually, they look identical, but that is an illusion.

The one on the left is made of 15 pieces of wood assembled together and where the routing is at its narrowest connection-points the door is extremely thin. While visually appealing with a classic look, the door on the left can easily be compromised by kicking the door at any given seam. On the other had an alternative approach is to carve the designs into a solid piece of wood (which is similarly weak at the deepest carve-points).

On the other hand, the Sing door blank is the base used as door substrate, now you can add molding and raised panels on top for the true raised panel door result. Warning: Kick the Sing Raised Panel Door and break your foot, not the door. (We accept no responsibility for injury.) If you can break a sing door, we’ll send you a new one for free.

Plus, the Sing Raised Panel Door gives you all the benefits that come with having an Eco-friendly technologically advanced door that simulates the classic style of the traditional raised panel door.

That’s why many designers who are restoring classic architecture are using Sing Core to replace outdated structural materials and doors. Working with Sing Core, artists and designers are able to duplicate the look and feel of classic materials without having to compromise by loss of energy or unreliableness of traditional building materials.

Then Add Custom Lite Openings for adding glass

Sing Core offers custom cut lite openings in any door to accommodate glass insertion specifications.

Advantages of Sing Core Raised Panel Door vs. conventional raised panel door

1 strength

2 lightweight

3 insulation

4 sound deadening

5 functions —no rattling sound when close the door—solid like rock feeling.

6 less labor to build means less cost for high quality door and production friendly for large order fast delivery.

7 50 years structure guarantee.—almost unbreakable,

8 easy to repair than any other type of door due to the structure Sing core and stress skin structure.

9 can be manufactured to meet any specifications

10 can be guaranteed true flat

How to build Sing raised panel doors

How to install glass? Try our custom cut lite openings for glass installation.

True Raised Panel Door

A new door fabrication technology is changing hundreds of year door making tradition. Now high quality precision (Sing Core tolerance within .0006 inch) doors can be proudly manufactured quickly and easily in the USA. Patented Sing Core can be used in many applications, to include building entire homes.

1. True flat and stay flat

For a very demanding high-end door requiring extremely true flat Sing Core will take your opening task and build your Sing Door according to your expectations. See: How to build a true flat door.

2. Lightweight

2. Lightweight

Sing Core weighs in at 4 to 5 lbs per cubic ft. vs. LVL or solid wood core which weight 35 lbs. to 45 lbs. per cubic ft. (Heavy doors are more difficult to manage, can be dangerous to install. Following installation, may put young fingers and limbs at risk.)

3. High strength

See the strength of Sing Core vs. other cores. Doors made of Sing Panels are one piece construction instead of conventional stile and rail doors joined together by wood dowels.

4. Insulated

Unlike wood or any other solid core door (with little or no insulation), Sing doors offer your choice of insulated materials to fill the torsion box voids to achieve your required specifications for R-value or sound-deadening.

5. All weather doors

Sing Core manufactures true flat weatherproof wood doors that stay flat with proper coating. Due to the unique qualities of patented Sing Door Core, the surface material remains straight and true, will not warp, bend or twist, which causes other doors to crack or water seeps in and the door fails. Also make excellent severe weather doors, like Hurricane Doors**.

6. Any skin

See skin or door surface material choice.

7. Any style

Click here to see door varieties.

8. Any door size or thickness

From regular size door to the largest door (40 ft. in length) and doors over 6 inches thick. Just mentioning “custom size” to other door makers, like stile and rail, will result in extra charges and delivery delays.

9. Fast turnaround

This is where Sing Core shines; everything custom with fastest turnaround on rush jobs. If your job needs a solution now, Sing Core can have your doors (even if you need 700 doors) in less than 24 hours for rush order if we have the necessary components in stock (we maintain an inventory just for rush jobs).

10. Any lite opening cut

Only Sing Core offers custom cut lite openings to accommodate any glass inserts in any shape or size to your exact specifications.

11. Any specialty door

Sound deadening, fire rated, bullet proof…

If you know of any door that is better than a Sing Door, please let us know.

You don’t have to be a door expert to appreciate Sing Core advancements in door making technology. But if you are a door expert; you get it.

- Patented sandwich door

- Lightweight insulated Sing honeycomb door panel

- Insulated honeycomb sandwich door

- French Doors

- Add molding to create stile and rail door appearance

- sing honeycomb stronger than steel lightweight

How to Buy

To order Sing Raised Panel Doors submit an order form either by email, info@singhome.com, or print and fax it to: 360.495.4585. We’ll provide a quote within one business day. If you have questions, please contact us.

Easy Ordering

All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order. Getting a quote for your specialty product, is easy, thanks to our simple online order system.

Bulk Discounts

If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantity and wholesale inquiries are encouraged. Feel free to contact us for more information. Click here for Closeout specials.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Fast delivery: Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

SINGCORE Raised Panel Doors are easy to order. You may choose from our stock panels or order custom sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day. If you have a tight budget, give us a call, we might have an alternative solution tailored to your needs.

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.

**Customer will need to perform lab tests to certify hurricane rating for local code compliance.