Sing Sandwich Core is a uniquely designed Eco-friendly efficient way to use as core material for any project yielding lighter weight than traditional solid materials such as wood, plastic, metal, FRP, etc… and with its 660 PSI high strength (stronger than steel pound-for-pound) can help to make nearly anything better and last longer while being more resistant to warp, bend, twist or cup than any other substrate.

Sing Sandwich Core is a uniquely designed Eco-friendly efficient way to use as core material for any project yielding lighter weight than traditional solid materials such as wood, plastic, metal, FRP, etc… and with its 660 PSI high strength (stronger than steel pound-for-pound) can help to make nearly anything better and last longer while being more resistant to warp, bend, twist or cup than any other substrate.

What is Sing Sandwich Core?

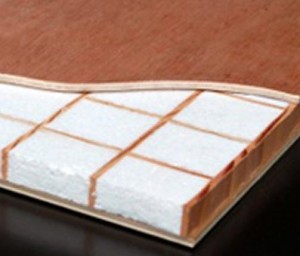

Sing Sandwich Core comes conveniently sized in 2 x 4 ft. pieces (actual finish size is 23.5 inches x 47.5 inches) and can be easily packaged, transported and stored. The structure features patented Sign Core consisting of a natural wood torsion box 2×3 matrix (2 inch x 3 inch boxes) with the voids filled with recycled foam to form a solid substrate sandwiched between two sheets of ¼ inch plywood for easy adhesion using normal carpenter’s wood glue and clamps.

See also: Why and How to Use Sing Sandwich Core

Our most popular standard product available to the public:

Sing Sandwich Core 2×4

48 in. x 24 in.

Making its way into the homes of savvy do-it-yourselfers, shops of woodcrafters with varied degrees of expertise and millworks across the USA, our best selling Sing commodity is the Sing Sandwich 2×4, a 2 ft x 4 ft pre-built reinforced torsion box substrate that is 1.5 inch thick and features a lightweight plywood surface material that is easily bonded with other products. It’s universal convenient 2 ft x 4 ft size is easy to handle and transport and ships in minimum 4-piece bundle.

For the DIY enthusiast who wants to use torsion box technology without all the tedious handcrafting, we’ve done all the hard work for you – plus we’ve packed each torsion box void wall-to-wall with rigid foam insulation, resulting in a super honeycomb structure that is stronger than steel pound for pound (660+ PSI). Easy to handle, no special tools required, cut just like regular plywood.

It’s a standard Sing Sandwich panel 4×8 pre-cut into 4 pieces that you can throw in the front seat of your car and turn into anything for endless applications.

The Sing Sandwich Core is by far the most versatile Sing product to be released to the world.

Note: Sing Sandwich Core is only available in 1.5-inch thick 2 ft x 4 ft size with lightweight plywood facings.

Click here to see how to turn a standard 1.5 inch thick panel into 3/4 inch thick and how to make 1.5 inch panel to 3 inch or thicker Sing sandwich panel or even a thick Sing Panel

Minimum order $4,000 on Sing Sandwich Core (48 in. x 24 in. x 1.5 in.), crate optional.

What is the Difference Between Sandwich Core, Sandwich Panel and Sing Panel?

Sing Sandwich Core

Sing Sandwich Core is our base patented insulated reinforced torsion box core material “sandwiched” between two sheets of lightweight plywood and cut into manageable-sized pieces (2 ft x 4 ft x 1.5 inch) for easy delivery, handling, storage and use as core material or substrate. Sing Sandwich Core can easily be ripped into strips or sliced to any thickness to meet your requirements or specifications without compromising strength when used as core, substrate or filler material. In fact, using multiple layers of Sing Sandwich Core to increase thickness multiplies the strength exponentially. For instance, two layers of 1.5 inch Sing Sandwich Core glued together increases the strength by four (twice the material for 4 times the strength).

Sing Sandwich Panel

The Sing Sandwich Panel is the mother of the Sing Sandwich Core. It has a predetermined size of 4 ft x 8 ft x 1.5 inches with exposed unfinished edges (that means that you will be able to see the exposed Sing Core material as well as some residual glue from the assembly process). All Sing Sandwich panels are made by hand in our factory in the USA. You could create your own Sing Sandwich Core out of your Sing Sandwich Panel, like our millwork partners do. They buy Sing Sandwich Panels by the crate and keep it in stock, then they just rip it into strips to lay up as substrate inside their high end products.

Sing Panel

Like the Sing Sandwich Panel, the Sing Panel is sandwiched between two 4 x 8 pieces of lightweight 1/4 inch plywood with an important distinction; the Sing Panel has embedded solid wood edging (1.5 inch) all the way around the panel on all four sides. Unlike the Sing Sandwich Panel, you cannot see the exposed Sing Core material, all you see is the wood frame which lines up with the edges of the plywood. This makes fastening multiple Sing Panels together a breeze, as the solid wood edges are great for installing hardware or connectors, like cam locks.

Note: Anything can be made with Sing Sandwich Core. You can use Sing Sandwich Core to make your own Sandwich Panel or Sing Panel, or endless items in any size that could not be made more lightweight and high strength any other Eco-friendly way.

How can I use Sing Sandwich Core?

How can I use Sing Sandwich Core?

Using Sing Sandwich Core is so easy. Simply cut into pieces of any size (length, width, thickness) to use as substrate between any two skins and alternatively framed by solid wood (or any other materials you desire).

Slice it in half

Yes, we said it. Slicing any other honeycomb panel in half destroys it, but not Sing Sandwich core, because it is solid and reinforced for even more flexibility. Feel free to slice it into any thickness you like (though we suggest maintaining a minimum thickness of 3/4 inch to maximize the effectiveness of the reinforced torsion box composite core).

Want more strength?

Double the thickness (glue two inch-and-a-half thick pieces together) for a three inch substrate that is 4 times the strength of just one Sing Sandwich Core layer!

The applications where Sing Sandwich Core can be utilized are nearly endless, some examples are:

Woodcrafters use Sing Sandwich Core for substrate in almost anything including butcher block, table tops, counters, shelves, furniture components, etc…

Woodcrafters use Sing Sandwich Core for substrate in almost anything including butcher block, table tops, counters, shelves, furniture components, etc…

Contractors use Sing Sandwich Core for substrate in foundations, floors, walls, doors, ceilings, roofs, etc…

Commercial applications for Sing Sandwich Core include substrate for retail facades, retail displays, temporary offices, office furnishings, cubicles, room dividers, trade show booths, etc…

Industrial uses include substrate for in plant offices, curtain walls, portable clean rooms, modular buildings, storage facilities, refrigeration rooms, ramps, etc…

We encourage you to find new ways to use Sing Sandwich Core, let us know how you might use Sing Sandwich Core.

Why are more people using Sing Sandwich Core?

Composite core has been used widely in new advances of composite material in recent years. Sing Core has the best performance amongst all the core materials used today (click here to see chart of comparision of all types of core material), especially when comparing weight, strength and Eco-friendliness. Sing Sandwich Core is easy to work with without having to invest in expensive machinery and tools (click here to see how to press your own lightweight panel by using Sing Sandwich Panel as a press). Sing Sandwich Core is the patented core material that adds the best characteristics to anything that you build with it such as less warp (Professional Sing Panel is guaranteed not to warp for 50 years) dimensionally stable, easy to machine and less energy to produce and ship thanks to its high strength to weight ratio.

How does it work?

Sing Sandwich Core comes in a handy convenient 2×4 size but can be cut to any dimension to fill any cavity offering the lightweight rigidity and resilience of Sing Core to any product, using it just like you would any other substrate core material.

Use carpenter glue or urethane glue with a cold press which could made of Sing Sandwich Panel or Sing Panel (glue several pc of Sing Sandwich Panel or Sing Panel to make a stronger press). Click here to see how to press your own lightweight panel by using Sing Sandwich Panel as a press.

Want to order by the truckload? Contact us for wholesale price.

Sing Sandwich Core

| Sandwich Panel | Foam | Aluminum | Balsawood | Nomex | Plastic | Cardboard | |

| Insulation | ✓ | ✓ | x | x | x | x | x |

| Sound Deadening | ✓ | ✓ | x | x | x | x | x |

| Lightweight | ✓ | ✓ | ✓ | ✓ | ✓ | x | x |

| Strength | ✓ | x | ✓ | ✓ | ✓ | x | x |

| Solid | ✓ | ✓ | x | ✓ | x | x | x |

| Eco-friendly | ✓ | x | x | ✓ | x | x | ✓ |

| Renewable | ✓ | x | x | ✓ | x | x | ✓ |

| Oversize | x | x | x | x | x | x | x |

| Dimensionally Stable | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Affordable | ✓ | x | x | x | x | x | ✓ |

| Waterproof Upgrade? | x | ✓ | ✓ | x | ✓ | ✓ | x |

| Fire Retardant Upgrade? | x | ✓ | ✓ | ✓ | ✓ | x | ✓ |

| Bullet-proof Upgrade | x | ✓ | x | x | x | x | x |

| Thickness Available | x | x | x | x | x | x | x |

| Skin Options | x | x | x | x | x | x | x |

| Easy to Machine | ✓ | x | x | x | x | x | x |

| Fast Turnaround | ✓ | x | x | x | x | x | x |

Insulation: Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly. This advanced technology used in the aviation industry is now available for use in your home.

Strength: Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength). Sing Core’s superior strength comes from its advanced torsion box design.

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow as they are bonded wall-to-wall and filled with recycled foam for a strong, solid substrate.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat exceeding AWI standards and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due to temperature and moisture change.

Affordable: Even though Sing Core technology is used in high-end applications, we make it affordable for broad use in a large number of applications. Sing Core performance is comparable to any high-end core but could be as little cost as low-end wood product core.

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Standard Sing Sandwich Core Details:

- dimension: 2 ft x 4 ft (in pairs only)

- thickness: 1 ½ inch

- standard 1/4 inch plywood surface

Sing Sandwich Core is so versatile, it has hundreds of applications. You could use this patented sandwich core to build your own lumber, or

Construct a tiny house

Construct a tiny house- World’s smallest house

- Make a door

- Use as flooring

- Ceilings

- Stair treads

- Trade show displays

- Store fixtures

- Signs

- Transportation applications

- Cold storage

- Tables

- Furniture

- … and so much more …