Sing Core is honored to be part of making an innovative workspace for Laserfiche in Long Beach, CA.

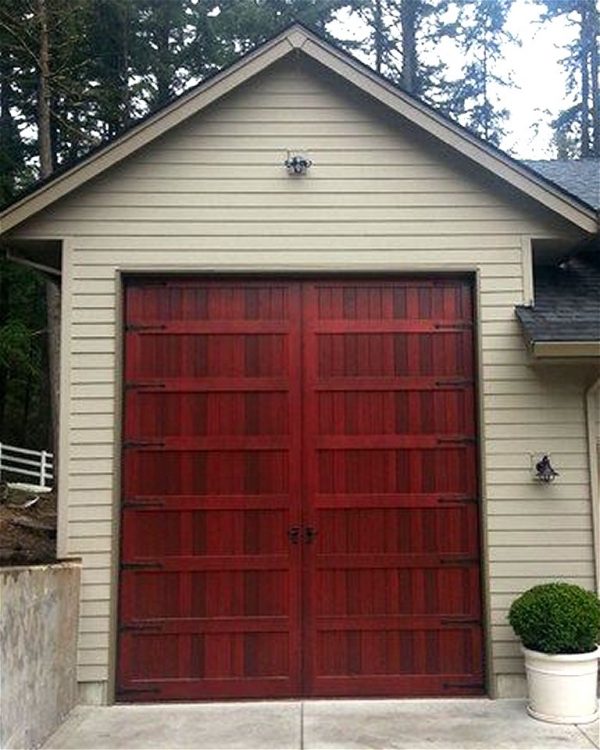

RDC of Long Beach California designed these doors to work seamlessly with this interior workspace. Following the design of RMC, Seeley Brothers Millwork of Brea California used four custom made Sing Core panels to complete this project for Laserfiche.

These Sing Core sliding doors are used to allow these workspaces to feel like one larger room and a second later be a quiet and private meeting space. Sing Core doors naturally dampen noise of an active workspace to easily allow other employees to concentrate and be more productive. These were some of the core ideas that Laserfiche had when building their new Headquarters.

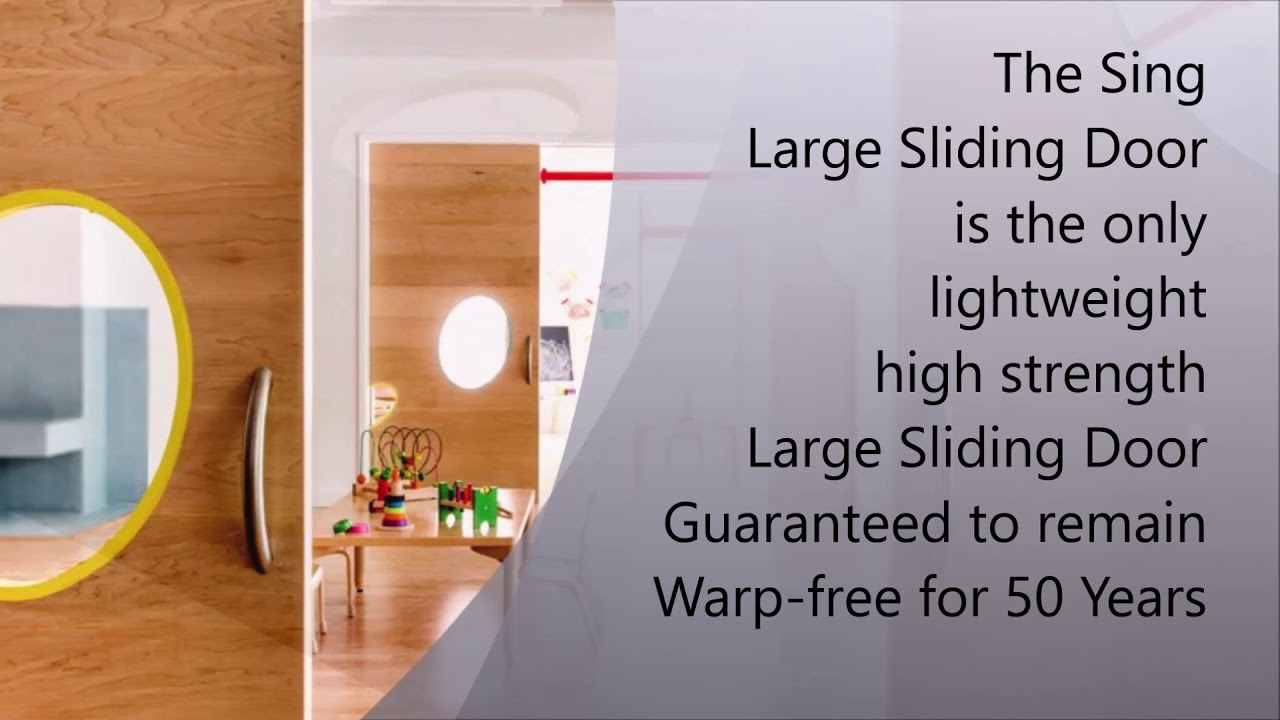

These elegant lightweight doors are extremely strong and durable. They are made of the highest quality material suitable for any museum, mansion or workspace.

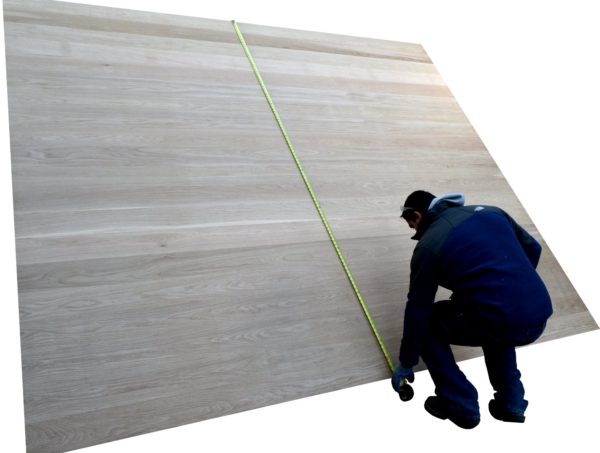

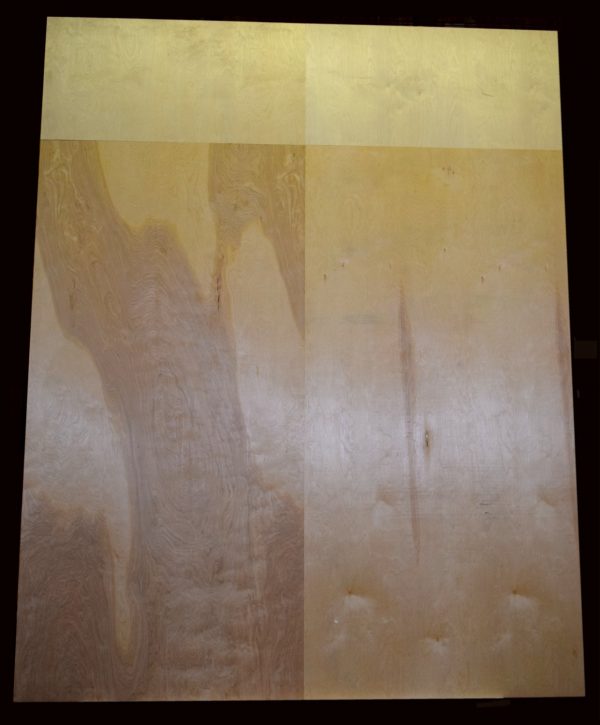

As you can see these doors have to be completely straight to allow a perfectly matched seam when they are closed.

Simple to design, simple to order. See the shop drawings here.

See other sliding doors here.

Want these doors in your next projects? Get an estimate here.

We’d like to thank everyone that came together to make these magnificent doors come to fruition: Studio One Eleven, RDC Architects, Millie and Severson Contractor, Seeley Brothers Millwork and of course Laserfiche for wanting to improve their employee’s wellbeing with this innovated design.

Laserfiche is a leading global prover of business process and information management software. They have been part of the Long Beach community since 2001. They were founded over 45 years ago and also have offices in Washington DC, Guadalajara, Hong Kong, London, Shanghai and Toronto. 320 of the 425 employees are in the Long Beach area and they are steadily growing.

Their new headquarters was completed in May of 2022. It is over 100,000 square feet, with four floors and a parking garage. It can accommodate 550 full-time employees working in-office and up to 750 hybrid workers. Studio One Eleven’s design mirrors a landmark garden-office building across the street designed by the late Mid-Century architect Edward Killingsworth. They incorporated such Mid-Century Modern elements as large windows and terrace decks that provide amble natural lighting. The height is the same as the adjacent building allowing to blend in seamlessly. Chris Wacker, chief executive of Laserfiche, Wacker called the space “extremely functional and useful in a hybrid environment.”

The design layout shifted the service core to the western edge of the building, typically in the center. This allows a larger continuous communal and workspace environment. This also blocks the western solar heat. Now the elevator is tucked away and the stairs are front and center, promoting the healthier option of taking the stairs.

Laserfiche was committed to staying in the Long Beach area and are in the Bixby Knolls neighborhood. Here on Long Beach Boulevard near the San Diego Freeway, their Mid-Century landmark makes a bold statement to the half a million daily drivers who pass by. Before Laserfiche purchased this land, it was considered an unusable wasteland left over from oil extraction years. They capped off the old oil wells and removed the old hazardous tanks.

According to Chris Wacker, Laserfiche CEO, “We have abandoned the traditional vertical office building paradigm, emblematic of individual aspiration, for a horizontal environment where connections are fostered and relationships built and we’ve implemented ideas from our products into the design of the building we know that process automation makes life easier. It removes the bottlenecks and impediments to fluid operations, promotes efficiency and allows organization to thrive. This building’s open design does the same thing. It enhances the free-flowing information making our lives simpler and more creative.”

“This building is the future of work. People sharing spaces in the ways most productive for them. As we learned over the past two years, that makes the most productive for the company and the people that use our products. Just as Laserfiche is dedicated to helping people turn their data into digital assets, this building helps Laserfiche maximize the potential of its people. Laserfiche digital transformation increases your people power by eliminating the unproductive and focusing on the creative, and that’s what this building does. It’s a hybrid workspace for a hybrid workforce.”

Watch this video for a deeper look into this project from RDC.

Sing Core is proud to be a part of the continued evolution of door technology to make our customers’ lives more enjoyable. Whether that be in pivot doors, sliding doors, hinge doors, pocket doors, or any oversize door. We enjoy the challenge. We invite you to GET AN ESTIMATE and see for yourself how Sing Core’s true flat door cores can help you make the doors that your customers are asking for.

Thank you RDC and Studio One Eleven for the use of your photos and video.