Applications -> Building Components -> Doors -> Architectural Door Specs

General Specifications

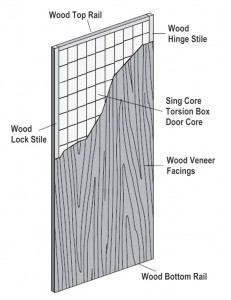

Standard Sing Core doors are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The foam material is available in various forms depending on your specification. The default is recycled EPS foam. Natural wood lock blocks are positioned at locations as necessary for locking mechanism placement or as anchor points. The core material is wood framed by 1.25 “ natural wood. The torsion box is completed by adhering an exterior material (skin) according to your specifications. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Every Sing Core manufactured door is unfinished (unless specified otherwise).

PART 1: GENERAL

1.01 SUMMARY

- This section includes specifications for SingCore professional door slabs, designed to provide a stable and durable solution for door applications.

1.02 RELATED DOCUMENTS

- Drawings and general provisions of the contract, including general and supplementary conditions and Division 01 Specification sections, apply to this section.

1.03 REFERENCES

- ANSI/WDMA I.S. 1A-11 – Industry Standard for Architectural Wood Flush Doors

PART 2: PRODUCTS

2.01 MANUFACTURER

- SingCore

1134 N Summit Rd.

McCleary, WA 98557

2.02 MATERIALS

- SingCore professional door blanks shall consist of patented SingCore technology, utilizing a core material with structural reinforcement that prevents warping, twisting, and bowing.

- Facing material shall be [dependent upon finish]

2.03 SIZES AND THICKNESS

- Door blanks shall be manufactured in various sizes and thicknesses as per project requirements.

PART 3: EXECUTION

3.01 INSTALLATION

- Install SingCore non-warping door blanks in accordance with the manufacturer’s installation guidelines and approved shop drawings.

- Ensure that the door frames and hardware are compatible with SingCore door blanks and are installed to the manufacturer’s specifications.

3.02 FINISHING

- Finish the door blanks in accordance with the manufacturer’s recommendations for the specified face material.

- Apply finish coats evenly and thoroughly to both faces and edges of the door blank to ensure uniform appearance and protection.

- Follow the manufacturer’s guidelines for finishing procedures, including sanding, staining, and sealing.

By following these specifications, the SingCore non-warping door blanks should provide a reliable and durable solution for your project. It’s essential to consult with the manufacturer and adhere to their guidelines for optimal performance.

See also: Door Technical Information

Appearing regularly in Contemporary Architecture Design

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.