When you need a large door that doesn’t warp, especially a sliding door made of wood, then look to Sing Core for you salvation. No one is able to guarantee our wooden sliding doors don’t warp like we do, with a warp free 50 year guarantee.

How do you stop a wooden door from warping?

The easy answer is to buy Sing Core for your door. Our patented light weight torsion box material is able to withstand extreme conditions and maintain perfect straightness over the life of the door. Wood can always warp but sing core never will, despite being a wood and foam core. The aerospace inspired construction methods push the capability of wood to beyond the strength of steel pound per pound and lighter than an equivalent wood door of traditional construction

How do you straighten a warped interior door?

There is no easy way to straighten a typical wood warped door. But Sing Core’s patented and patenting pending aluminum stiffener technology, found in all “professional” grade wooden sliding doors we make, allows warped doors to rebound.

The process is simple to un-warp a Sing Core wooden sliding door that may have warped during transport or during storage before finishing and installation.

- Support the wooden sliding door on it’s side in a dry area

- Allow the panel to sit with equal circulation on both sides for 3-5 days

- Enjoy your perfectly straight sliding door panel

Once sealed and installed, perfect straight Sing sliding door panels will never warp.

Does staining wood prevent warping?

Staining wood does not prevent warping. Sing panels, once sealed with an appropriate wood sealer, will never warp. Traditional wood doors, however, are prone to warping even after sealing due to aging effects of the wood.

What causes cabinet doors to warp?

Traditional cabinet doors generally warp because of uneven moisture infiltration due to near by water sources such as sinks, showers, and steam from cooking. Everyone knows that wet wood tends to warp.

Similarly, if the wood used in the cabinet is not perfectly dry or has natural imperfections then the panel will warp no matter how it is treated.

Unlike traditional cabinets, Sing Core does not derive it’s strength from lumber, but from our patented core. This core is impervious from warping, is much lighter than a traditional wood cabinet door, and provides better insulation.

Barn doors that won’t warp

If you want a barn door that stays perfectly straight no matter what, you will have extra difficulty if you use a pure wood door. Barn doors only have 2 points of contact per panel, and therefor cannot benefit from mechanical stability of 3 or more points of contact.

Sing Doors, although not the cheapest on the market, can save time and money because you can be confident that our attractive natural wood panels are backed inside with a space age technology.

How to build a barn door that won’t warp

To build barn door that won’t warp:

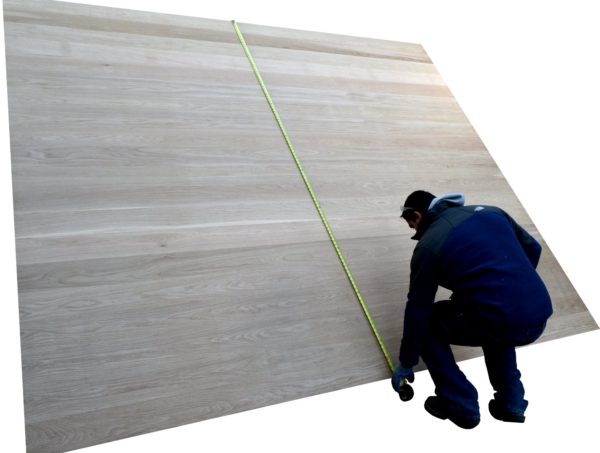

- Order a sing core panel of your chosen length, width, and thickness

- Choose your skin thickness and finish

- Finish to you choice of color the raw wooden sing panel

- Mill out and install hardware

Why do doors warp

Doors warp because of uneven humidity causing dimensional change in the panel. Additionally, imperfections in the wood and stress on the door over time can lead to warpage.

Sing doors combat all these issues with out patented Sing Core material that is stronger than steel by weight and the times lighter than wood. All our “professional” grade panels come with a pure lifetime 50-year structural guarantee. Doors with excessive warpage will be replaced, with only minimal questions asked.

Order Today

If you have any questions about how Sing Core can help with your project, please contact us directly!