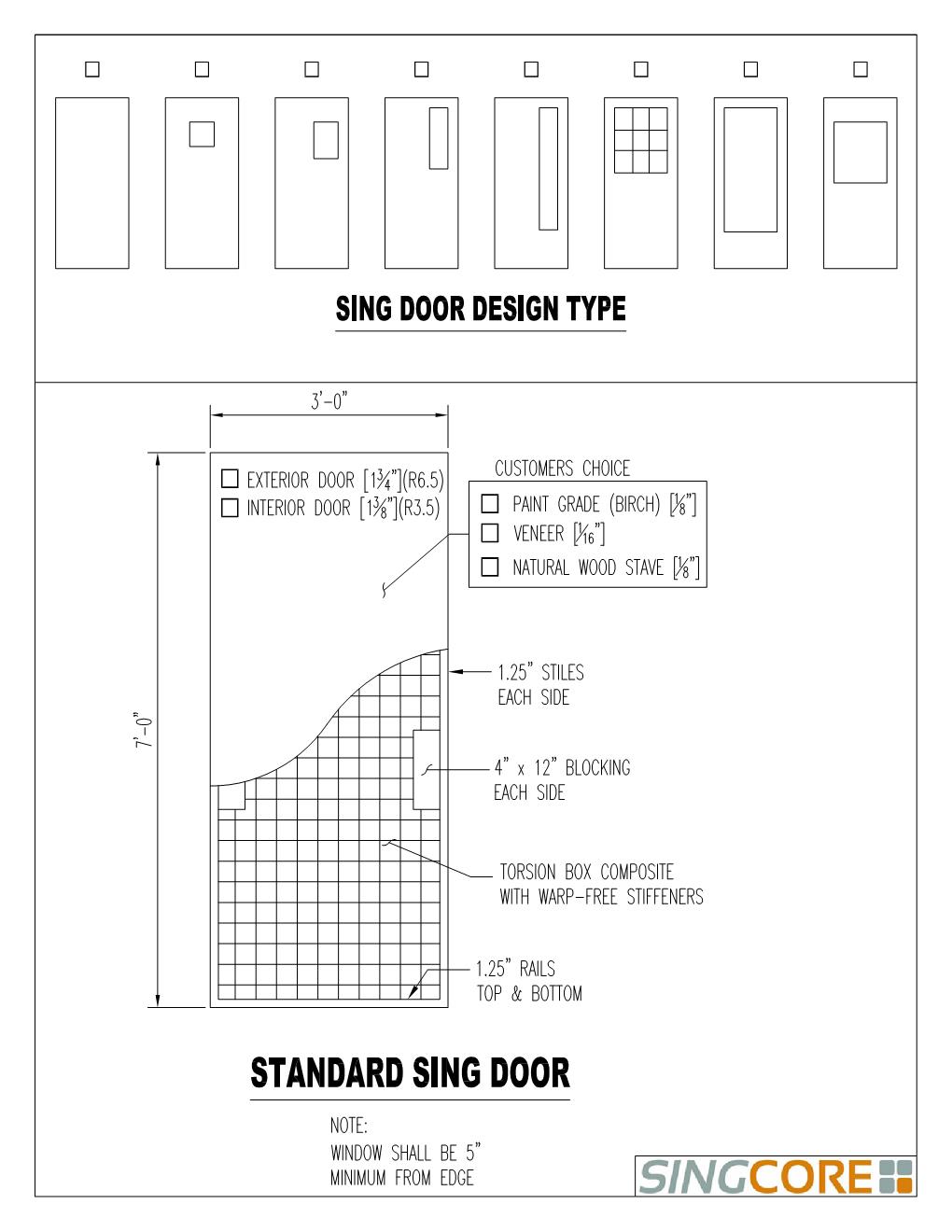

General Specifications

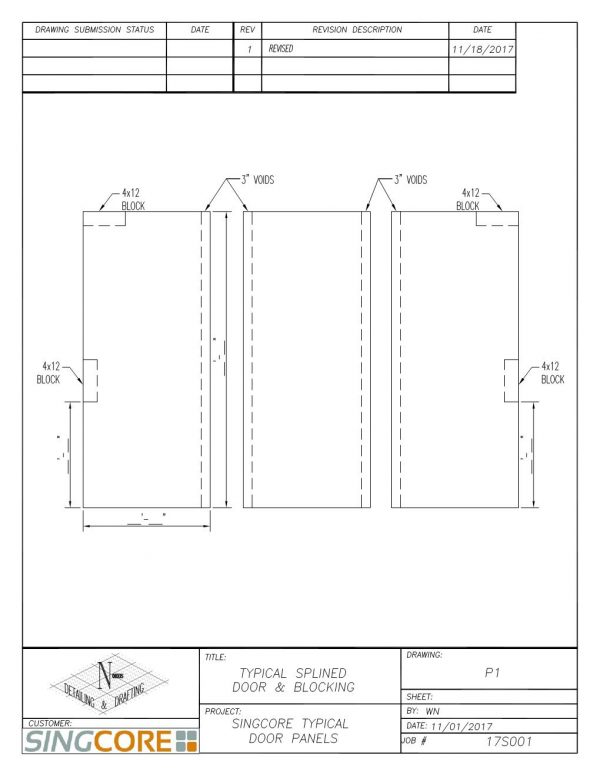

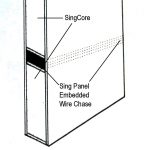

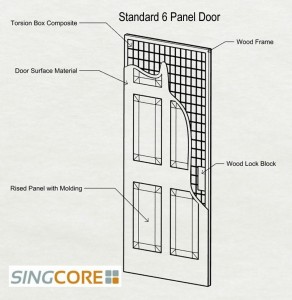

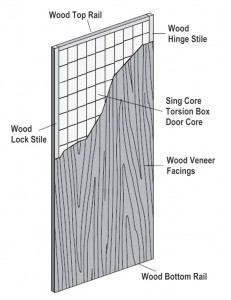

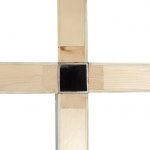

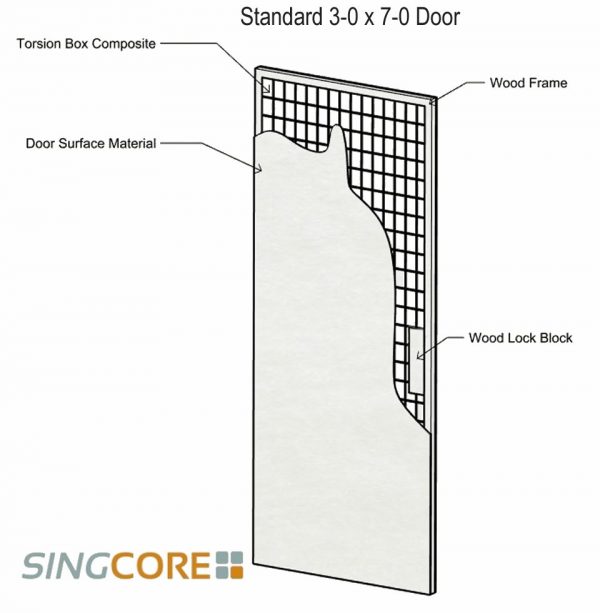

Standard Sing Core 3 0 7 0 doors are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The standard foam material is recycled rigid EPS foam. A 10-inch natural wood lock block is positioned centered at 37 inches for door knob and locking mechanism placement on both sides of the door. The core material is wood framed by 2-inch natural wood for finishing strength and attaching hardware. The torsion box is completed by adhering an exterior surface material (skin) in your choice of paint grade (Birch ply), wood veneer(s), or natural wood stave. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Standard Sing Core 3 0 7 0 doors are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The standard foam material is recycled rigid EPS foam. A 10-inch natural wood lock block is positioned centered at 37 inches for door knob and locking mechanism placement on both sides of the door. The core material is wood framed by 2-inch natural wood for finishing strength and attaching hardware. The torsion box is completed by adhering an exterior surface material (skin) in your choice of paint grade (Birch ply), wood veneer(s), or natural wood stave. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Standard Sing Core 3 0 7 0 Doors include frame perfectly suited for the door of your choice and ready to hang. Specify either 2×4 or 2×6 wall thickness to determine frame size for door installation (not supplied by Sing Core).

Every Sing Core manufactured door is finished to specifications and guaranteed for 5 years for structural integrity.

Detailed Specifications:

Scope: Subject to local building codes, the standard Sing Core door is intended for use in:

- Single family dwelling interior applications

- Multifamily dwelling, low-rise professional office, library and low-rise motel interior applications

- Lighter use industrial building and factory, hotel and retail sales building interior applications

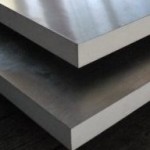

Product Description: Standard 3 0 7 0 door panel manufactured by Sing Core available in 1 3/8” or 1 3/4″ thickness is designed for side-hinges (not supplied).

- Door component includes paint-grade door panel, wood veneer, or wood stave for 2×4 or 2×6 wall installation

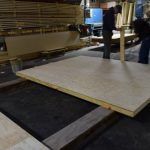

Door Panel Materials: Sing Core standard 3 0 7 0 doors are manufactured using Eco-friendly cold-press process. Composite materials include:

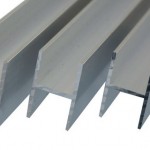

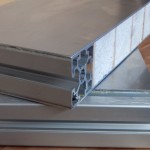

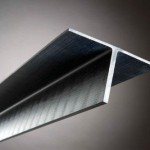

- Sing Core vertical wood-grain torsion substrate filled with recycled EPS foam

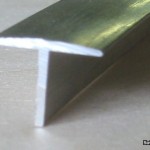

- Core material is framed with 2-inch wood stiles and rails

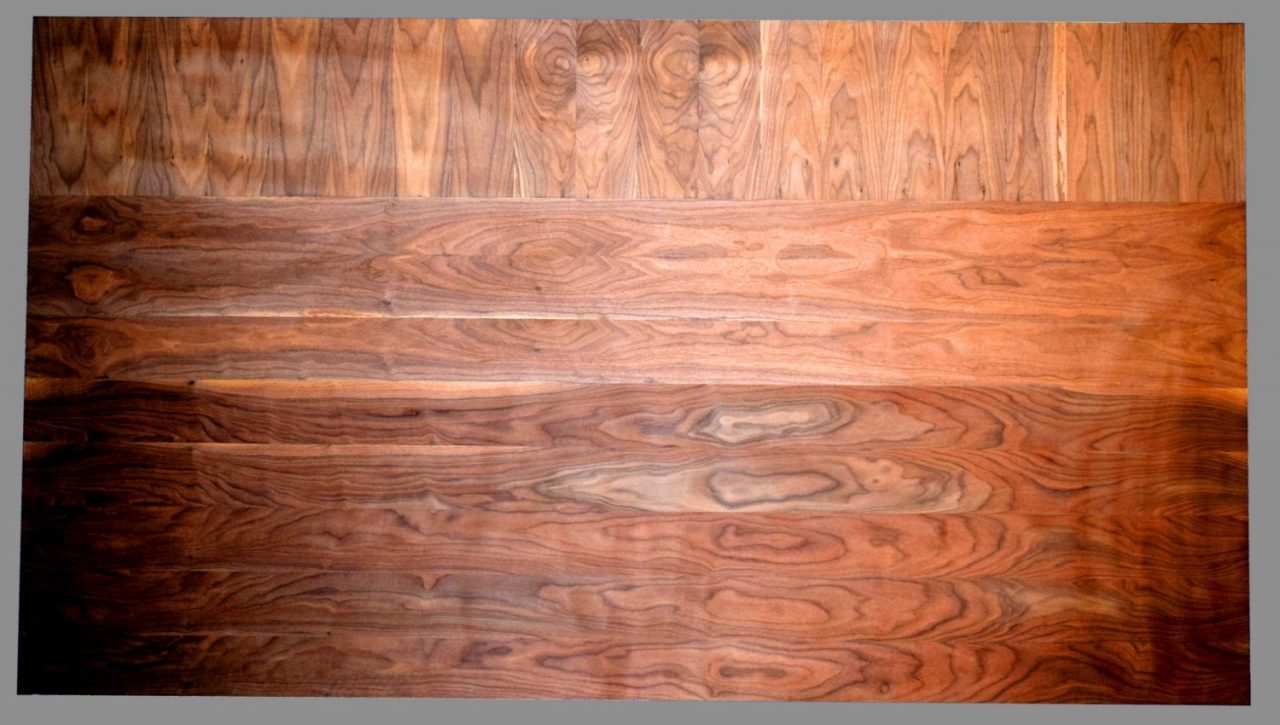

- Facings are your choice of paint grade (Birch ply), wood veneer, or natural wood stave

- Formaldehyde-free bonding agent is used for adhesion of all components

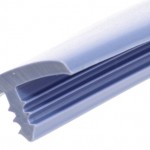

Interior Door: Features R 3.5 per in. insulation, available in 1 3/8″ or 1 3/4″ door thickness.

Exterior Door: Features R 6.5 per in. insulation, available in 1 3/4″ door thickness only

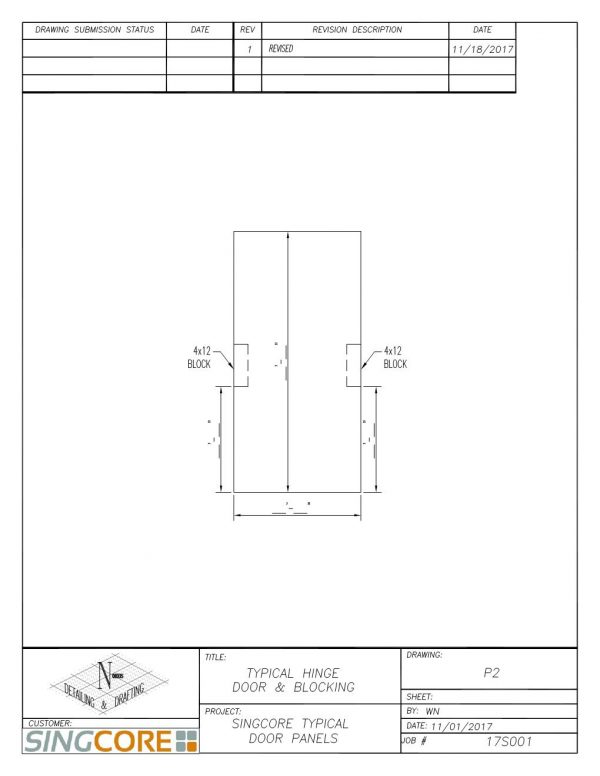

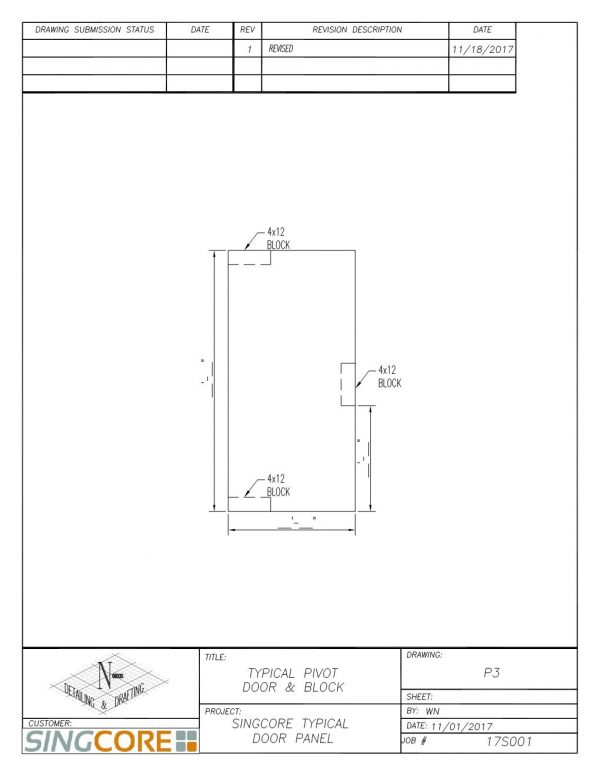

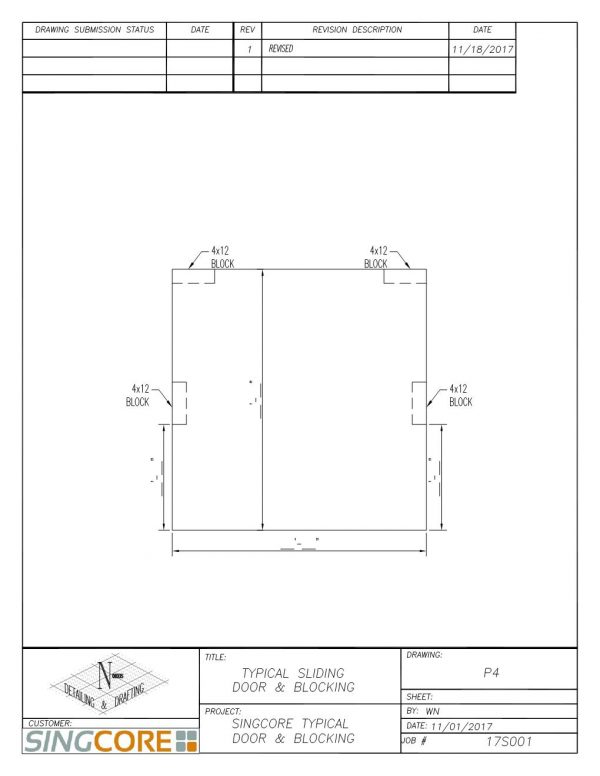

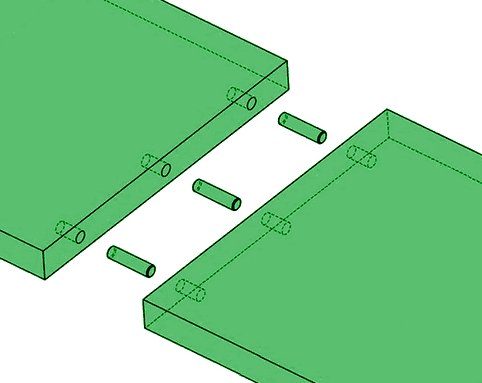

Interior Blocking: Solid wood implant is inserted for door knob and/lock block hard points on both sides of door.

Delivery: Reasonable care is taken to ensure safe transportation of your Sing Core 3 0 7 0 door from factory to door shop for finishing and pick-up or deliver to your location.

Storage and Protection: Store your Sing Core standard 3 0 7 0 door in an upright position and allow to acclimate to room temperature following shipment receipt or prior to finishing or installation.

Preparation: Per manufacturer’s specifications, ensure that door frame openings are constructed plumb, true and level prior to installation. Select fasteners of adequate type, number and quality to assure proper function.

Installation: Installer shall be specialized in the installation of the type of work that is associated with the project and will comply with manufacturer’s installation policies and procedures to ensure proper end use.

- Verify that hinging and latching assemblies operate freely and correctly

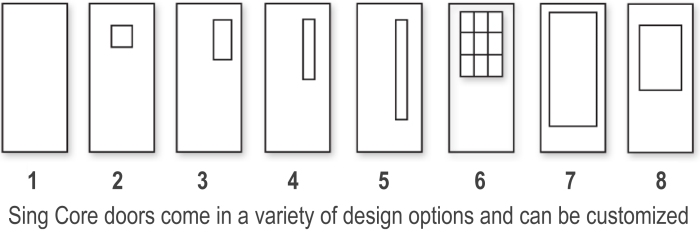

Finishing: The standard finishing and sealing of the Sing Core standard 3 0 7 0 door includes paint grade (Birch ply), wood veneer, or unfinished natural wood stave. Additional finishing options include your specifications at additional charge.

Machining: Sing Core standard 3 0 7 0 doors are easy to work with in the millwork shop for CNC machining or on-site for finishing, sawing, sanding, cutting and fastening. No specialized skills or equipment is necessary, other than standard woodworking tools are necessary. Treat Sing Core doors just like you would any other standard wooden door blank.

Strength Performance: Patented Sing Core has an unsurpassed strength as compared to other lightweight substrate materials tested at 660 PSI (based on 2″ x 2″ grids and 3/4″ thick) for superior structural integrity and is resistant to warp, twist and crack when compared to other materials.

Light Weight Performance: Sing Core weighs much less than other traditional building materials, as much as 50% less; or more, as little as 4 lbs. per sq. ft. yet sustainable and true green technology.

Insulation Performance: Standard Sing Core 3 0 7 0 doors feature built-in insulation value with an R3 rating per inch.

Acoustical Performance: Sing Core standard 3 0 7 0 doors have a natural sound-deadening quality for noise control. Standard sound transmission class (STC) is 30.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste. The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Warranty: Sing Core manufactured doors are structurally guaranteed for 10 years under normal conditions.

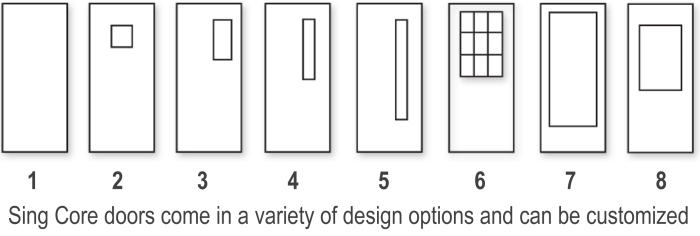

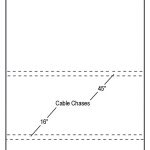

Basic Sing Door Spec Drawings: Click here

See also: Door Technical Information

Appearing regularly in Contemporary Architecture Design

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.