When it comes to large industrial doors, choosing the right material is crucial for architects and construction professionals. These doors must withstand heavy usage, harsh environments, and demanding performance requirements. Sing Core has emerged as the best choice for large industrial doors, offering unmatched strength, durability, and a range of benefits that set it apart from other options in the market. In this article, we will explore why Sing Core stands out as the ultimate choice for architects and construction professionals when it comes to large industrial doors.

When it comes to large industrial doors, choosing the right material is crucial for architects and construction professionals. These doors must withstand heavy usage, harsh environments, and demanding performance requirements. Sing Core has emerged as the best choice for large industrial doors, offering unmatched strength, durability, and a range of benefits that set it apart from other options in the market. In this article, we will explore why Sing Core stands out as the ultimate choice for architects and construction professionals when it comes to large industrial doors.

Unparalleled Strength and Durability

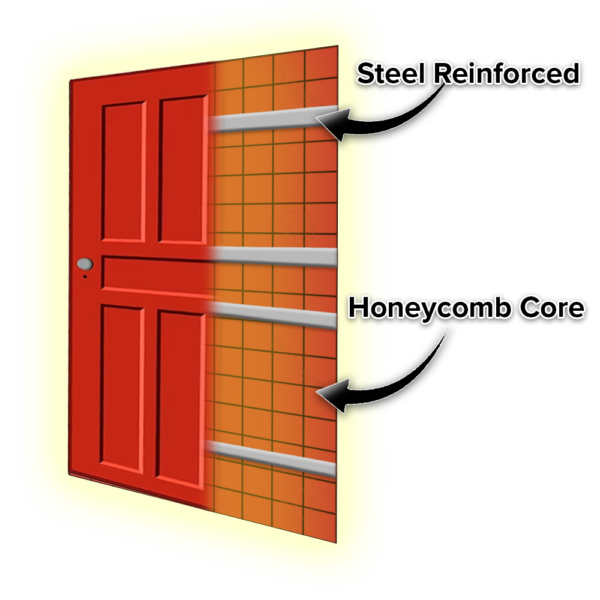

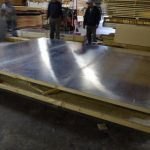

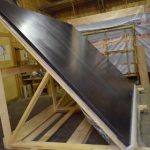

Sing Core’s superiority lies in its exceptional strength and durability. Large industrial doors constructed with Sing Core are designed to withstand the toughest conditions, maintaining their structural integrity over time. The honeycomb core is made with high grade hardwood and insulation, creating a solid foundation that can withstand immense pressure and resist warping. This remarkable strength ensures that the doors remain robust and reliable even in the face of heavy use and challenging environments.

Lightweight Design, Enhanced Efficiency

Despite their outstanding strength, Sing Core doors are surprisingly lightweight. This advantage revolutionizes the installation process, reducing strain on door hardware and making handling and transportation significantly easier. Furthermore, a lighter door is easier to use once installed, especially in the case of large industrial doors. Massive metal sliding doors can be a pain to open and close, but with Sing Core, the door would still be easy and smooth to operate.

Unmatched Insulation Properties

Energy efficiency is a top priority for industrial and commercial applications, and Sing Core excels in this aspect. These doors incorporate exceptional insulation properties, reducing heat transfer and improving energy efficiency. The honeycomb core within Sing Core doors acts as a powerful insulator, maintaining stable interior temperatures and minimizing heat loss or gain. This insulation prowess ensures optimal energy efficiency in industrial spaces, reducing reliance on climate control systems and lowering energy costs in the long run.

Customization for Optimal Design

Every architectural project is unique, demanding doors that fit specific design requirements. Sing Core understands this need and offers extensive customization options. Architects and construction professionals can tailor the size, shape, and finish of the doors to match their vision precisely. This level of customization ensures seamless integration of the doors into the overall design aesthetic, enhancing the visual appeal and functionality of the industrial space. Sing Core’s commitment to customization allows professionals to achieve their design goals while maintaining the exceptional quality and performance the brand is known for.

Versatility and Adaptability

Sing Core’s versatility extends beyond large industrial doors. The innovative core technology can be applied to various architectural elements, including partitions, wall panels, ceilings, and more. This adaptability allows designers to create cohesive and visually appealing spaces with consistent quality throughout. By utilizing Sing Core for multiple applications, professionals can streamline the sourcing process and maintain design consistency across projects, further enhancing efficiency and ensuring an excellent end result.

Conclusion

When it comes to large industrial doors, Sing Core reigns supreme as the ultimate choice for architects and construction professionals. With its unparalleled strength, durability, lightweight design, energy efficiency, customization options, and versatility, Sing Core offers a comprehensive solution that outperforms conventional alternatives. By selecting Sing Core for large industrial doors, professionals can ensure optimal performance, longevity, and aesthetic appeal for industrial spaces. Sing Core’s commitment to innovation and excellence solidifies its position as the top choice for architects and construction professionals seeking to deliver outstanding results in large industrial door construction.