Due to being the newly invented and possibly the most significant improvement in building materials in the last century, it is not uncommon to see Sing products recommended as substitutes for products in the original specifications initially specified by architects. Even though Sing Core is new, we are not that new and have years of experience to assure or most demanding clients that they only deliver the best to their clients.

Why would you substitute Sing Core?

Eco-friendly

In this day and age, it is of primary importance to take into consideration that the impact of your project will have on the earth. Everything we do to help preserve our precious planet is a step toward providing a better world for all life for generations to come. Sing Core’s true green technology is a huge step toward responsible sustainability.

In this day and age, it is of primary importance to take into consideration that the impact of your project will have on the earth. Everything we do to help preserve our precious planet is a step toward providing a better world for all life for generations to come. Sing Core’s true green technology is a huge step toward responsible sustainability.

Lightweight

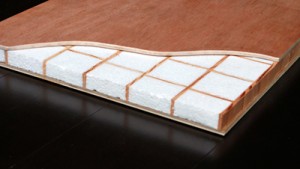

One of important advantages of sing Core is its lightweightedness when compared to other building products. Other traditional building components that can even come close to matching the lightweight characteristics of Sing Core are extremely weak and have little or no structural integrity. This might be acceptable for visual representation upon installation, but may deteriorate rapidly over time, something that you might need to consider in the design process.

Extremely High Strength

Sing Core is super strong, so strong, in fact, that independently tested results from the University of Washington revealed a PSI of 660-to-over-1,100 pounds per square inch of compression strength, which is stronger than steel pound for pound. This is why you see Sing Core substituted in extreme weather, under heavy loads, maintain strength over long spans, blast and bullet proof applications.

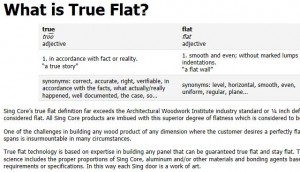

True Flat

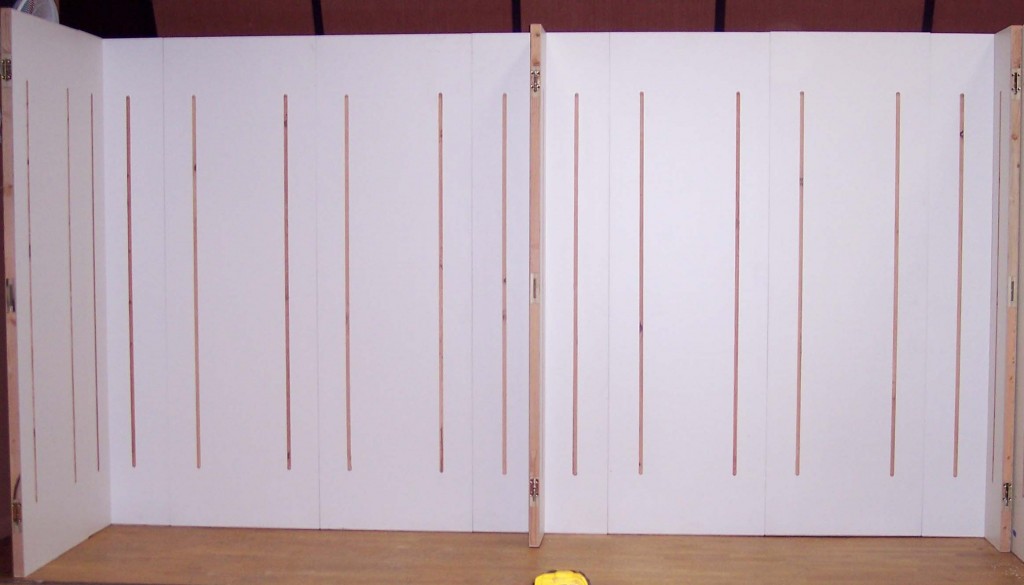

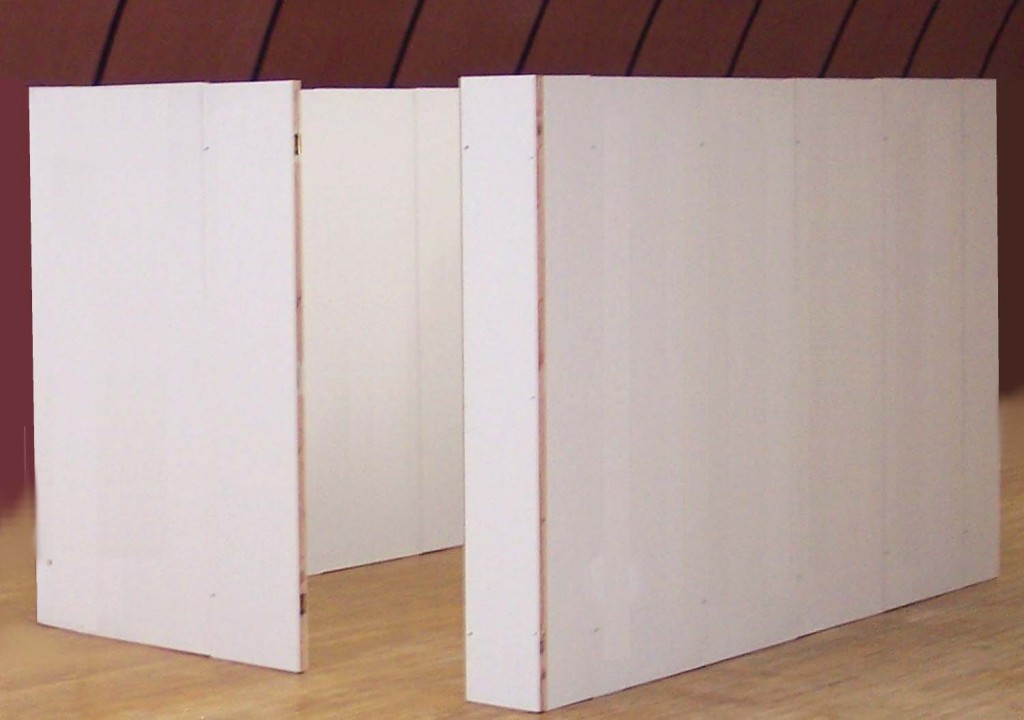

Prior to the invention of Sing Core it was nearly impossible – or extremely expensive and laborious – to build a true flat door (or any other surface desired to be flat over a long span with little or no framing). In fact, current regulations for flatness allow for a ¼” of deflection over a 6 foot span. Sing Core outperforms any other material and can be combined with wood and other products and still be guaranteed true flat.

Prior to the invention of Sing Core it was nearly impossible – or extremely expensive and laborious – to build a true flat door (or any other surface desired to be flat over a long span with little or no framing). In fact, current regulations for flatness allow for a ¼” of deflection over a 6 foot span. Sing Core outperforms any other material and can be combined with wood and other products and still be guaranteed true flat.

Inexpensive

You might be surprised that a building material that is made in the USA cost much less than other composite materials and is so affordable, that it is not priced much more than particle board and can end up being much more inexpensive especially when you factor-in savings in shipping, handling, installation and maintenance costs.

Guaranteed for Life

Sing Core is such a structurally sound building material that it is possibly the only material that can be guaranteed for life, but is designed and built to last for centuries, with little or no deterioration over time, when product is used as specified. When product is properly matched to application, sing Core will not warp, bend, twist or rot, like other materials.

And that only comprises the top half-dozen reasons that people are switching to Sing Core.

As the project owner, you may have just found us on the Internet and want to see Sing Core featured in your project due to all the added benefits. We work hand-in-hand with designers, architects, contractors and homeowners to make sure that you have the right Sing products to match your requirements and specifications. This makes the job safer and more efficient for your general contractor and your architect will thank you for being diligent and for introducing them to Sing Core which they will continue to include in future designs.

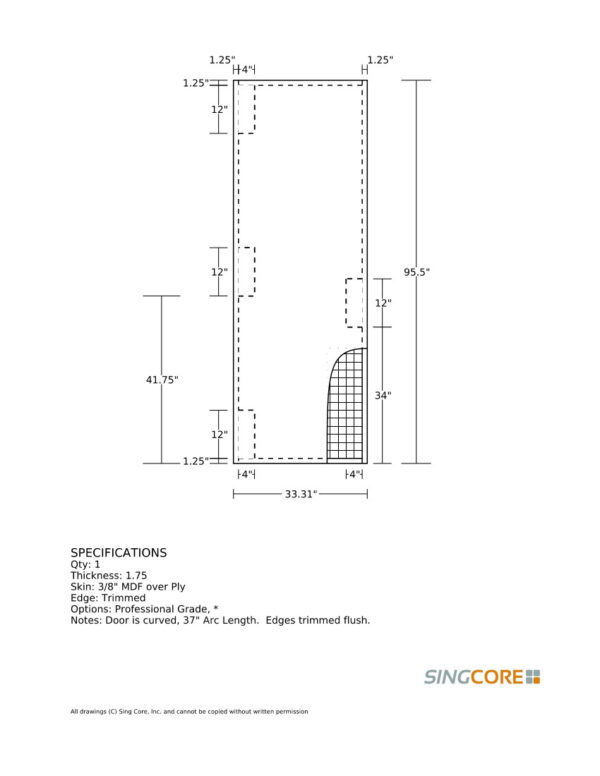

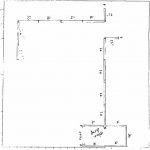

How to Specify Sing Core Inside Your Doors

When specifying Sing Core inside your doors, you can specify “Sing Core” as the manufacturer but note that the doors will need to be finished by a millwork or custom door manufacturer. This about how this might impact the price (important for contractor during price estimations). It would also be helpful to also specify weight ratio of “3 to 4 pounds per square foot” and “50 year warp-free guarantee,” to prevent substitution by the contractor. You don’t want your client to end up with a substituted non-Sing door and be unaware of it until it warps later (see example).

Does Your Door Have Sing Core Inside?

If your door has Sing Core inside it can come with a full 50-year warp-free guarantee. No other door can be guaranteed like that, unless it has Sing Core inside.

It is rare, but there have been occasions when a door has warped, when someone thought it had Sing Core inside, but it did not.

For instance, last year, an architect in Florida specified a large wooden door with Sing Core inside. The contractor contacted Sing Core and received an initial price quote.

Nine months later, we received a call from the architect who had been contacted by the building department that reported that a large wooden door with Sing Core inside had warped.

We searched our records and could not find any record of the job. We did discover the initial price quote request from the contractor who must have found a different way to make the large door.

Your large door with Sing Core inside comes with a certificate of authenticity and guarantee.

Be forewarned, if your large wooden door doesn’t have Sing Core inside, you can expect it to warp.

Make sure your large doors have Sing Core inside.

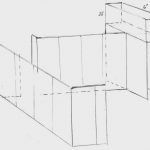

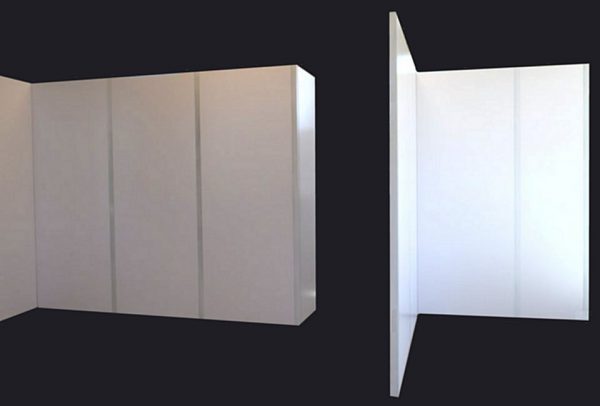

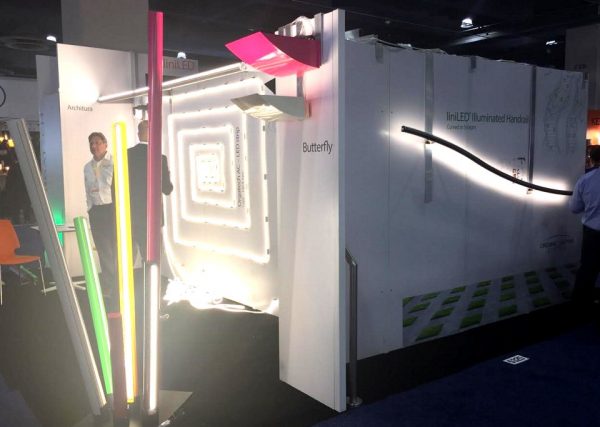

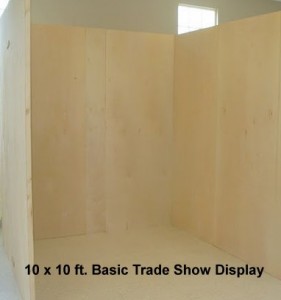

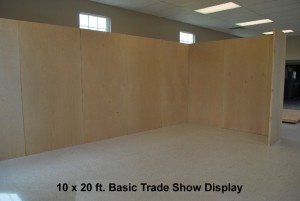

Not Just for Doors

Certainly, we are best known for our door applications, and for many years, people thought of us as a door company because of how superior this material is in that specific application. While we have established ourselves as the perfect door builders – especially when addressing challenging door specifications for oversize, sliding or hinged applications – Sing Core has nearly limitless applications and is featured in many of the most high-end homes. We are the only door that can be guaranteed even after being exposed to weather conditions and no other wood door can be guaranteed true flat.

Certainly, we are best known for our door applications, and for many years, people thought of us as a door company because of how superior this material is in that specific application. While we have established ourselves as the perfect door builders – especially when addressing challenging door specifications for oversize, sliding or hinged applications – Sing Core has nearly limitless applications and is featured in many of the most high-end homes. We are the only door that can be guaranteed even after being exposed to weather conditions and no other wood door can be guaranteed true flat.

Rarely does a day go by where we don’t see someone versed in contemporary architecture design who reaches out to Sing Core to solve another issue of strength vs. weight, saving economically by reducing shipping, handling, installation, repair and maintenance costs, and upgrading the overall green value of a project.

If you have just discovered Sing Core, it is not too late to substitute sing products for the traditional products that were originally specified by your architect. We work with architects and designers to make sure that you have the right sing product to match your specifications, meeting (or exceeding) any expectations that you might have.

We can help you with the substitution submittal process and we have staff on-hand with the experience to make sure that your needs are met or exceeded, and the results can be guaranteed for life (per warranty certificate accompanying your guaranteed Sing product).

If you are like many of our users, you will find that once you discover Sing Core, you will start finding solutions to your dreams and ideas that may have been limited by available building materials of the past.

Join the revolution and see our clients list to see some of the most successful business staying on the leading edge of building technologies by embracing the Sing Core advantage.

.png/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:1280)