Customizing something gives you the freedom to add or take away certain aspects of an item. At Sing Core we offer the ability to do just that, by making custom doors for all your structures. We provide doors for any purpose, such as oversized cabinet doors, large doors, garage doors, pivoting doors. The list goes on. If you can’t seem to find those perfect doors, whether new construction or a home remodel, here at Sing Core, we can make it happen. Or if you are looking for a pivoting door for your entrance, we have you covered. No matter the task, we can service your door needs.

Below are some of the many options Sing Core offers as a skin choice or in other words the surface material.

|

Paint Grade |

Metal |

Wood Grain |

Wood Stave |

FRP Fiberglass |

|

Galvanized Steel |

Aluminum |

Metal .20 in to.125 inch aluminum |

HPL Formica |

Masonite |

|

Cold Rolled Steel |

Hot Rolled Steel |

Magnesium Board |

Marine Grade Plywood |

MDF |

|

Plastic |

Stainless Steel |

Fiberglass |

Concrete |

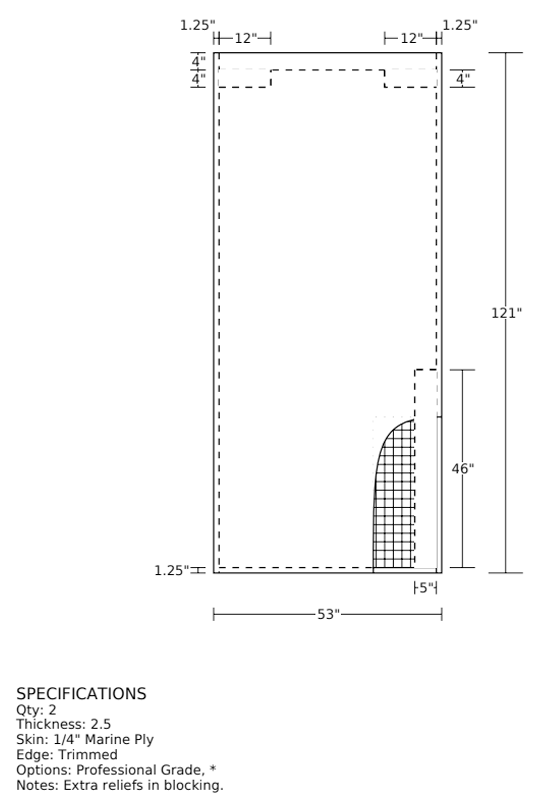

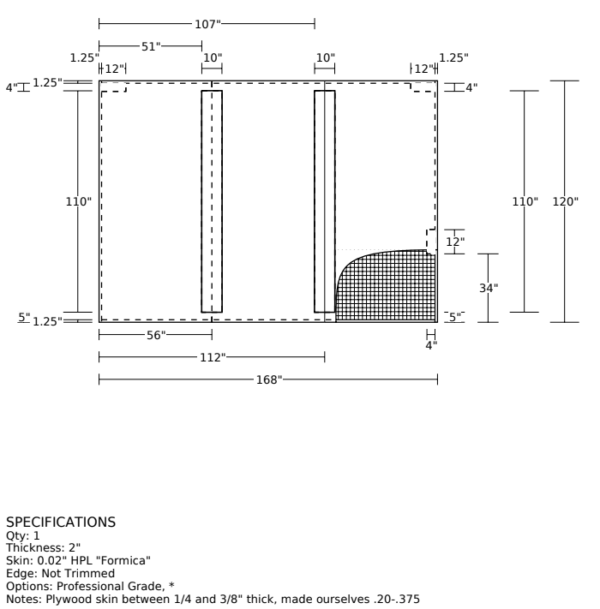

Ceramic |

Some other options we have here at Sing Core are window and light cutoffs. Sing Core provides Sing panels with window and door pre-cut and ready for installation. We will cut 1/8 larger in width and 3/16 inch wider in length to fit your window glass. We build a frame using 1.25 inch solid wood to your specifications. The standard ready-to-ship panel condition is, “untrimmed.” All untrimmed edges are 1/2 inch over width and 1/2 inch over length. After trimming, your Sing Panel will be 1/2 inch less.

|

|

When customizing, the concern most often brought up is the weight. Though many leading competitors try to work with the design of the customer, they have trouble keeping it light and movable. At Sing Core our door panels are up to 80% less in weight allowing for a beautiful door without the hassle of being too heavy.

Once these doors are complete the next choice is having a pivoting door or a hinged door. For a hinged door the hinges attach to both the wall and the door itself, allowing the door to swing open and shut. Hinged doors can usually be installed rather easily, are simple to operate, and most maintenance can be done by the home or business owner. For many small to standard sized doors, hinges work great. Pivot doors usually are mounted from the top and bottom near one side of the door, as opposed to the side. This attachment can be imagined as a pole running through the door, and the door rotates around said pole. Pivot doors are much more stable choices when it comes to large and heavy doors, and standard sized doors as well. Because they are not attached and completely suspended from one side, they have far less impact on their hardware. In addition, pivot doors are usually made with more resilient hardware to begin with, so your door will remain beautiful and functional for a very long time. Every Sing Core Door comes with our 50 year structural guarantee.

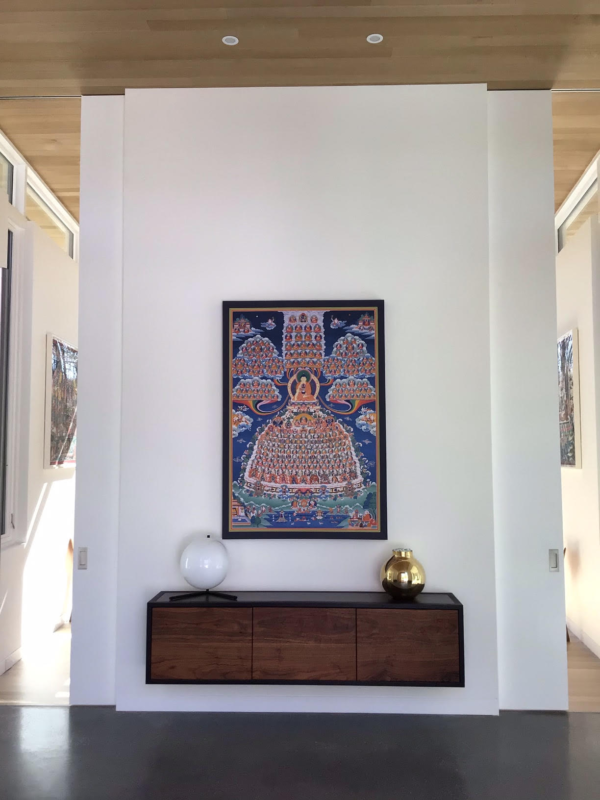

People often think of doors as simple barriers or entryways, but at Sing Core, we know that a door can be much more than that. Doors can be elegant accents to a room’s design, or a seamless way to change a room’s layout. If done right, they can even be part of a room’s main design feature, such as in the example we’re showing you today.

People often think of doors as simple barriers or entryways, but at Sing Core, we know that a door can be much more than that. Doors can be elegant accents to a room’s design, or a seamless way to change a room’s layout. If done right, they can even be part of a room’s main design feature, such as in the example we’re showing you today. Because Sing Core panels are made with a honeycomb core,

Because Sing Core panels are made with a honeycomb core,  A Sing Core door can be ordered to nearly any shape or size, and are strong, lightweight, and durable. One major concern with large doors

A Sing Core door can be ordered to nearly any shape or size, and are strong, lightweight, and durable. One major concern with large doors

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work.

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work. A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core.

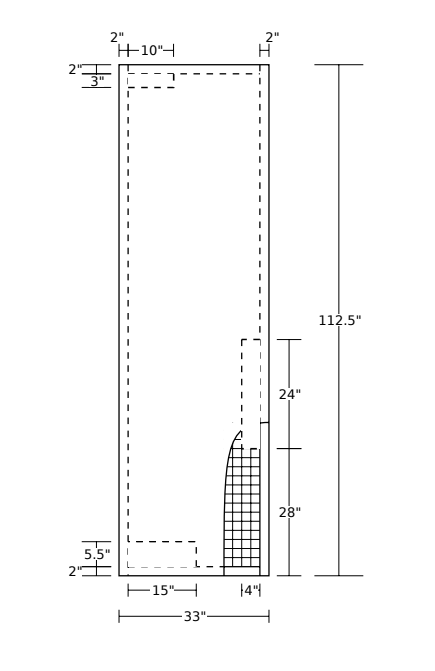

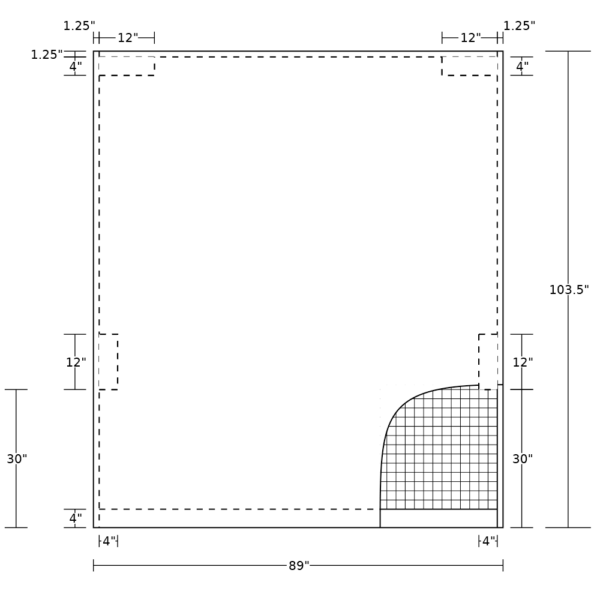

A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core. The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures. Complex Shapes and Structural Integrity

Complex Shapes and Structural Integrity Weight and Handling Issues

Weight and Handling Issues Warping and Moisture Resistance

Warping and Moisture Resistance Precision and Customization

Precision and Customization

The Project

The Project

When it comes to large industrial doors, choosing the right material is crucial for architects and construction professionals. These doors must withstand heavy usage, harsh environments, and demanding performance requirements. Sing Core has emerged as the best choice for large industrial doors, offering unmatched strength, durability, and a range of benefits that set it apart from other options in the market. In this article, we will explore why Sing Core stands out as the ultimate choice for architects and construction professionals when it comes to large industrial doors.

When it comes to large industrial doors, choosing the right material is crucial for architects and construction professionals. These doors must withstand heavy usage, harsh environments, and demanding performance requirements. Sing Core has emerged as the best choice for large industrial doors, offering unmatched strength, durability, and a range of benefits that set it apart from other options in the market. In this article, we will explore why Sing Core stands out as the ultimate choice for architects and construction professionals when it comes to large industrial doors.

Expanding Design Possibilities

Expanding Design Possibilities Durability and Longevity

Durability and Longevity