People often come to us and ask, “How can you make the best sliding doors in the world?”

The answer is as simple as, “Anyone can make the best sliding door in the world, if you start with the best door core in the world.”

With Sing Door Core at the heart of your sliding door, you start with the best component to build your sliding doors.

You will find that this new patented technology is more affordable than other traditional building materials that you may be using now. View our online comparison and see our new C Series line of Affordable Barn Door and Sliding Closet Doors.

We have discovered – that if you’re like our most discriminating sliding door clients – what attributes you desire in your sliding door. If so, here’s what you want:

I want a sliding door that is lightweight.

One of the reasons that sliding doors fail is due to the fact that they are too heavy for the hardware to adequately handle the stress of slinging a sliding door back and forth over time. Another issue with weight (especially for large sliding doors) is strain on the structure itself, which could compromise the home or building that hosts your sliding door.

I want a sliding door that is strong.

Many sliding doors that are regularly available via retail outlets may be lightweight, but if they are, usually cannot take much abuse. That’s why house rental agencies are constantly replacing sliding doors in-between renters. It doesn’t take much to damage a standard sliding door, and if they could be repaired it would be cost-prohibitive but you could never repair that sliding door to achieve its original strength.

I want a sliding door that will last.

Unless you like to replace your sliding doors periodically, why should you? If your sliding door was built like any other sliding door, then it will likely bend, warp or twist over time. Especially if you have twin sliding doors; you want your sliding doors to be straight and true for the long haul.

I want my sliding doors to provide some privacy.

Most people who have had experience with run of the mill sliding door don’t expect much in the way of privacy. When sliding door customers are looking for sound-deadening sliding doors, they find Sing Core for a variety of applications, including sound proof sliding doors.

I want a sliding door that is not going to let the heat out.

Energy savers know that in most cases, a sliding door is the weakest point of energy loss. Sing sliding doors are packed with insulation to keep the environments on either side of the sliding door uncompromised.

Is there such a thing as an Eco-friendly sliding door?

Yes, in this day and age, planet conscious individuals are seeking out ecologically responsible components and Sing sliding doors are the only affordable Eco-friendly, lightweight high-strength insulated doors that are designed to last for years without compromise.

We humbly agree with our high-end clientele that we do help build the best sliding doors in the world. Only sliding doors built with Sing Core are Eco-friendly, lightweight, strong, insulated, and designed to last for lifetimes, yet extremely affordable compared to other high-tech composite materials that just do not deliver the goods when it comes to high end sliding doors.

Sliding Door Gallery

Check out our gallery of sliding doors we have made in the past. Durable and reliable for all your needs.

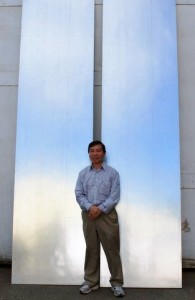

- oversize lightweight high strength honeycomb door

- large oversize lightweight high strength sing sandwich door

- lightweight high strength large honeycomb door

It’s so easy to use Sing Panels to make beautiful

It’s so easy to use Sing Panels to make beautiful