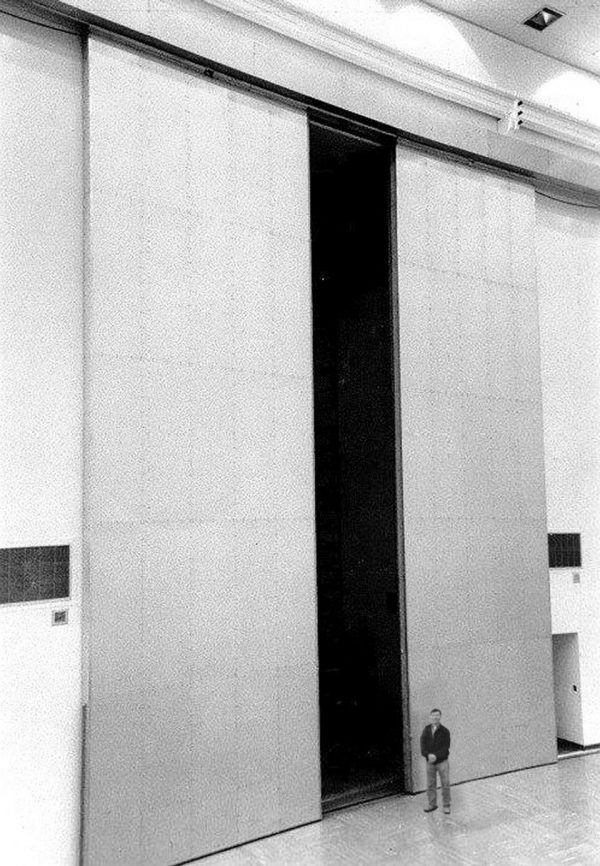

Welcome to the world of big sliding doors, where we bring all your biggest sliding door dreams to life and guarantee worry-free enjoyment of your warp-free big sliding doors for 50 years.

Thanks to the patented and patent-pending technologies provided by inventor, Peter Sing, for the first time, you can enjoy the biggest sliding doors of all without all the headaches and problems associated with large, oversized doors.

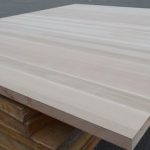

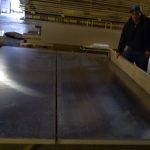

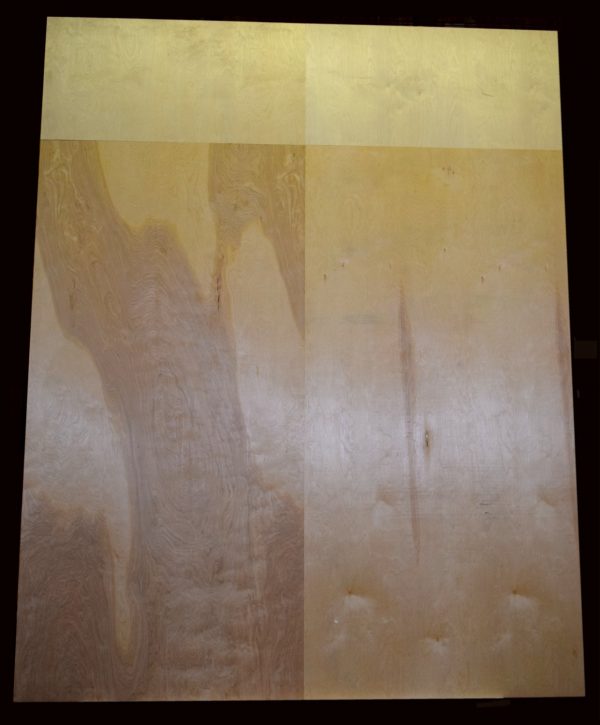

Sing’s door core allows the warp-free door factory located in Washington State to build the most Eco-friendly, lightweight and super-strong big sliding door which will not warp, and as you know, heavy doors that add wear and tear to the structure and hardware, as well as door warping are the biggest challenges associated with big sliding doors.

So, what kind of big sliding door do you have in mind?

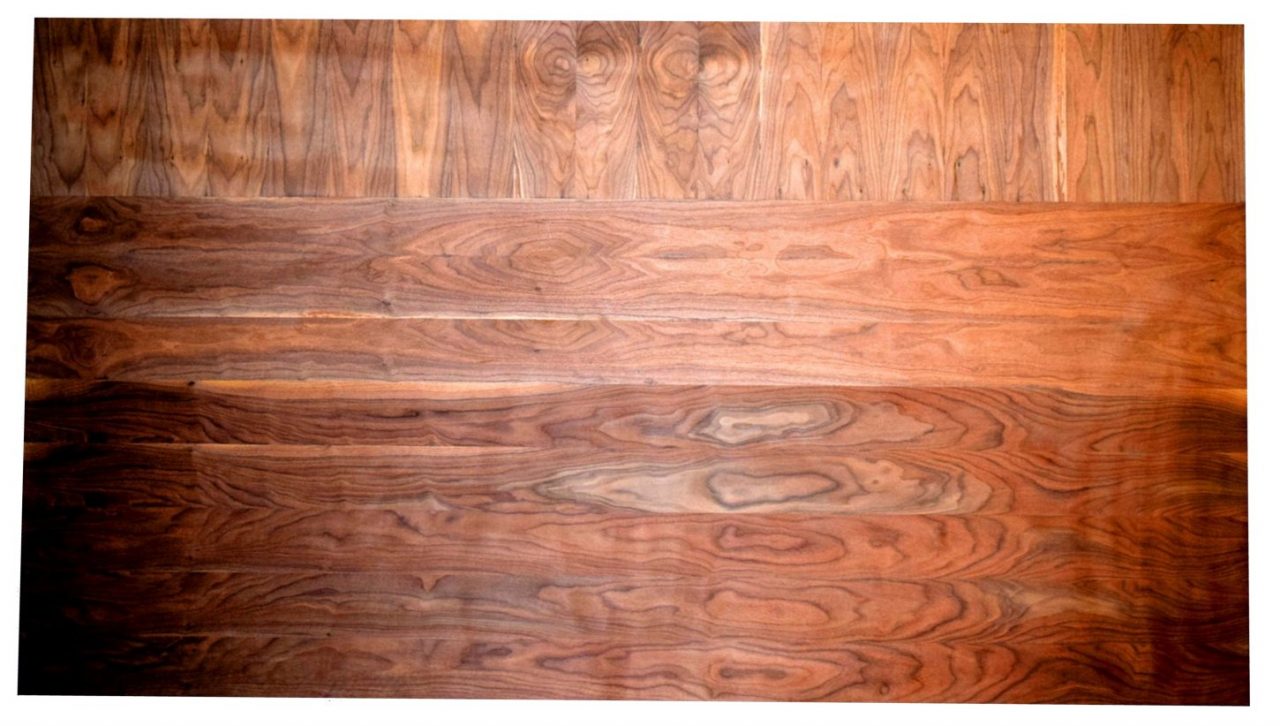

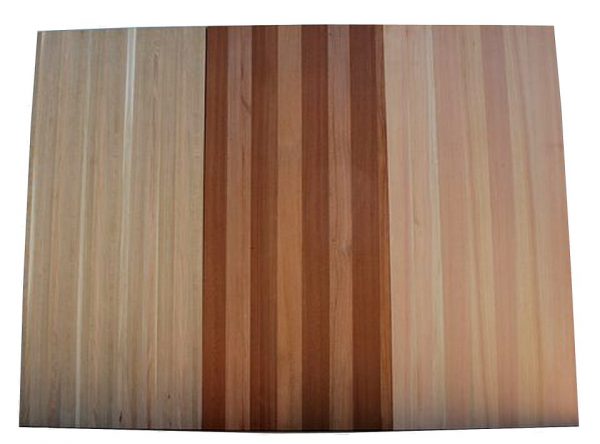

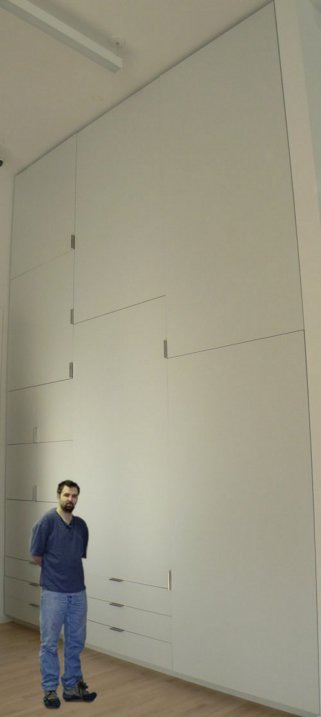

Our most popular big doors are wooden sliding doors. They might not be the most popular sliding doors in the world, but here, at Sing Core, the wooden large sliding door is in the most demand. Why? Because natural wood is notorious for moving according to changes in the environment.

And in most cases, the bigger the sliding door, the bigger the problems you will have with that particular door over time. It’s just the nature of the business, and specifically natural wood, is by far the most beautiful but impractical. That is, until the invention of Sing Core.

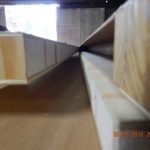

Sing’s True Flat Team helps to engineer or re-engineer big sliding doors to adhere to high performance standards which are unheard of in the industry. Sing’s core is the highest precision (+/- .006 in. tolerance) and highest strength (660+ PSI) lightweight and Eco-friendly large sliding door core in the world. This in combination with Sing’s anti-warp stiffening technologies can help to create a big door that can be guaranteed not to warp, bend, twist, cup, or otherwise fail for 50 years, regardless of the material it is made of.

Of course, Sing’s proprietary anti-warp science is unique to his reinforced vertical grain torsion box hybrid core and unique integration of warp-reversing technology, and the results are not duplicatable outside his factories which are primarily located in Washington State, in the Pacific Northwest.

Most of Sing’s clientele admits,

“There’s just no other way to do it, without Sing Core.”

How else could you make a lightweight failure-proof huge moving wall system with enormous gliding doors or large operable wall systems with big sliding door panels made of wood that are fully insulated, stronger than steel pound for pound, and warp-free, even if one side is fully exposed to the weather? Impossible. That is, unless you have such a system engineered and built with Sing’s core inside.

According to Sing,

We Can Make Any Style of Door

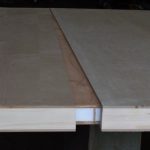

Now, this is an interesting concept. One that is used in high security impact resistant doors with Sing Core inside. For instance, Sing’s True Flat Team, helps to design large modern sliding doors that look like they are built with traditional style and rail door technology. The truth is, the door base is solid composite patented Sing Core, where the door skins are applied in pieces to duplicate the look and feel of stile and rail design.

If you were to kick a stile and rail door at the seam, the door would cave in. Sing says, “If you kick my door, you break your leg,” not Sing’s door.

Plus, the added insulation offers both sound deadening and climate control capabilities to your big sliding door that you would be hard-pressed to find any other way.

So, whether you’re looking for expanding your scenic access to the outdoors with large sliding glass doors, big patio doors, which would be like a wall of large sliding French doors, or a huge double sliding patio door, maybe you should be considering jointly engineered large scenic sliding door systems designed and built in concert with Sing’s True Flat Team.

Well known for his “unbreakable mirror,” you might also want to consider, as many have, using Sing’s services for your next large mirror sliding door project.

Although not as tough as our original one piece door designs with a 50 year guarantee, our segmented doors still come with our patented Sing Core structure inside and carry a 5 year warp-free guarantee. And, they can be sold at a much reduced price.

Although not as tough as our original one piece door designs with a 50 year guarantee, our segmented doors still come with our patented Sing Core structure inside and carry a 5 year warp-free guarantee. And, they can be sold at a much reduced price.