Doors are not just functional elements in our homes and buildings; they are also essential design features that add character and aesthetic appeal. As architectural styles evolve and become more intricate, the demand for uniquely shaped doors has increased. However, crafting such doors presents a multitude of challenges for manufacturers. In this article, we will explore the difficulties of making shaped doors and how Sing Core can overcome these challenges.

Complex Shapes and Structural Integrity

Complex Shapes and Structural Integrity

One of the primary challenges in creating shaped doors is maintaining structural integrity while accommodating intricate designs. Traditional door materials such as solid wood or fiberglass often struggle to retain their shape and stability when subjected to unusual configurations. As a result, manufacturers face limitations in terms of design possibilities.

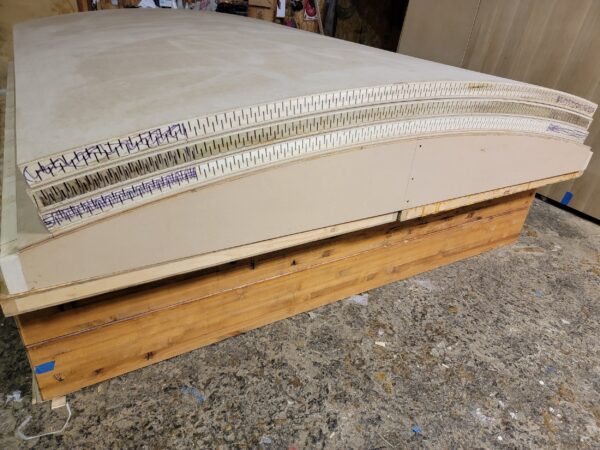

Sing Core, on the other hand, does no have these limitations. Composed of a lightweight yet incredibly strong honeycomb core, Sing Core has remarkable stability, even in complex shapes. Its unique construction incorporates a torsion box grid structure that ensures optimal strength, rigidity, and dimensional stability. This characteristic allows for the creation of doors with elaborate curves, arches, and other non-standard shapes.

Weight and Handling Issues

Weight and Handling Issues

Another significant challenge in crafting shaped doors lies in their weight and the subsequent handling difficulties. Traditional materials used for door construction, such as solid wood or metal, can be heavy and unwieldy. This poses challenges during installation, transportation, and everyday use.

Sing Core panels address this issue by being exceptionally lightweight while maintaining their structural integrity. By utilizing a combination of advanced composite materials and a honeycomb grid core, Sing Core achieves an impressive strength-to-weight ratio. As a result, shaped doors made with Sing Core are significantly lighter than their traditional counterparts, making them easier to handle and reducing strain during installation.

Warping and Moisture Resistance

Warping and Moisture Resistance

Traditional doors, especially those made of solid wood, are prone to warping and distortion when exposed to fluctuations in temperature and humidity. This is a persistent challenge for shaped doors, as the irregular surfaces and edges increase the potential for warping.

Sing Core panels, however, are guaranteed to be warp-free. Their high quality design and strong core eliminates the risk of warping and distortion. The honeycomb core of Sing Core also plays a vital role in maintaining dimensional stability over time. This ensures that shaped doors retain their intended form, even in challenging environmental conditions. In addition, all Sing Core panels come with a 50 Year Warp-Free and Structural Guarantee, so you can trust our panels to hold strong for many years to come.

Precision and Customization

Precision and Customization

Crafting shaped doors requires precise measurements, intricate detailing, and customization to meet specific design requirements. Traditional manufacturing methods often struggle to achieve the necessary precision, leading to inconsistencies and compromises in the final product.

Sing Core panels can be completely customized and are made with the necessary precision to meet the unique specifications of any design. This level of customization allows for the creation of truly one-of-a-kind shaped doors that fulfill the vision of architects, designers, and homeowners.

Conclusion

The challenges of creating shaped doors are significant, but with Sing Core, the industry has found a game-changing solution. By combining remarkable strength, lightweight construction, warp resistance, and precise customization capabilities, Sing Core panels enable the production of stunning shaped doors that were once thought to be impractical or unattainable. As architectural designs continue to push boundaries, Sing Core proves to be an invaluable asset in meeting the demands of modern construction and design, revolutionizing the industry in the process.