Sing Core melds the best of two worlds, the lightweight scientific development and the best of nature’s natural resources into Eco-friendly high-tech, space-age advanced composites.

Sing Core melds the best of two worlds, the lightweight scientific development and the best of nature’s natural resources into Eco-friendly high-tech, space-age advanced composites.

Foam core panels have served the building and construction community well, helping address the issues of weight in large projects. Used as a substrate, foam core panels are lightweight and somewhat rigid and can be glued to a variety of materials to strengthen or give it a more strong appearance.

To increase the strength of foam core you must increase the density, which increases both the weight and price of the lightweight core and is not good for our environment.

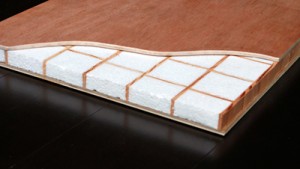

Enter inventor Peter sing’s new invention: Sing Core. The revolutionary new material that takes the positive attributes of foam core material combines it with the best of nature and high-end traditional woodworking craftsmanship, to reveal a spectacular hybrid.

Using the science behind foam materials, the repurposed natural wood grain from nature and the best of woodworking craftsmanship, Sing Core is the most significant improvement in the building and construction trades in the last decade.

Using the science behind foam materials, the repurposed natural wood grain from nature and the best of woodworking craftsmanship, Sing Core is the most significant improvement in the building and construction trades in the last decade.

While traditional torsion box interior has been an effective woodcraftsman’s solution for centuries, it was reserved only for extremely high-end applications, due to the intense labor of building the torsion boxes used in the inner structure. By combining the strength of torsion box and filling the voids that would normally only be filled with air with recycled foam Sing Core raises the bar on being extremely lightweight and super-strong

Foam cores used in aerospace engineering have low compression strengths, yet Sing Core tests out at 660 PSI (and can be increased to meet your specifications), that is stronger than steel pound for pound (even bullet proof doors don’t test that high). Due to its unique design, Sing Core is much stronger when compared to other materials.

Sing Core is so much more affordable than custom woodwork because this patented technology can generate high-performance torsion box inexpensively and efficiently, especially if you are considering incorporating it as a lightweight substrate material for a large project, like a door, a table top, conference table, etc… See more applications.

Sing Core can use a wide variety of foam materials to meet your most demanding specifications including (but not limited to) polyurethane, polystyrene and styrofoam. Upgrading to closed-cell foam, makes Sing Core a perfect match for marine applications, like decking materials.

Sing Core Compared to Foam Core:

|

Sing Core |

Balsa Wood |

|

| Eco-friendly? |

Yes |

No |

| Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste. | ||

| Renewable? |

Yes |

No |

| The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material. | ||

| Strength? |

Yes |

No |

| Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength) | ||

| Oversize? |

Yes |

No |

| Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length. | ||

| Affordable? |

More |

Less |

| Even though Sing Core technology is used in high-end applications, we make it affordable for broad use in a large number of applications. Sing Core performance is comparable to any high-end core but could be as little cost as low-end wood product core. | ||

| Thickness available? |

More |

Less |

| Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available. | ||

| Bullet-proof upgrade? |

Yes |

No |

| In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core. | ||

| Skin options? |

Yes |

No |

| Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc… | ||

| Easy to machine? |

Yes |

No |

| Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening. | ||

| Fast turnaround? |

Yes |

No |

| In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA. | ||

Sing Core is the basis of the Sing Sandwich panel, Sing Panels and Sing Post and Beam and is available in any exterior surface material including metal panels, with which you can solve most any structural challenge especially in terms of lightweight, high strength and Eco-friendly building materials, guaranteed.

How to Buy

To order Sing Foam Core Alternatives submit an order form either by email, info@singhome.com, or print and fax it to: 360.495.4585. We’ll provide a quote within one business day. If you have questions, please contact us.

Easy Ordering

All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order. Getting a quote for your specialty product, is easy, thanks to our simple online order system.

Bulk Discounts

If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantity and wholesale inquiries are encouraged. Feel free to contact us for more information. Click here for Closeout specials.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Fast delivery: Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

SINGCORE Foam Core Alternatives are easy to order. You may choose from our stock panels or order custom sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day. If you have a tight budget, give us a call, we might have an alternative solution tailored to your needs.