Overview: What Are Wood Stave Door Skins?

Sing Core’s wood stave door skins give you the authentic look and feel of real solid wood with the structural stability of our patented lightweight core. Unlike traditional solid wood doors that warp or twist over time, our stave skins remain flat, strong, and guaranteed warp-free for 50 years.

Explore all Sing Core door applications »

Domestic Walnut Wood Grain Large Door

See: How to Build The Perfect 16 ft. Tall Walnut Door

Why Choose Wood Stave Door Skins?

-

Authentic solid wood appearance – Stave skins use real wood planks (⅛″–¼″ thick), sanded and matched for a premium look.

-

Warp-free performance – Bonded to our patented Sing Core substrate, movement is locked down to prevent twisting or bowing.

-

Lightweight strength – Our engineered torsion-box structure is stronger than steel pound-for-pound yet easy to handle.

-

Ideal for oversized doors – Build pivot doors, sliding doors, and entry systems at massive scale without warping.

-

Guaranteed longevity – Backed by our 50-year structural and warp-free warranty for professional installations.

How Sing Core Builds Warp-Free Stave Doors

-

Core Technology

Our torsion-box honeycomb core provides a lightweight but rigid foundation, resisting stresses that cause warping. -

Real Wood Staves

Staves are precision-cut planks of your chosen hardwood species (oak, walnut, cherry, mahogany, maple, teak, ash, and more). -

Edge Matching

Panels can be trimmed with solid wood edges for a seamless appearance. -

Bonding Process

High-performance adhesives permanently bond staves to the core under controlled pressure and temperature. -

Finishing

Panels can be sanded, stained, painted, or clear-coated — giving the exact look of solid wood, but with far superior stability.

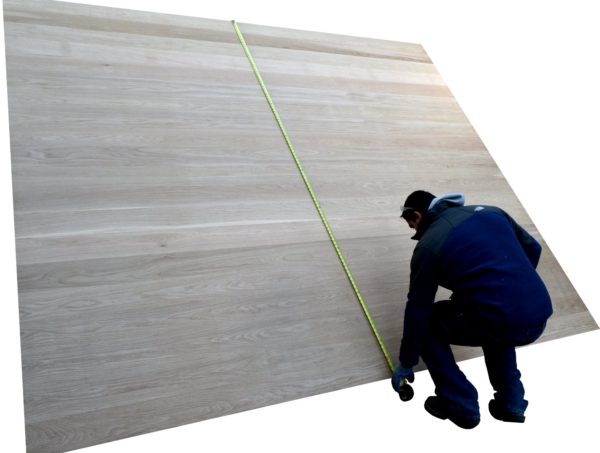

Here’s an example of a pair of 10 x 12 big oak doors, 3-inches thick. These are made using solid oak wood stave (or planks) trimmed thin at 1/8-inch and applied to patented Sing Core engineered substrate.

The face staves or planks are expertly applied and nearly seamless. If done any other way, these face staves will separate or crack due to movement of the surface area, but because Sing Core does not move, this surface area will remain in pristine condition thanks to the warp-free contribution to the large wooden door industry.

The secret to making a big oak door, like this, look like a solid oak door is to use matching oak grain stiles and rails for framing. So instead of edge-banding on the panel sides, you see solid oak wood edges which gives this the impression of being a big solid oak wood door.

Wood Stave vs. Veneer or Plywood Skins

| Feature | Wood Stave Skin | Veneer |

|---|---|---|

| Appearance | Premium solid-wood look and texture | More uniform, less depth of grain |

| Stability | Requires Sing Core to prevent movement | Naturally stable with cross-layers |

| Matching | Random match | Book, slip, sequence, etc. |

| Longevity | Refinishable and repairable | Veneers are thinner and harder to repair |

Compare all Sing Core skin options »

Applications for Wood Stave Door Skins

-

Oversized pivot doors

-

Grand entry doors

-

Interior statement doors

-

Custom architectural doors

-

Sliding and barn-style doors

-

Commercial and residential projects

The Domestic Difference

Let it be known that all of our products here at SingCore are 100% handmade in America. We make everything by hand right here at our factory in sunny McCleary, WA. Order now to see the difference!

Frequently Asked Questions (FAQ)

What is a wood stave door skin?

It’s a layer of real wood planks bonded over Sing Core’s patented substrate, creating a door that looks like solid wood but is warp-free.

How thick are the wood staves?

Typically between ⅛″ and ¼″, depending on species and project requirements.

What’s the difference between stave and veneer doors?

Staves are thicker real wood planks, offering more depth and authenticity. Veneers are thinner slices and less durable.

Can these doors be oversized?

Yes — with Sing Core inside, wood stave doors can be built in sizes up to 40′ without warping.

Do wood stave doors come finished?

We supply unfinished door slabs. Your millwork, contractor, or architect applies the final finishing and hardware prep.

Ready to build your next project with the beauty of real wood and the stability of Sing Core?

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Fast delivery: Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

- Pivot door

- Rift white oak pivot door

- Rift white oak pivot door

- Pivot door

- Black walnut sliding door

- Pivot door

- Sliding door

- rift white oak pivot door

- Rift white oak pivot door

- Pivot door

- Pivot door

- Pivot door