Trusted by the leading architects, millworks, and industries

See: How to Build The Perfect 16 ft. Tall White Oak Door

Our materials enable architects & trade professionals to do their best work.

Learn how Brandner Design engineered 10′ tall bi-folding steel doors. We recommend watching this video in full screen. Learn more about their ten foot steel accordion doors

These amazing sliding accordion bi-fold doors are the incredible work of Brandner Design. They represent the ultimate use for Sing Core door cores; highest precision, highest strength, lightest weight, least warpage, most versatile.

Utilized for various applications, Sing Core’s patented panels have established themselves as a professional door core.

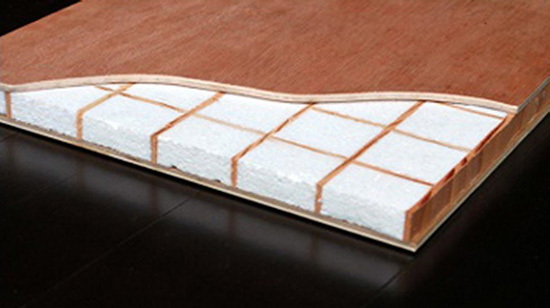

Sing Panels utilize patented Structural Core technology, which is sandwiched between two skins (wood, aluminum, or any other material that can bear weight).

This creates a torsion box, which allows our panel to be stronger, lighter, and truly flat with no warpage.

Proudly made in the USA  Exported World-wide.

Exported World-wide.

1/3 the Weight of Traditional Wood

30 ft. Sing wood pivot doors and Sing post and beams weighing 50% to 87% less than wood; exported and hoisted by crane atop one of the tallest buildings in Bangkok, Thailand. Proudly Eco-friendly, Made in the USA, exported worldwide.

Lightweight and High Strength

Sing Core’s 30 ft. large wood pivot doors are lightweight to be easily handled on the job site with less risk of injury, and less expensive to ship, even in a container overseas. University of Washington independently tested Sing Core panels at over 660 PSI.

50 year warp-free guarantee

Traditional doors warp; our panels don’t. We stand behind our lightweight, high-strength panels with the only 50 year-warp-free guarantee for our professional grade panels.

Insulated and sound deadening

Our patented Sing Core panels prevent separation of the foam and the skin, which provides insulation value and sound deadening qualities. R-values that range between 3.5 and 6.5 depending on the type of foam used. For sound, customize your door to reach the highest STC rating.

Recreate any material

Any substrate (skin) that is capable of carrying a load can be used as a skin with our patented Structural Core. We challenge you to find a lighter, stronger panel than our Cold Rolled Steel Composite Panels.

Environmentally-friendly

We use non-toxic glue for bonding skins to our Core. The structural material of Sing Core is made of 100% renewable material with vertical grain wood fibers.

Made in the USA

All our materials are sourced from the USA. We’re proud to have our products entirely manufactured at our mill near Olympia, Washington. We deliver to anywhere in the world.

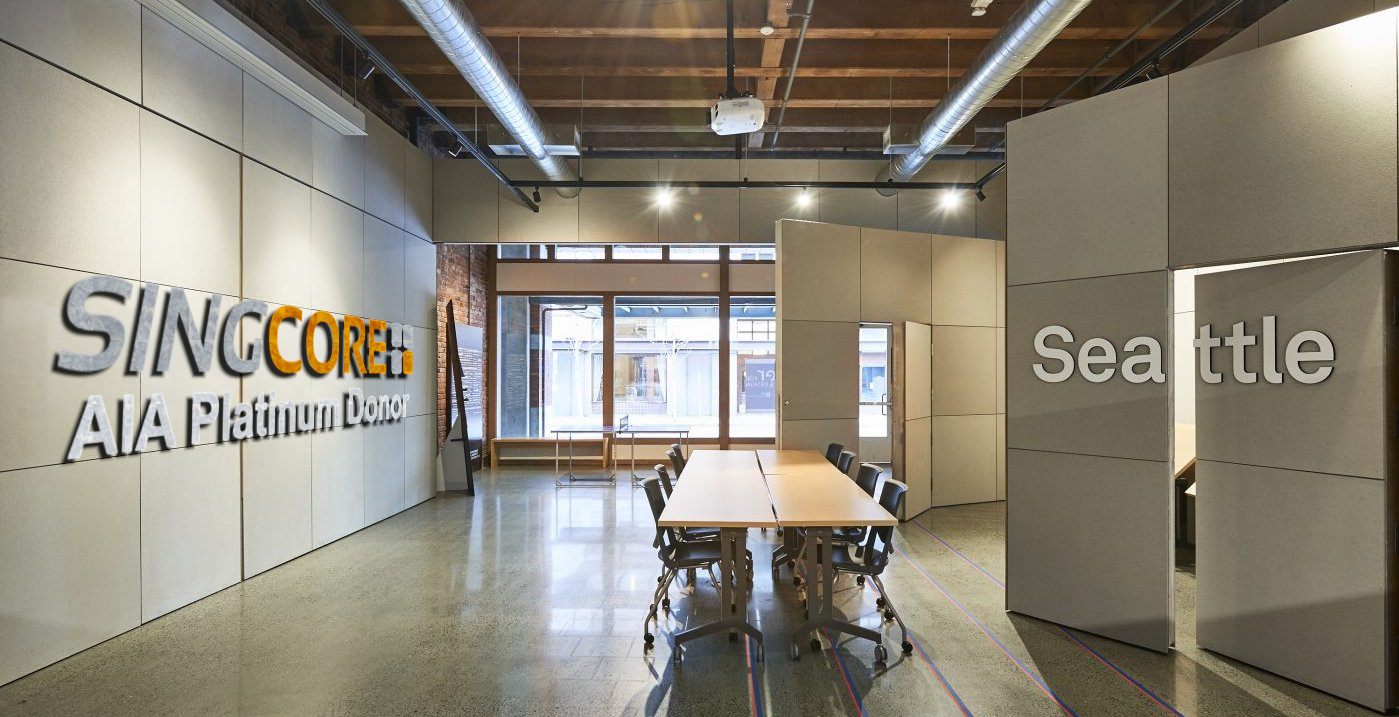

SingCore is proud to support AIA Seattle and the Center for Architecture & Design. Learn how the CFAD utilized SingCore’s flagship custom panels for their 12′ pivot doors.

Learn how your architecture firm, woodwork, or general contractor can utilize and finish our large, custom door cores.

SingCore also specializes in Museum Walls and Trade Show Panels. We’re working to revolutionize industries with more effective, higher performing products.