- Lightweight honeycomb insulated door panel

- Hot rolled lightweight honeycomb door panel

- Super strong insulated sandwich panel

- Lightweight strong steel panel

- Big honeycomb sandwich door

- Patented lightweight steel door panel

- Super strong steel panel

- Large lightweight hot rolled honeycomb panel

- Patented lightweight honeycomb door panel

- Hot rolled steel panel

- Lightweight insulated steel door panel

- Sing honeycomb insulated door panel

- Insulated honeycomb steel door panels

- Lightweight super strong metal elevator doors

- Patented honeycomb doors

- Strong lightweight steel panels

- Non warping lightweight honeycomb door panel

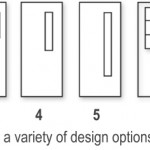

- Metal lightweight door varieties

- Sing honeycomb lightweight core panel

- Insulated lightweight door core