Sing Core has been working with several universities regarding custom doors lately, such as with the University of Idaho and their arena door, the University of Alabama and a sorority house door, and now the University of Maryland with a custom sliding door for one of their lounges.

The University of Maryland worked with the brilliant people at USAM to get a large custom sliding door for their Heritage Community lounge room, and they reached out to Sing Core to make that work. Sing Core and USAM worked together to create a beautiful 3 piece modular sliding door. This door can separate into three panels along the sliding track, allowing for a custom setup to the walkway. It can also be completely opened and closed in order to really open up the area.

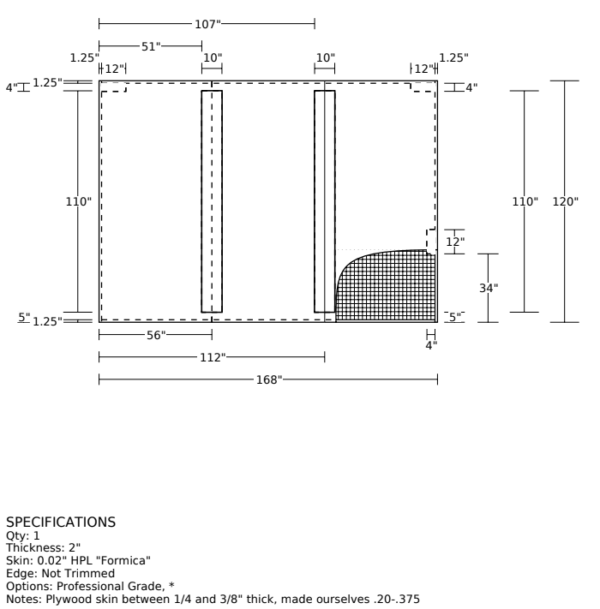

This large sliding door measures 168 inches wide by 120 inches tall, and is 2 inches thick. It contained splines to stiffen the panels and further improve the structural integrity, as well as a Formica finishing panel to give it that gorgeous end result. The door parts slide along an upper rail, which provides smooth and reliable operation.

This large sliding door measures 168 inches wide by 120 inches tall, and is 2 inches thick. It contained splines to stiffen the panels and further improve the structural integrity, as well as a Formica finishing panel to give it that gorgeous end result. The door parts slide along an upper rail, which provides smooth and reliable operation.

This lounge room is in Pyon-Chen hall, one of two areas that make up the Heritage Community at UMD. It is a multipurpose location, intended to suit all sorts of recreational and student needs. Due to the location, the unique modular aspect, and the traffic, the designers of this door needed to make sure they got a high quality, durable, and long lasting product. That is why they went with Sing Core, and we are honored that they did!

Sing Core panels have many benefits over traditional door making methods, but there are three main ones that relate to a project like this: strength and durability, weight, and lifespan.

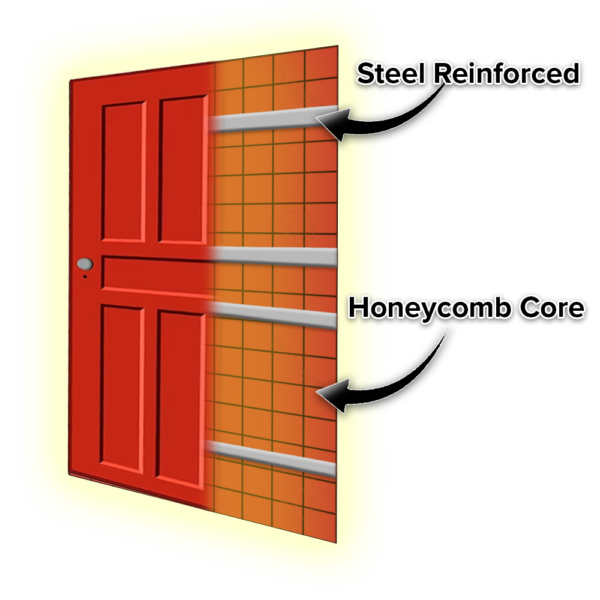

Sing Core doors are incredibly strong and durable, though surprisingly lightweight. This is possible due to the patented honeycomb core used within every Sing Core door. This honeycomb core provides exceptional strength and impact resistance, while also remaining amazingly lightweight. Where a traditional door panel may take several people to haul and install, most Sing Core panels can be carried by only two people, and even one if the panel is sized right.

Sing Core doors are incredibly strong and durable, though surprisingly lightweight. This is possible due to the patented honeycomb core used within every Sing Core door. This honeycomb core provides exceptional strength and impact resistance, while also remaining amazingly lightweight. Where a traditional door panel may take several people to haul and install, most Sing Core panels can be carried by only two people, and even one if the panel is sized right.

The patented core and high grade materials used also give our doors outstanding durability, preventing many of the damages that would otherwise leave a door ugly or unusable. Especially being in a high-traffic area such as a university lounge room, durability, impact resistance, and longevity are vital. Heavy traffic walkways can see increased damage to the doors and walls around them. Sing Core doors aren’t easily damaged, and if they do receive a ding or scratch, they are easy to repair. In addition, all Sing Core panels are guaranteed to be warp-free for 50 years, which is unheard of in the door market. Warped doors are a massive problem, and unfortunately, many doors can eventually warp, regardless of the care put into making them. Sing Core doors, however, are guaranteed to never warp, and that is all thanks to the unique construction used to make them.

Sing Core is thrilled to have had the chance to work on this amazing project. Thanks again to the University of Maryland and the talented design and installation teams, as this would not have been possible without them.

Sing Core is thrilled to have had the chance to work on this amazing project. Thanks again to the University of Maryland and the talented design and installation teams, as this would not have been possible without them.

If you have a large custom door project you’re working on, don’t hesitate to contact Sing Core for a quote!

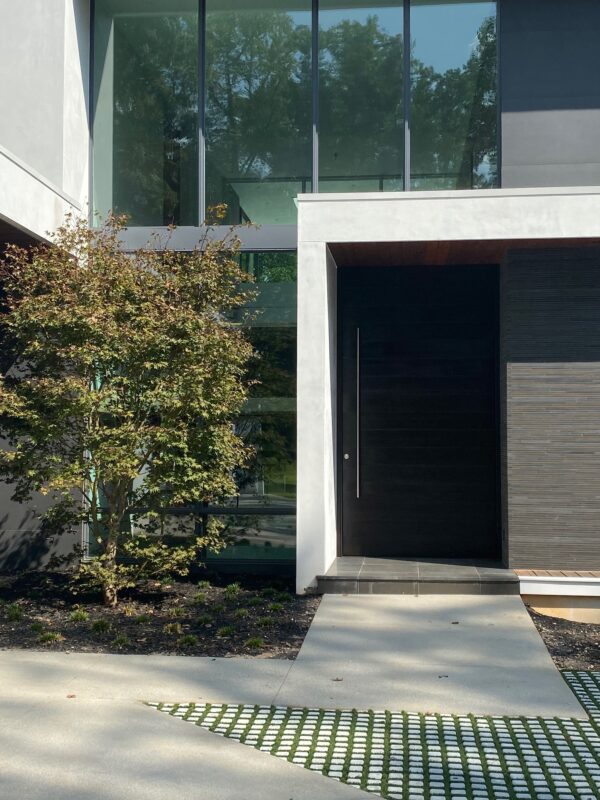

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work.

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work. A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core.

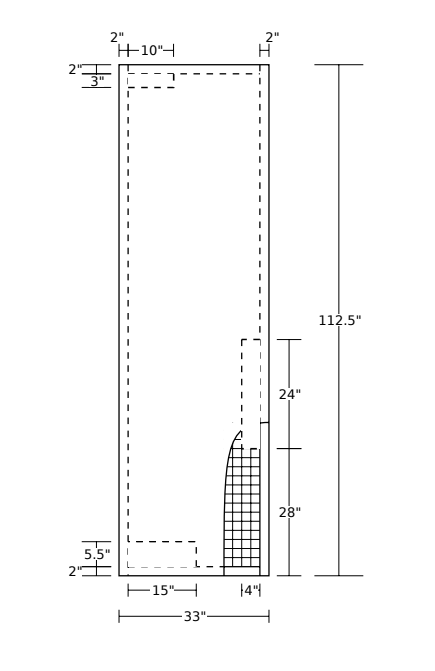

A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core. The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures. Unparalleled Strength and Lightweight Construction

Unparalleled Strength and Lightweight Construction Versatile Design Options

Versatile Design Options Large Panels and Seamless Integration

Large Panels and Seamless Integration Durability and Low Maintenance

Durability and Low Maintenance