All Professional Sing Panels are guaranteed not to warp and maintain full structure strength for 50 years. There are no maximum size limitations. For doors that exceed shipping or building entry constraints a Sing Core Patented Modular Large Door System is the solution.

All Professional Sing Panels are guaranteed not to warp and maintain full structure strength for 50 years. There are no maximum size limitations. For doors that exceed shipping or building entry constraints a Sing Core Patented Modular Large Door System is the solution.

Custom sizes and thicknesses available. We are experts in manufacturing true flat panels and non-warping panels for very large doors, walls, tables and more…

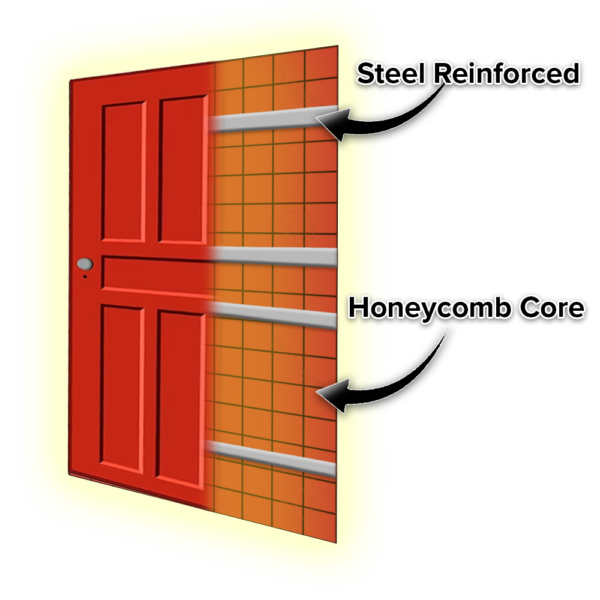

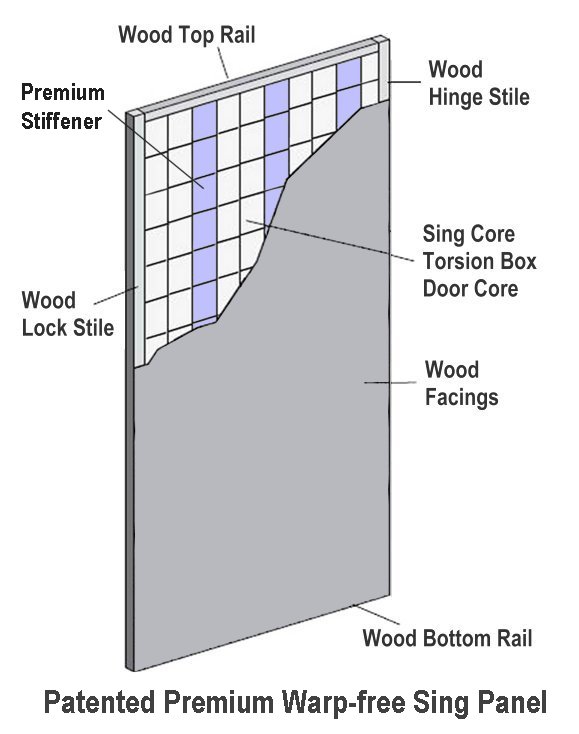

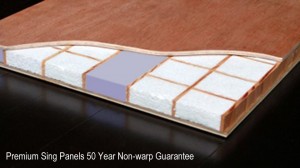

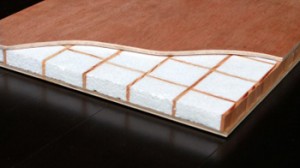

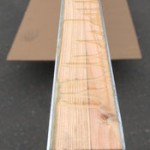

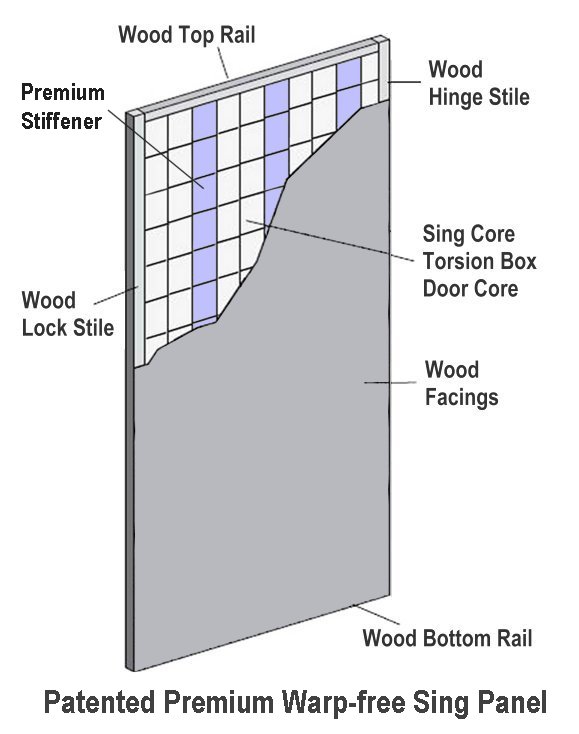

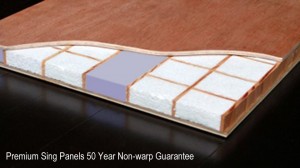

Professional panels are made of a wood torsion box grid with foam inserts, professional stiffeners, a solid wood frame with blocking for hardware, and two matching skins “sandwiching” the core.

Professional Sing Panel

Professional Sing Panel

Build your own non-warp door without the extended delivery time

The Professional Sing Panel takes the standard Sing Panel to a new level of high precision and increased performance.

Professional Sing Panels are specially reinforced for increased performance by our team of experienced professionals with an acute sense of composite technologies to create a professional panel that will have the structural integrity to far exceed performance standards deemed “acceptable” by the trade industry.

The Professional Sing Panel is available only to trade professionals, includes embedded stiffeners, and is primarily used in oversize door applications.

Professional Non-Warp Door Blanks

Using patented Professional Sing Door Blanks, any door can be made in any style of any material in any size that can be guaranteed to be true flat (well above AIA standards for flatness) and not to warp for 50 years including structure guarantee when used for intended purposes for which the door was designed.

Using patented Professional Sing Door Blanks, any door can be made in any style of any material in any size that can be guaranteed to be true flat (well above AIA standards for flatness) and not to warp for 50 years including structure guarantee when used for intended purposes for which the door was designed.

Custom Professional Sing Panel

Custom Professional Sing Panels are available in any size, any thickness i.e., large oversize panels or planks, posts and beams, with any of the following custom options.

Custom Professional Sing Panel Upgrade Options

Available to trade professionals and industries are a myriad of Sing Panel options that include (but are not limited to):

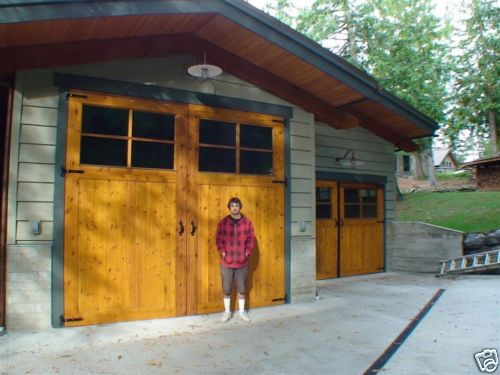

Non-warping Sing Sliding Door in closed position

SKIN CHOICE (SURFACE MATERIAL)

There are many options for Sing Core panels. (See: Material Options)

-

- Paint Grade: 1/4 inch or thicker plywood, MDF, Masonite

-

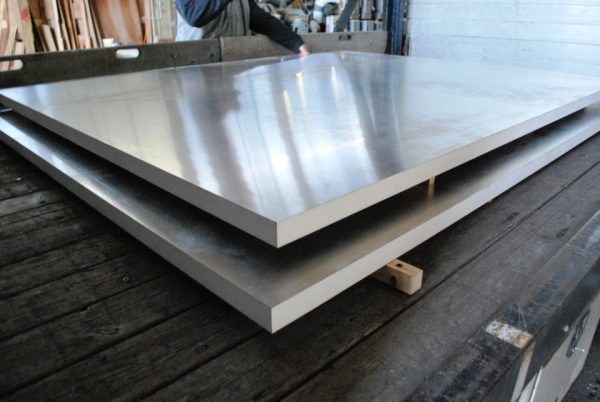

- Metal: 0.20 inch to 0.125 inch aluminum, cold rolled steel, galvanized steel, hot rolled steel

-

- Wood Grain: Thin wood veneer 0.020 inch on top of 0.125 inch MDF over top of a professional Sing panel

-

- Wood Stave: 0.125 inch applied over the top of a professional Sing panel

Non-warping Sing Sliding Door in opened position

And any other options that may be available per your specifications. Contact us for more information.

WINDOW AND DOOR CUTOFFS

Sing Core provides Sing panels with window and door pre-cut and ready for installation. We will cut 1/8 larger in width and 3/16 inch wider in length to fit your window glass. We build a frame using 1.25 inch solid wood to your specifications.

MOLDING/TRIM

Sing Core windows and doors are profile ready for CNC routing. You may add molding or trim to create your own window or door design, otherwise we will provide you with thicker skin – such as 1/4 inch or thicker MDF, hardboard, etc. – for you to carve or profile by CNC machine. With Sing Core windows and doors you can create a true raised-panel door or any design you desire.

Trim added to create a raised panel door

TRIMMED OR UNTRIMMED (RAW EDGES)

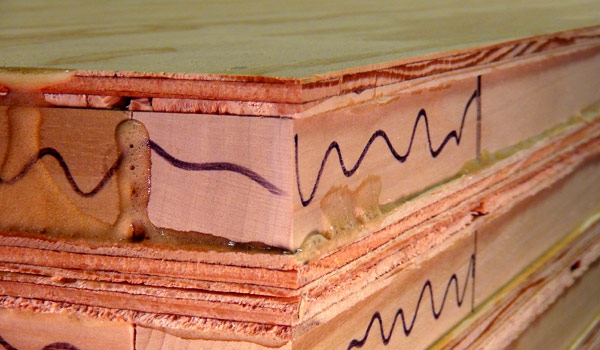

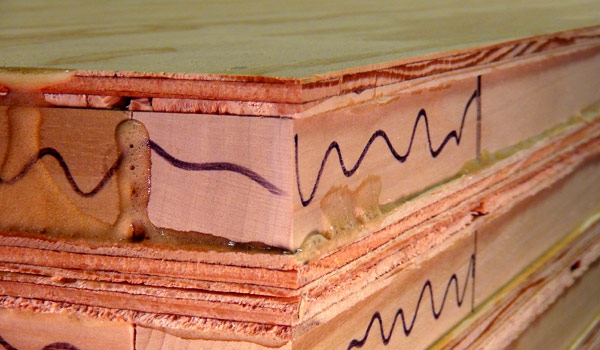

The standard ready-to-ship panel condition is, “untrimmed.” This leaves unfinished exterior edges that may have exposed adhesive and might require being built ½ inch over-sized for trimming at your location. An additional fee will be assessed for trimming and sizing in our factory.

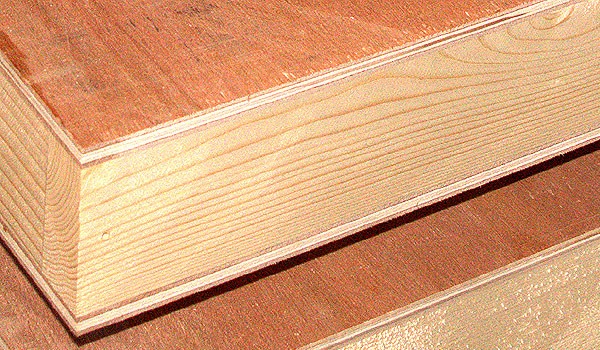

All trimmed edges are 1/2 inch over width and 1/2 inch over length. After trimming, your Sing Panel will be 1/2 inch less (4 x 8 will be 47.5 inch x 95.5 inch). Standard solid wood edging with 1.5 inch will be reduced to 1.25 inch after trimming.

UNTRIMMED PANEL (RAW)

Many of our customers prefer their panels untrimmed because this allows them to trim their panels to exact size on site before installing them in their door openings. That way they can have the peace of mind that their door will fit the opening exactly as intended.

TRIMMED PANEL

Customers who want their panels cut to exact size before they receive them should choose the trimmed selection. This gives them the option of doing less work on site, but it also means they must be much more precise with their measurements before ordering their panels. Trimmed also costs slightly more because it is more labor intensive to trim the panels in house.

BLOCKING FOR HARDWARE

Sing Core panels can be used with any hardware that is rated for the weight of the panel. Solid wood blocking is placed in your specified locations to accommodate your hardware. How to specify your blocking for hardware.

INSULATION VALUE

- R-value 3.5 (EPS foam)

- R-value 5.7 (urethane foam)

WEIGHT

Sing Core panels weigh only 4 to 5 pounds per cubic foot depending on your skin choice.

COMPRESSION STRENGTH

Our 1-inch professional grade panels have been tested to reach 660 psi.

WARRANTY

Sing Products come with a limited lifetime guarantee. (See Warranty Information)

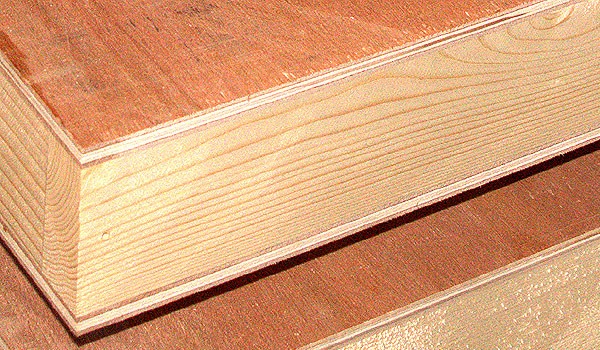

Professional Sing Panels commonly have a solid wood edge (1.25 inch is standard, any custom size is available).

Professional patented Sing Core creates the best non-warp, lightweight, high strength panel material for superior construction with embedded professional stiffeners.

If you are an architect, general contractor or millwork and expect a non-warp guarantee from the door manufacturers (especially the very large and expensive doors) you would be very hard-pressed to come to an adequate warranty arrangement with either a door manufacturer or millwork because large doors and doors made of exotic woods are prone to fail; that is, unless the door is made with Professional Sing Panel inside. This is how we help to make the best doors in the world that can be guaranteed for structure strength and not to warp for 50 years.

In the event one side is exposed to excessive moisture or temperature then it could cause warping if the panel is very thin. If you have high expectations for non warping (which most of the high end large doors have problems with) Professional Sing Panels are the only insulated panels that warp less than any known core material. All Sing customers are happy with what we deliver when using the Professional Sing Panel to build their non-warping doors; which is changing the previously known idea that all the large doors in North America warp due to the change of seasons. The secret inside the best non-warping doors is the Professional Sing Core which keeps the Professional Sing Panel flat from our factory to its destination and stay flat for 50 years with structural integrity guaranteed.

A Professional Sing Panel consists of a substrate of patented Sing Core torsion box reinforced insulated core with special patent pending Sing stiffeners sandwiched between two ¼ inch sheets of plywood, resulting in the most Eco-friendly lightweight and high-strength (660 PSI, stronger than steel pound-for-pound) non-warp material. The Professional Sing Panel is the basis of many applications spanning a multitude of industries.

Sing Core Security Doors

Sing Core Security Doors