The experts at Sing Core have years of experience in solving the difficult issues that face architects, designers and contractors when face with challenges dealing with uncompromised structural integrity and weight restrictions. Oftentimes the secret to the proper solution depends in a combination of Sing Core and various surface materials. The skin or surface material is not only the appearance of the Sing panel, but it is critical for the true flatness and smoothness which easy to use as paint grade, strength and affects the overall weight. Click here for architectural specs.

Sing Panel comes in three different varieties: Standard, Professional and Hot-Press-Ready-Series

1 True Flat

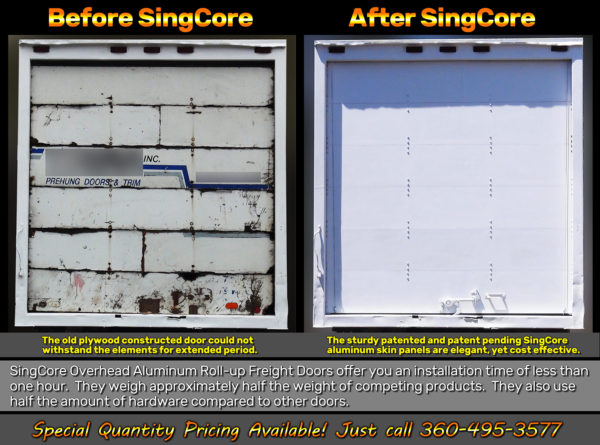

Surface skin should use same material if possible. The surface material should use less porous materials to avoid moisture absorption. Aluminum is superior to none moisture absorbing MDF, Masonite, etc… The aluminum can be paint grade by using acid etching primer, or other alternatives include adding plywood, particle board, MDF on top of the aluminum using a hot or cold press with veneer or wood stave to create a wood grain doors or panels.

2 Thickness of Skin or Surface Materials

We use material as thin as .020 aluminum, HPL to 3/4 inch, AB plywood and marine grade plywood is the most integrous choice due to the non-void high quality veneer used as plywood core. The most common skins include 1/8” plywood, 1/4″ plywood and 3/8” plywood. But if you are in need of a one-inch thick door that is 20 ft in length then aluminum will be the best option. Please contact us if you need help.

3 Strength

The strength depends on the thickness of the panel. For instance, if you double the thickness it will be 4 times the strength. The thickness of the skin could make up the extra strength but increasing the thickness to gain strength will result in added weight, which may compromise the end result. The answer is usually a combination of matching the right Sing Core width with the appropriate surface material to achieve the desired results without loss of structural integrity or unnecessary additional weight.

4 Sing Core Grids Size Selection

There are 3 types of Sing Core grid sizes:

- LARGE: 16 square inch

- MEDIUM: 9 sq inch, and

- SMALL: 4 square inch

The smaller grids have higher compression strength. Mostly common used are 3 inch x 3 inch at 9 sq inch or equivalent. For extremely lightweight panel, the largest grids size will be the proper choice.

5 Foam Options

Sing Core standard foam which is used to bond and fill the voids in the internal torsion box structure is constructed with EPS foam w/R-value=3. When clients require more stringent values to meet their specification in terms of better sound deadening, higher insulation value, or water resistance then urethane foam will be the idea material to make up the foam part of the Sing Core structure.

6 Solid Wood or Solid Material Implants

The most common materials used in patented Sing Panels includes solid wood edges and standard implant materials are Douglas Fir or soft wood, and poplar. In addition to solid wood edges, other options include aluminum, plastic and FRP (amongst other custom options that can be matched to your specifications) are commonly used to seal the edge to match the skin material. Unless specified otherwise 12″ x 2″ lock blocks are inserted on both sides 28″ from the bottom of the door.

7 Oversized Sing Panels

We can build panels 10 ft wide 50 ft in length on one solid piece that are nearly seamless with extremely high precision. The joined areas will not move according to the moisture or temperature change. This is an example of our integrous true flat technology.

The low cost solution to build a large door is to use our standard 4 ft x 8 ft panel to join together or edge glue, or use plywood strips connect those Sing Panels together. This type of large panel will not be as flat as our factory built oversize Sing Panel but it will be lightweight and adequately stronger than the most common stile and rail solid lumber doors or walls.

8 Fire Retardant Doors

Sing Core fire retardant doors use 3 mm magnesium board or cement board, ceramic tile and light gauge sheet metal as skin(s) to create fire barriers. These could include added wood stave or wood veneer as final skin for the wood grain or paint grade finish. See specifications.

9 Water Resistance

We suggest using urethane Sing Core for water resistance. Urethane foam is closed-cell which does not absorb moisture and/or water. The adhesives we use are water resistance glues. The skin choice for water resistance will usually be aluminum, FRP or marine grade with proper coating.