Sing Core’s alternative to aluminum honeycomb panel. aluminum honeycomb panel is used as core material in a variety of applications such as facades, walls, floors, ceilings, roofs, inside doors and partitions. Aluminum honeycomb core also found inside workbenches, craft tables, laser cutting tables, and a wide range of other types of work surfaces, especially when there is a desire to reduce the weight of the end product.

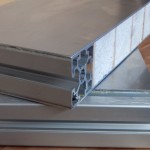

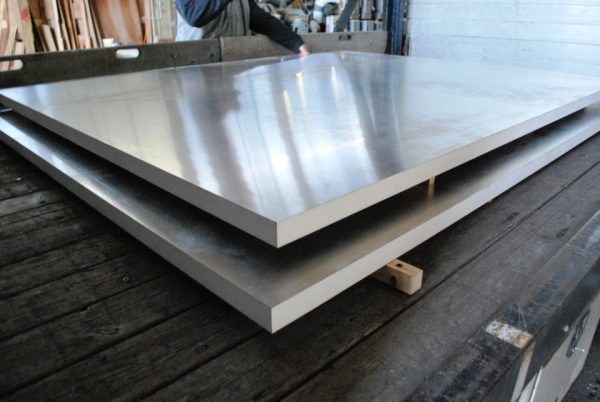

Sing HPL Sandwich Core

Sing HPL Sandwich Core is far superior to any aluminum honeycomb core in the following areas:

1. Strength-to-weight ratio

2. Fully insulated

3 High precision

4. Longevity

5. Eco-friendly

6. Warp-free

7. Low cost

1. Strength to Weight Ratio

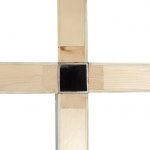

Sing HPL Sandwich Core exceeds all expectations when it comes to strength vs. weight thanks to SingCore’s patented and patent-pending technologies which are the foundation for the success of Sing’s core. Long ago, Sing coined the phrase,

“Heavy does not mean strong, and lightweight doesn’t have to be weak.”

Sing’s invention changed the way architects and engineers brought their creative endeavors and problem-solving solutions to life.

2. Fully Insulated

Sing HPL Sandwich Core is a key ingredient in breach proof impact doors, and other applications where sound proofing, refrigeration, defense, and separation is imperative. Due to the nature and construction of Sing’s HPL Sandwich Core, no effort needs to be made to achieve an acceptable degree of sound deadening or climate control.

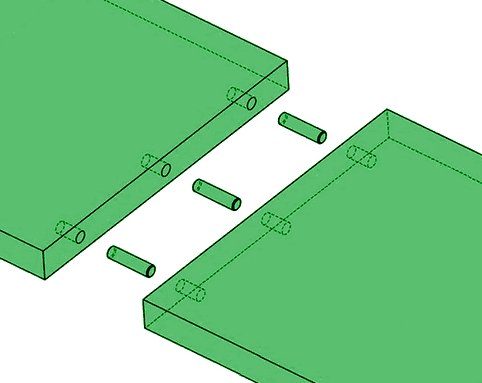

3. High precision

When the attention to detail demands high precision, no core material is more precise or stable than Sing HPL Sandwich Core sporting an impressive .006-inch tolerance. This is why Sing HPL Sandwich Core is hands down the go-to solution for dead flat tables supplied by the best high-end millworks in America today.

4. Longevity

When it comes to composite cores, risk is assumed in the area of the lamination process which holds the various products together over time. Sing’s patented and patent pending technologies eliminate the risk of delamination over the life of the product in use. And even comes with a 50-year structure warranty which includes delamination, so you don’t have to worry about it.

5. Eco-friendly

Aluminum Honeycomb Panels are made offshore and imported for use in the USA. Why? Because the production process is so toxic to the environment that it would be nearly illegal to manufacture in the United States. Even so, we still share the same air and oceans with our neighbors outside our borders. This matters to Peter Sing who only uses USA-sourced and natural materials holding the highest standards for Eco-friendly manufacturing methods for a better world.

6. Warp-free

Sing HPL Sandwich Core is long-renowned as, “the only way” to create large, panelized structure materials that will not warp under strenuous conditions. Though note that Sing’s True Flat Team must be involved in the engineering and manufacturing of the project because many factors must be taken into consideration to create a warp-free product, such as size, skin type, location, and application. Still, the only 50-year warp-free guarantee in the industry, regardless of size.

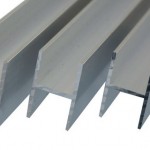

Other Types of Core Materials

Sing HPL Sandwich Core is vastly in the process of becoming the replacement core of choice over other types of lightweight core materials such as paper honeycomb, and different kinds of urethane core, EPS core, wood-based core, such as particleboard, LVL, solid wood core, as well as aluminum honeycomb core to keep the working subject straight, flat, or lightweight over time without fail.

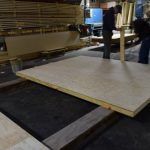

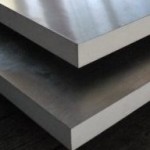

Sing MDF Composite

Going a step beyond the Sing HPL Sandwich Core, one of the most popular hybrid composite products in huge demand is Sing’s MDF Composite available in core or panelized with solid wood edges and implants. This has the embedded HPL for all the high performance results, plus it is topped with a super smooth 1/8” MDF for easy painting or lamination of nearly any material.

Sing Core MDF Composite

This is one very basic, less expensive option, but if you want to be straight, with concern of warping, or telegraphing, would require an upgrade with special skin underlayment beneath the MDF skin on top of Sing Core.

This creates a either a core material or full panel with stable material on both sides with MDF skin for paint grade or cold press purposes. More stable translates to less chance of telegraphing, and designed for high-end precision and smoothness. The price is a little bit over than that of standard MDF-only skin.

But, if you want to do hot press, then you must take advantage of our special hot press process. That means you can accommodate the increased high temperature and high pressure without worrying about any telegraphing. This is the most expensive method for the most demanding clients.