In the realm of architecture and design, the pursuit of innovation and efficiency is paramount. To cater to the evolving needs of modern businesses, architects are constantly seeking ways to upgrade office spaces, enhancing functionality, aesthetics, and overall productivity. One useful material in this aspect is Sing Core, a revolutionary material that offers unparalleled versatility and durability. In this article, we will explore how architects can harness the power of Sing Core to upgrade their business clients’ offices, creating spaces that inspire and support success.

In the realm of architecture and design, the pursuit of innovation and efficiency is paramount. To cater to the evolving needs of modern businesses, architects are constantly seeking ways to upgrade office spaces, enhancing functionality, aesthetics, and overall productivity. One useful material in this aspect is Sing Core, a revolutionary material that offers unparalleled versatility and durability. In this article, we will explore how architects can harness the power of Sing Core to upgrade their business clients’ offices, creating spaces that inspire and support success.

Reinventing Interior Layouts

One of the primary challenges architects face when upgrading office spaces is modifying existing layouts to accommodate changing requirements. With Sing Core, architects gain the freedom to redefine interior spaces effortlessly. This lightweight yet incredibly strong material can be used to create movable walls, partitions, and modular systems. By leveraging the flexibility of Sing Core, architects can transform large open areas into smaller workstations or meeting rooms, ensuring optimal space utilization and privacy while maintaining a seamless and aesthetically pleasing environment.

Enhancing Acoustic Performance

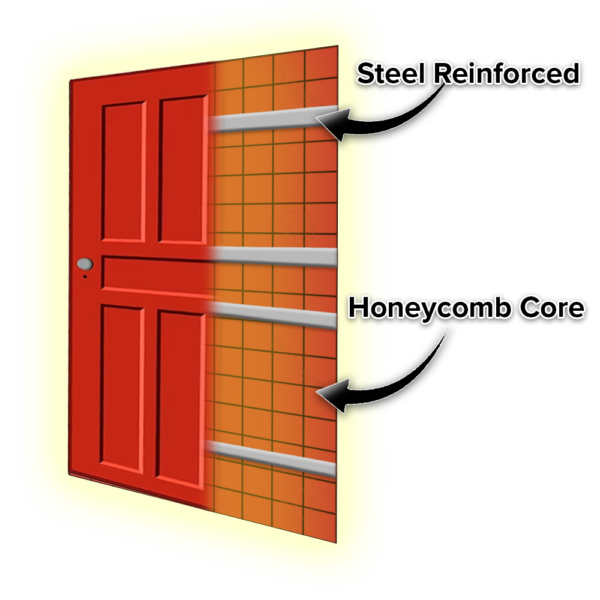

Noise pollution can significantly impact employee focus and productivity. Architects can utilize Sing Core to address acoustic challenges and create a serene and productive work atmosphere. Sing Core’s unique construction, featuring an insulated honeycomb core, acts as a sound barrier, effectively reducing noise transmission between different areas of the office. By incorporating Sing Core panels into doors, walls, or other office components, architects can design spaces that promote concentration and collaboration, ultimately benefiting the overall performance of the business.

Creating Inviting Reception Areas

A welcoming and visually striking reception area leaves a lasting impression on clients and visitors. Sing Core can help architects elevate the design of these crucial spaces. With the variety of options and customizability, architects can utilize Sing Core to make beautiful entryways and doors, awe inspiring structures, and more. The material’s ability to accommodate various finishes and veneers also allows architects to unleash their creativity and craft stunning focal points that reflect the business’s brand identity.

Incorporating Sustainable Elements

As sustainability becomes increasingly vital in architectural design, Sing Core provides architects with an eco-friendly solution for office upgrades. Sing Core is manufactured using sustainable materials and techniques, making it an environmentally conscious choice. Furthermore, the material’s high strength-to-weight ratio reduces the need for excessive structural supports, minimizing the consumption of additional resources. By incorporating Sing Core into office renovations, architects can contribute to a greener future while ensuring their clients’ spaces are in line with sustainable practices.

Conclusion

Architects play a crucial role in transforming office spaces into efficient, visually pleasing, and productive environments. By harnessing the potential of Sing Core, these professionals can upgrade their business clients’ offices with remarkable ease and creativity. From flexible interior layouts to functional workstations, enhanced acoustics to inviting reception areas, and sustainable designs, Sing Core offers a wealth of possibilities for architectural upgrades. Embracing this innovative material empowers architects to unlock new realms of design, ultimately shaping workspaces that inspire and support business success in the ever-evolving corporate landscape

Introduction

Introduction