It is not uncommon for a contractor on a high-end project to come across a specification for Sing Core that they have not previously seen.

The contractor contacts Sing Core for more information about this particular job.

Congratulations

If you are a contractor working on a project that features Sing Core in the specs, you are privileged and must be considered one of the best contractors in your area because Sing Core is never featured in any project that isn’t considered by architects and designers to be the top in the industry.

You will be expected to be at the top of your game on this project, so congratulations to you for being awarded this project.

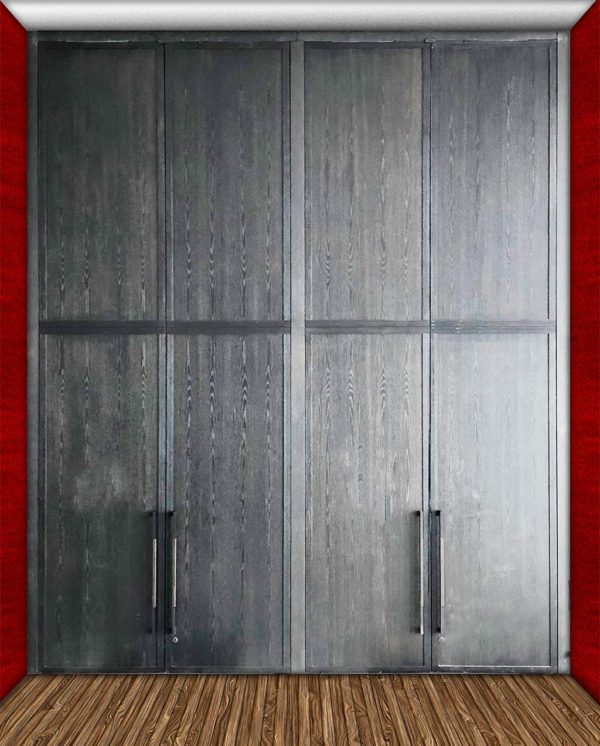

Though shipped all over the world for many different applications, most of the products Sing Core helps to produce would fit this description.

What Next?

Know that working on such a high-profile or top-secret job like this must be handled properly, contacting Sing Core is your first order of business if you find this in your specifications.

Though we are primarily specified for the largest most important doors in America and around the world, Sing Core does not build the enormous doors for which they are so well-renowned.

What Sing Core Does |

|

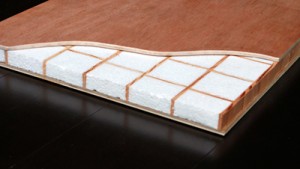

Inventor Peter Sing developed the patent and patent-pending technologies that allow large doors to be built without fear of failure in the very near future. Large doors, especially large wooden doors, have been problematic ever since architects and engineers began to create them, that is until the advent of Sing’s core. It enabled door engineers, manufacturers, and millworks to create enormous fail-free doors that could withstand the text of time.

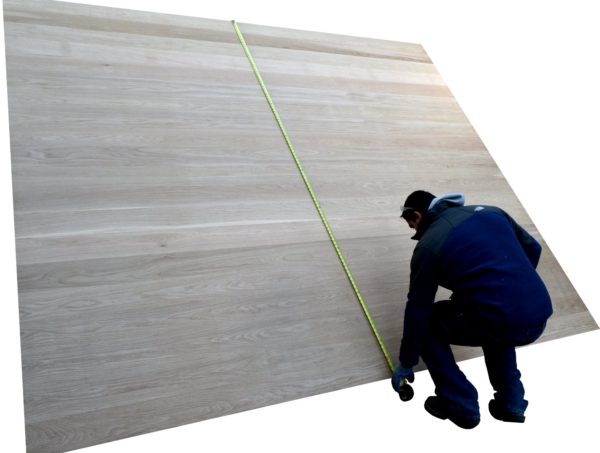

When you contact Sing Core about the door or doors in your specifications, they begin reviewing and designing the interior of the door, the core, to support the surface material of the door so that it will counteract any potential for door warping, which is the main reason why large composite doors fail, especially if they feature a surface material that tends to move, such as natural wood grain.

Then, Sing Core coordinates with the team that will complete the door build. Surprisingly,

Sing Core Does Not Build Doors

They design the base material, conducted by Sing’s True Flat Team, that takes into account all the details of the build and creates the flawless substrate. Then Sing Core coordinates the rest of the process from attaching the surface materials and finishing the door. The door can then be sent to your millwork or door company, who can prep the door, install the necessary hardware, and ready it for installation.

When the specs callout a Sing Core door, it is not unlike Boeing’s 787 Dreamliner specifying a Rolls Royce engine. In the same way as you will see Rolls Royce specified in 35 different types of modern aircraft, you will find Sing Core inside a wide variety of doors around the world.

Contractor’s Millwork

As a contractor, if you work with a local millwork, they may have the proficiency to participate in this extreme door project. If so, Sing Core will work with them and send the unfinished door to them for finishing. You must have a great deal of confidence in your local millwork to trust them to handle such a job.

Utilizing only the best people in the industry on this elite project is of paramount importance to ensure your client’s satisfaction.

Why Architects Trust Sing Core

Architects, engineers, millworks, and door companies trust Sing Core because they understand the science behind Sing’s invention and know that “This is the only way to build such a door,” that will not fail.

Inventor Peter Sing backs all his big doors with his comprehensive

50-Year Warp-free Guarantee

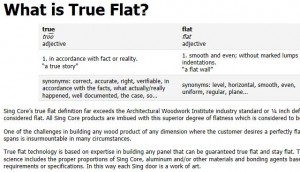

Only Sing Core can create a fail-free large door core that can counteract any surfaces tendency to move without having to sacrifice precision or weight. Sing’s core boasts +/- 006 in. tolerances and weighs in at a fraction of other wood-based door cores. So, your big door doesn’t have to be so heavy that it compromises the structure or is dangerous to handle.

This ensures years of low maintenance enjoyment, which has put many door companies back in the business of creating large, oversized doors, something they had abandoned long ago because they wanted to cover all the doors in a project with their standard one-year guarantee, now these huge doors have an even better guarantee that their standard-sized doors because they have Sing Core inside.

Is a Sing Door Expensive?

Yes, Sing Core is more expensive to use than other door cores, and all the artists and craftspeople who help to create such a one-of-a-king piece of art, all contributing does make these doors more expensive that the average door, but your clients, the ones who have hired you and specified Sing Core on this project will settle for nothing more than the very best, at any cost.

And it’s up to you to see this project through to fruition.