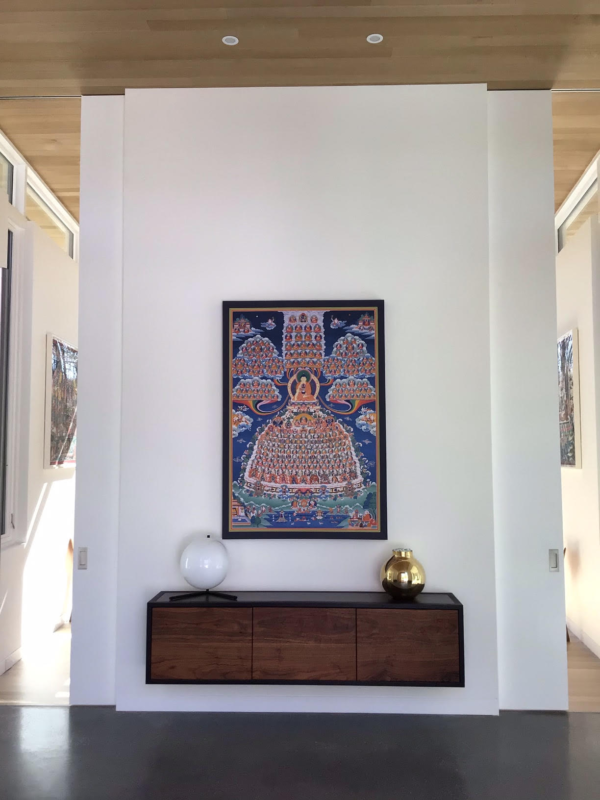

People often think of doors as simple barriers or entryways, but at Sing Core, we know that a door can be much more than that. Doors can be elegant accents to a room’s design, or a seamless way to change a room’s layout. If done right, they can even be part of a room’s main design feature, such as in the example we’re showing you today.

People often think of doors as simple barriers or entryways, but at Sing Core, we know that a door can be much more than that. Doors can be elegant accents to a room’s design, or a seamless way to change a room’s layout. If done right, they can even be part of a room’s main design feature, such as in the example we’re showing you today.

This customer needed a way to separate two areas of the house, but was fairly limited in their options due to their design preference. Due to the height of the room, a standard door would not work unless they expanded on the center wall, which would majorly damage the flow and beauty of the room. A normal sliding door would work, but the dimensions would be incredibly difficult to get right. The door would have to be incredibly tall, yet narrow, which would need to be custom made. If this was done with traditional materials, the doors would likely be too heavy to work reliably, and could damage their hardware. Sing Core, however, was a great solution.

Because Sing Core panels are made with a honeycomb core, they are incredibly lightweight, yet still very strong. This means that the custom doors would still be sturdy and long lasting, but due to their low weight, they’d also be easy to use and be far less likely to damage their hardware. In fact, each of these doors only weigh 200 pounds, despite being over 13 feet tall.

Because Sing Core panels are made with a honeycomb core, they are incredibly lightweight, yet still very strong. This means that the custom doors would still be sturdy and long lasting, but due to their low weight, they’d also be easy to use and be far less likely to damage their hardware. In fact, each of these doors only weigh 200 pounds, despite being over 13 feet tall.

These twin pocket doors measure 40 inches wide by 158 inches tall, and are 2.5 inches thick. This tall and narrow design worked beautifully for the room, though is definitely a non-standard size. Getting a door like this without having it custom made would be impossible, but luckily Sing Core specializes in large, high end custom doors.

A Sing Core door can be ordered to nearly any shape or size, and are strong, lightweight, and durable. One major concern with large doors is the possibility of warping, which gets exponentially more likely, and often exponentially worse, with larger doors. In the case of this project, even just a slight warp could ruin the entire system. A little bend or twist could leave a door stuck in its pocket, or scraping the side as it is opened and closed, damaging both the door and the wall nearby. There are many ways a warp can hinder or ruin a door, and often, warps are irrecoverable. Sing Core doors are guaranteed to never warp, and we can make that claim due to our innovative and patented honeycomb core. In fact, each door panel comes with a 50 Year Warp-Free and Structural Guarantee, so you can rest easy without worrying about your door failing on you.

A Sing Core door can be ordered to nearly any shape or size, and are strong, lightweight, and durable. One major concern with large doors is the possibility of warping, which gets exponentially more likely, and often exponentially worse, with larger doors. In the case of this project, even just a slight warp could ruin the entire system. A little bend or twist could leave a door stuck in its pocket, or scraping the side as it is opened and closed, damaging both the door and the wall nearby. There are many ways a warp can hinder or ruin a door, and often, warps are irrecoverable. Sing Core doors are guaranteed to never warp, and we can make that claim due to our innovative and patented honeycomb core. In fact, each door panel comes with a 50 Year Warp-Free and Structural Guarantee, so you can rest easy without worrying about your door failing on you.

Sing Core is thrilled to have had the chance to work on this beautiful project, and we hope to work on your next amazing project with you. Submit a quote request on our website to learn what we can do for you!

Design Flexibility

Design Flexibility

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work.

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work. A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core.

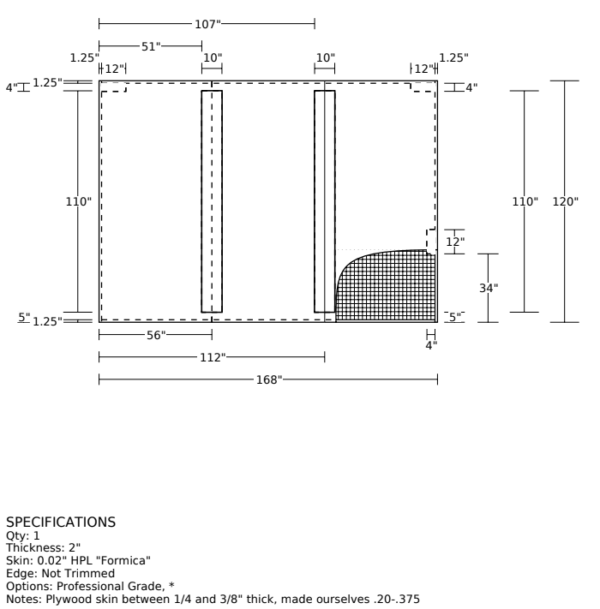

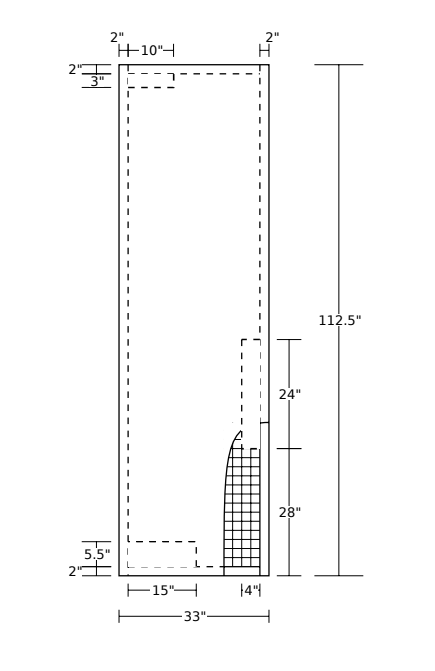

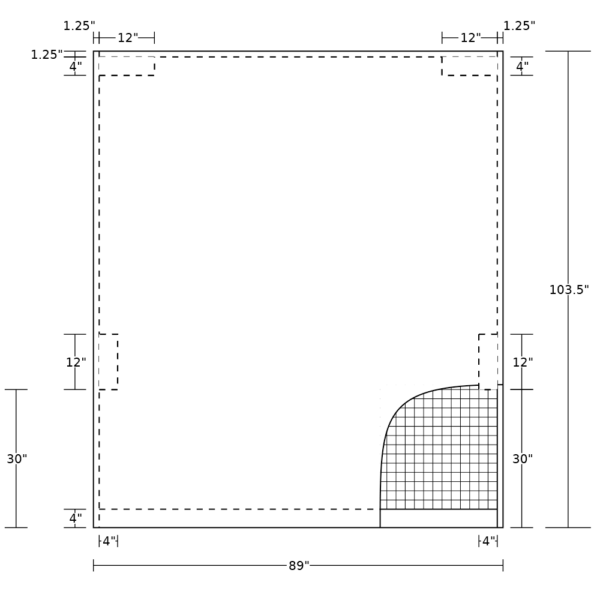

A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core. The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

Barn doors constructed with Sing Core offer

Barn doors constructed with Sing Core offer  Weight and Handling Issues

Weight and Handling Issues Warping and Moisture Resistance

Warping and Moisture Resistance Precision and Customization

Precision and Customization When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

Solid Wood Doors

Solid Wood Doors

Steel Doors

Steel Doors

The Project

The Project

In the realm of architecture and design, the pursuit of innovation and efficiency is paramount. To cater to the evolving needs of modern businesses, architects are constantly seeking ways to upgrade office spaces, enhancing functionality, aesthetics, and overall productivity. One useful material in this aspect is Sing Core, a revolutionary material that offers unparalleled versatility and durability. In this article, we will explore how architects can harness the power of Sing Core to upgrade their business clients’ offices, creating spaces that inspire and support success.

In the realm of architecture and design, the pursuit of innovation and efficiency is paramount. To cater to the evolving needs of modern businesses, architects are constantly seeking ways to upgrade office spaces, enhancing functionality, aesthetics, and overall productivity. One useful material in this aspect is Sing Core, a revolutionary material that offers unparalleled versatility and durability. In this article, we will explore how architects can harness the power of Sing Core to upgrade their business clients’ offices, creating spaces that inspire and support success.