Note: This is an archived page and is no longer available. For current information visit us online at: singcore.com

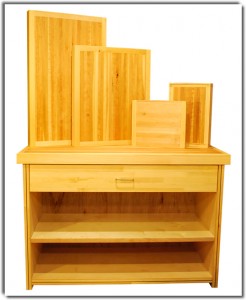

We’ve been supplying Sing Panels to high-end millworks from coast-to-coast for endless wood working applications and much more; see clients list. Now we are inviting you to join our woodworkers and millworks saving you shipping and handling (which could amount to more than the material alone) on standard items.

Standard Sing Products

Standard Sing products include 4 ft. x 8 ft. x 1.52 in. Sing Panels. Our standard products in these dimensions are most commonly used as door and/or table and counter top substrate and a host of other applications. Custom oversize panels and doors will still be available factory-direct from Sing Core.

Special Order

We build Sing panel up to 45 ft. in length by 12 ft. wide in one solid continuous piece or you may edge glue to any dimension. Available in thicknesses from one-half-inch to 6 inches.

New Revolution in Composite Materials

Sing Core is the strongest (see core comparison) low cost core ever invented and is extremely lightweight, with so many other features making Sing Panels the best substitute for solid materials, such as wood, metals, cements, plastics, etc…

How easy is it to use as substrate?

Simply remove the solid substance of those material and replace with Sing Core and, “Voilà!” You have hollowed out the center of the solid material – which is heavy and it is not necessary to enforce the strength due to the stress skin of the unique Sing panel structure – and if you double the thickness of the exterior surface material yields 4 times the strength.

True Dimensionally Stable…

Makes your end result more beautiful and long-lasting than solid wood, engineered wood, metal, cements or plastic…

Makes your end result more beautiful and long-lasting than solid wood, engineered wood, metal, cements or plastic…

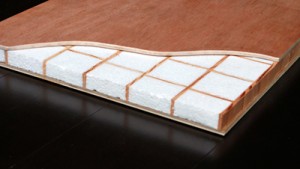

Sing Panels are made of patented Sing Core which is based on wood torsion box filled with foam forming a lightweight, super-strong base material. By adding hardwood veneer or stave you will create a Sing solid wood alternative which appearance and functionality is more high precision. The result is a building material that looks just like solid wood with little or no distortion (solid wood could move according to moisture and temperature change) yet stronger than steel pound for pound.

This revolutionary new high-strength interior structure provides the most dimensionally stable panel. The torsion box structure is made of renewable vertical grain veneer otherwise hollow pockets are packed wall-to-wall with sound deadening insulation recycled foam. The exterior surface materials (or “skins”) of Sing Panels are bonded to the Sing Core structure with zero formaldehyde structural glue to provide the highest quality to meet the demands of high end millworks.

Easy to Build Almost Anything…

… and everything by cutting, slicing and face-gluing to create different thicknesses and dimensions. Sing Panels could be used as core for endless applications in wood working, metal fabricating, concrete, masonry and so many other industries by itself. These composite panels can be cut to any size (cut and rip just like you would any plywood material without special tools or equipment) and used as substrate by adding final skin with common white glue (carpenter glue) and simple clamps to make all types of lightweight high strength wood, fiberglass and metal products.

… and everything by cutting, slicing and face-gluing to create different thicknesses and dimensions. Sing Panels could be used as core for endless applications in wood working, metal fabricating, concrete, masonry and so many other industries by itself. These composite panels can be cut to any size (cut and rip just like you would any plywood material without special tools or equipment) and used as substrate by adding final skin with common white glue (carpenter glue) and simple clamps to make all types of lightweight high strength wood, fiberglass and metal products.

You may slice and sand Sing Panels to your desired thickness and add a new surface skin on the fresh sanded sides of Sing Core with urethane glue (similiar to gurrila glue). Create a thicker panel by sandwiching two Sing Panels together (or just contact us to order specific thickness) for your job requirement.

Replace Traditional Building Materials

Sing Panels are replacing solid wood, particle board, plywood, MDF as the strongest lightweight Eco-friendly core materials ever invented. Patented Sing Panels are most commonly used as door and/or table and counter top substrate and a host of other applications.

Want FREE Shipping & Handling?

Here’s how it works: Simply contact your local plywood supplier and have them contact us. We will work out all the details with them, and they can ship your Sing products to you with your regular orders: you do not pay shipping and handling cost.

Sing Rewards

Just by introducing us to your trusted supplier, we will give you a substantial discount on your next order with free shipping, no packaging costs and we will also send you a free gift to say, “thank you,” for making it easier – and less expensive – to bring sing Core to your door.

Get Sing products on demand while saving on packaging and shipping costs, you pay less, and get what you want when you want with your regular shipments for your favorite supplier at the same low price that you get (or less) buying direct, without the delay.

We Need Your Help

It works better both ways… 1) You help your customer build the best lightweight high-strength products at lower cost, and 2) Your supplier inventories and delivers to you at your convenience.

Build a Better World

We work together to help building a better world by using Eco-friendly long-lasting Sing Sandwich and Sing Panels. Contact us today to help make the world a better place.

Lumber Yards

We have an open invitation to all lumber and specialty plywood suppliers, to contact us today to add Sing products to your inventory.