When it comes to exterior doors, durability, security, and aesthetic appeal are paramount. SingCore exterior doors stand out in the market as a revolutionary choice, offering a unique blend of strength, lightweight construction, and eco-friendly materials. In this article, we will explore the innovative features that make SingCore exterior doors a top choice for homeowners and builders alike.

Unparalleled Strength:

SingCore exterior doors are renowned for their exceptional strength. The secret lies in the core material – a patented Sing Core. This core is a composite of vertical grain torsion box structural grid and foam, resulting in a door that is incredibly lightweight yet stronger than traditional solid wood doors. This design ensures that the doors are resistant to warping, bending, and other common issues associated with wooden doors, providing long-lasting performance and structural integrity.

Lightweight Construction:

One of the standout features of SingCore exterior doors is their lightweight construction. Traditional solid doors can be heavy and cumbersome, making installation and daily use a challenging task. SingCore’s innovative design significantly reduces the weight of the door without compromising on strength. This makes installation easier and ensures that the doors are easy to handle on a day-to-day basis. The reduced weight also puts less stress on hinges and hardware, contributing to the overall longevity of the door.

Eco-Friendly Materials:

SingCore is committed to sustainability, and their exterior doors reflect this dedication. The use of eco-friendly materials in the construction of SingCore doors makes them an environmentally conscious choice. The torsion box core is made from renewable wood sources, and the manufacturing process minimizes waste. Choosing SingCore exterior doors not only benefits homeowners with a high-quality product but also contributes to a greener and more sustainable future.

Versatile Design Options:

SingCore exterior doors are not just about strength and durability; they also offer a wide range of design options to suit various architectural styles. Homeowners and builders can choose from a variety of finishes, veneers, and styles to match the aesthetics of any project. Whether you prefer a classic wood finish or a modern, sleek look, SingCore doors can be customized to meet your specific design preferences.

In the world of exterior doors, SingCore stands out as a game-changer. With a focus on strength, lightweight construction, eco-friendly materials, and versatile design options, SingCore exterior doors provide an innovative solution for those seeking a durable, reliable, and aesthetically pleasing entryway. As the demand for sustainable and high-performance building materials continues to grow, SingCore doors represent a forward-thinking choice for residential and commercial projects alike.

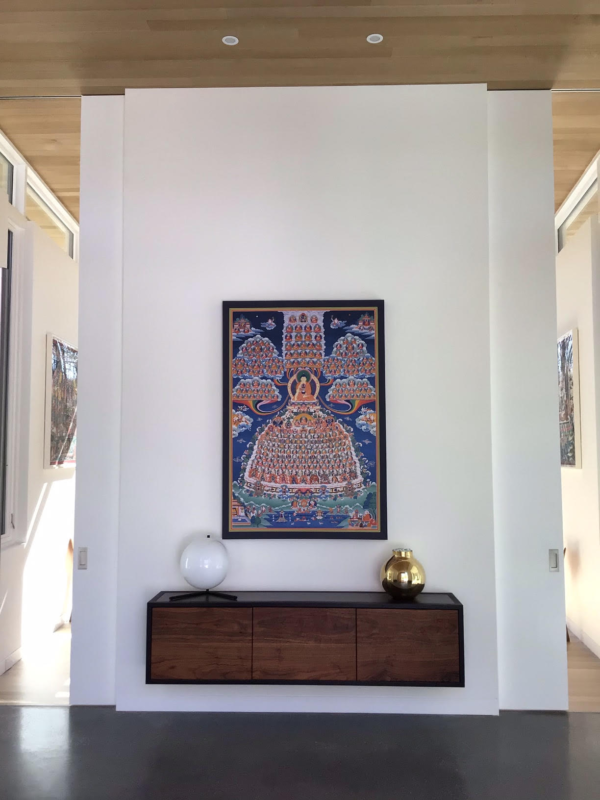

People often think of doors as simple barriers or entryways, but at Sing Core, we know that a door can be much more than that. Doors can be elegant accents to a room’s design, or a seamless way to change a room’s layout. If done right, they can even be part of a room’s main design feature, such as in the example we’re showing you today.

People often think of doors as simple barriers or entryways, but at Sing Core, we know that a door can be much more than that. Doors can be elegant accents to a room’s design, or a seamless way to change a room’s layout. If done right, they can even be part of a room’s main design feature, such as in the example we’re showing you today. Because Sing Core panels are made with a honeycomb core,

Because Sing Core panels are made with a honeycomb core,  A Sing Core door can be ordered to nearly any shape or size, and are strong, lightweight, and durable. One major concern with large doors

A Sing Core door can be ordered to nearly any shape or size, and are strong, lightweight, and durable. One major concern with large doors

Design Flexibility

Design Flexibility

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work.

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work. A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core.

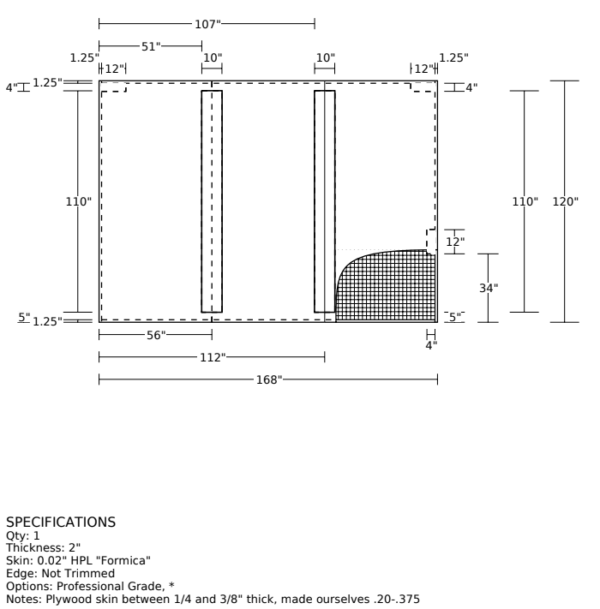

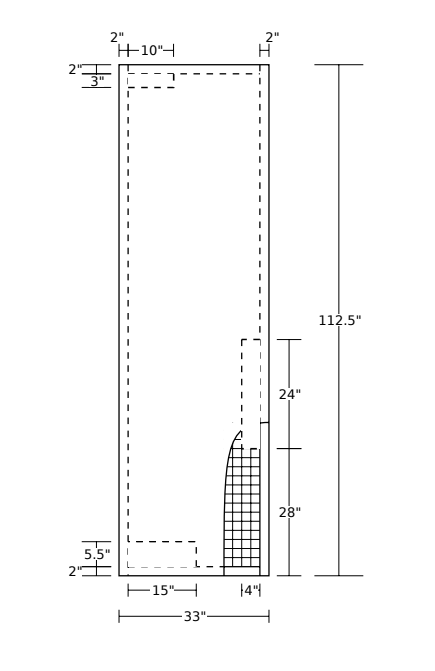

A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core. The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

Barn doors constructed with Sing Core offer

Barn doors constructed with Sing Core offer  Weight and Handling Issues

Weight and Handling Issues Warping and Moisture Resistance

Warping and Moisture Resistance Precision and Customization

Precision and Customization When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

Solid Wood Doors

Solid Wood Doors

Steel Doors

Steel Doors