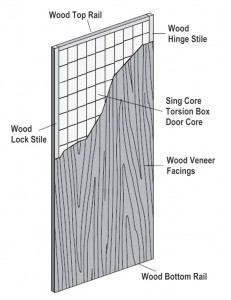

Sing Core’s Eco-Friendly Design

Here at Sing Core, we strive to leave the Earth better than we found it. That philosophy drives our material sourcing, production methods, and many more aspects about how we run as a company.

Eco-Friendly Sourcing

When it comes to our wood, insulation, and other materials, we source them from the most eco-friendly places we can find. For example, the wood we use is renewable, and our insulation isn’t shredded fiberglass. Our panels are crafted to be high quality, long lasting, and strong, but we don’t sacrifice our Earth-conscious promises to achieve that.

Lower Emissions

Another way we keep our impact on the Earth in check is through lowering our emissions through local production. We are an all American company, and every one of our panels are made in Washington State. By staying local and keeping business in the country, we not only promote and help the economy, but also the environment, as we have significantly lower emissions and fuel consumption compared to companies that outsource their production. Shipping product, especially large custom pieces, can be incredibly time consuming and uses a lot of fuel. This fuel burning can harm the atmosphere, and in some cases, spills and damages can dump toxic gas and oil into the delicate ecosystems in the oceans. Sing Core doesn’t contribute to this damage on the planet, as we keep our production local.

No-Burn Factory

Many factories burn trash, chemicals, or other harmful materials in their production process. These places often have smoke columns and plumes of thick, dark smoke to mark where they are. At Sing Core, we don’t burn anything in our panel production. There is nothing in our process that requires burning, melting, or anything of the sort, and as such our impact on the atmosphere is near zero.

Better Product = Less Waste

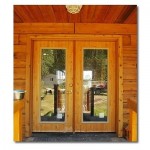

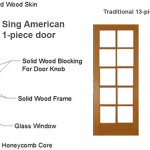

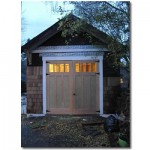

Not to gloat, but Sing Core panels are incredibly strong. Not only that, they last a very long time, and even come with a 50 Year Structural and Warp-Free Guarantee. This may seem like a sales pitch, but it actually plays into our environmentally friendly mission. By creating panels that last a long time and can be easily repaired, we greatly reduce the amount of waste from replacing or scrapping projects. Every time a door needs replaced, it ends up in a landfill, or at best parts of it get recycled. With a Sing Core panel, you won’t have to worry about replacing the door any time soon, which in turn cuts down on our impact on the environment.

Sing Core strives for many things, such as creating the best door and wall panels on the market. But in these endeavors, we will never lose sight of the importance of being eco-friendly. We are also always looking for ways to lessen our impact even more, and are working to join the list of companies that can proudly say they’ve made a difference.