Home -> Products -> Material Options -> Concrete & Cement -> Concrete Formwork

Sing Core is the most installer friendly Insulated Concrete Form (IFC) on the market today. Save yourself time, money and, hassle from start to finish with our (IFC) panels. Sing Core (IFC) are designed to create the strongest structure possible, with less waste and faster install times. Sing Core (IFC) are available in any size dimension. But basic dimensions are 4 x 8, also can be modified by the consumer to any size to fit your need. Sing Core (IFC) system is knock down to disassemble and can be used time and time again, as long as it is maintained properly it will last virtually forever.

Sing Concrete Formwork

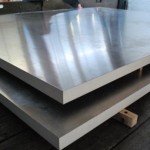

Leading edge concrete contractors are embracing the Sing Core technology especially in terms of aluminum concrete formwork. No other aluminum concrete formwork currently available in the concrete forming industry can compare in terms of lightweight, high-strength and watertight. High Strength Sing Concrete Formwork can be reused many times easily withstanding the pressure of compacted concrete without fail.

AFFORDABLE

Even though Sing Core is much more technologically advanced that other concrete formwork systems, these benefits can be utilized by contractors at huge cost savings as prices start at only $2 per sq. ft. with the added benefit of enhancing your bottom-line by reducing production time, labor and equipment costs. Competitively-priced Sing Concrete Formwork reduces production, equipment and labor costs due to being so lightweight and high strength.

Built-in Structure

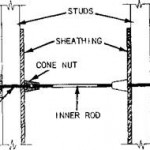

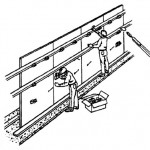

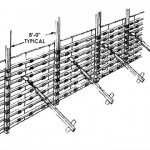

Due to Sing Concrete Formwork’s torsion box filled with foam structural core, our concrete contractors are using only 10% of the snap ties and shoes using our 3 inch aluminum form panels instead of 1 inch standard plywood; plus our Sing Concrete Formwork is 18-times the strength of plywood and weighs only 25% the weight of plywood (yet comparable in price). Sing Concrete Form panels are extreme weather resistant and water proof and easy release.

Increased Safety

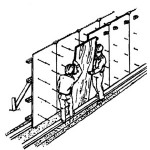

Due to Sing aluminum concrete formwork being so lightweight, panels can be easily transported, assembled/disassembled and erected by labor reducing both heavy equipment costs and operating expenses, also resulting in fewer labor and industry on-the-job-injury claims due to handling.

Concrete contractors are making the change from 1 1/8 inch and ¾ inch MDO plywood to patented Sing aluminum concrete formwork every day as their solution due to the many attributes inherit in patented Sing Core’s superior performance.

High Performance

Sing concrete formwork is the premiere high-performance engineered aluminum formwork system is extremely lightweight and is imbued with unparalleled longevity in heavy use circumstances. This extended life-cycle is realized due to the nearly indestructible nature of patented Sing Core combined with aluminum resulting in aluminum concrete forms that can be easily adjusted for precise formwork placement and reused over and over again without compromise.

Sing Aluminum Concrete Form Comparisons Based on 2″ x 2″ Grids

| Sing Formwork | Timber/Plywood | Aluminum | |

| Affordable | ✓ | ✓ | x |

| Lightweight | ✓ | x | x |

| High-Strength | ✓ | x | x |

| Safety | ✓ | x | x |

| Insulated | ✓ | x | x |

| Interlocking | ✓ | x | ✓ |

| Reinforced | ✓ | x | x |

| Solid | ✓ | ✓ | ✓ |

| Easy Release | ✓ | x | ✓ |

| Repairable | ✓ | x | x |

| Waterproof | ✓ | x | ✓ |

| Custom Size | ✓ | x | x |

| Any Thickness | ✓ | x | x |

| Skin Options | ✓ | x | x |

| Fast Turnaround | ✓ | x | x |

Lightweight, High-strength: Sing Concrete Formwork weighs a fraction of the weight of traditional timber formwork – even less than other engineered formwork systems – yet is many times stronger compared to any other lightweight concrete formwork system. In fact, Sing Core’s compression strength was tested at UW at 660 PSI (stronger than steel pound-for-pound) and could be increased to meet your specifications if necessary.

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly. This advanced technology used in the aviation industry is now available for use in your home.

High strength: Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength). Sing Core’s superior strength comes from its advanced torsion box design.

Insulated Concrete Formwork: In permanent concrete formwork applications, high-performance insulated Sing Concrete Formwork is permanently installed providing both thermal and acoustic insulation. Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications. Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

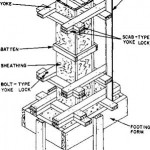

Interlocking Concrete Formwork: Using the thru-bolt fastening method, Sing Concrete Formwork panels can be secured together easily and inexpensively.

Reinforced Concrete Formwork: In permanent installations, Sing Concrete Formwork stays in place to offer reinforcement as well as extreme weather isolation/protection and deterioration-free maintenance to the overall concrete project.

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow as they are bonded wall-to-wall and filled with recycled foam for a strong, solid substrate.

Easy Release and Repairable: The aluminum surface is easily pre-treated with diesel, are waterproof and in the event of damage, can easily be repaired onsite to achieve the original strength of the concrete form panel.

Waterproof: Sing aluminum concrete form material is waterproof including components and zero formaldehyde adhesives used in the manufacturing process.

Custom Concrete Formwork: High-end concrete contractors and architects enjoy high-performance Sing Concrete Formwork’s ability to be custom designed and manufactured with any variety of sizes, thicknesses or exterior skin options to meet the special need of the most demanding products and applications.

Any Thickness available: Sing concrete form materials is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available.

Skin options: Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc…

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Oversize: Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat exceeding AWI standards and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due to temperature and moisture change.

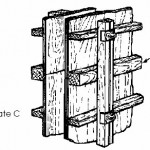

Thru-bolt Joining

One of the most inexpensive and secure ways to join sing panels is by utilizing a simple nut and bolt connection method, especially, if the panels will be routinely or repeatedly assembled and disassembled.

Stainless steel nuts and bolts offer the safety and security when joining sing panels.

- Metal Utility Panels

- Aluminum Benches