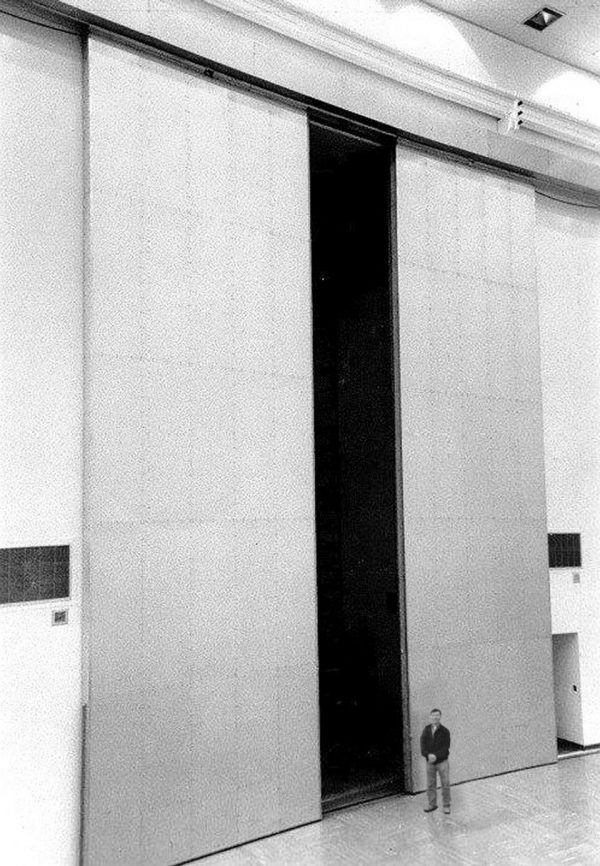

You will find Sing’s super large, oversized bottom rolling large sliding doors in use over a wide variety of industries such as aviation, commercial, agricultural, and industrial applications.

If you are looking for a lightweight oversized large sliding door that is stronger than steel pound for pound your solution to the size vs. weight ratio has finally arrived.

Due to inventor, Peter Sing’s patented and patent-pending large door technologies, door designers, and engineers of architectural doors have been empowered to take their conceptual contemporary ideas to the next level.

Now, even the largest of sliding doors can become manageable as complete solid units or as modular systems ready for assembly on site, with less need for heavy equipment with reduced threat of on the job injuries which is an ever-present risk when dealing with traditional large sliding bottom rolling doors, but not if your design has Sing Core inside.

These revolutionary lightweight and high-strength materials are having a huge impact on contemporary architecture and design especially in groundbreaking projects involving the largest rolling modern sliding doors in their respective industries.

Government and military applications now have a lightweight high-strength substructure made of Sing Core which can handle the added weight of any heavy weight additional material which may be soundproof and/or blast-proof, reducing the overall weight to one-third or less without compromising safety, security, or high performance.

And no other Eco-friendly, lightweight, dimensionally stable, and insulated building material is more high-precision (+/- .006 in.), stronger than steel (660+ PSI), or sustainable, which comes with a full 50-year warp-free and structure guarantee. 50 years!

When used as substrate material, the added insulation, which is also an integral component of Sing Core’s structural strength, helps add sound deadening characteristics while increasing climate control capabilities of any end product encapsulating it, saving lives and energy.

From beneath the sea (US Navy) to outer space (NASA) and throughout industries everywhere in between, Sing Core is changing the manufacturing methods when approaching the latest developments in the design and deployment of the largest sliding bottom rolling doors.

Whether inside the aerospace flying structures of the top aviation companies or the structures which house them while they are on the ground, lightweight high-strength Sing Core is making huge improvements in performance and reduced maintenance costs over time, when compared to traditional manufacturing methods inside and surrounding large aircraft designs.

While Peter Sing’s patented core material could be used in nearly any phase of construction, and has been used to build entire structures, from foundation to roof, everywhere in between, including most all interior furnishings, it’s premiere use with the highest degree of noticeable increased performance, is when it is featured inside any large rolling slider door system.

Steel buildings are made of it, without the need of a structure frame, which is having a noticeable impact for designers of modern metal building systems and the contemporary architects who are specifying Sing Core in their designs.

Large rolling doors with Sing Core inside can be used in any specific configuration, such as bi parting sliding doors, single-stack sliders, sliding doors floating, or fully suspended doors of large or enormous size.

Keep in mind that Sing’s large sliding bottom rolling door solution is not an out-of-the-box one-stop solution as Sing only provides the base door material which can be covered in nearly any flat building material in his factory located in the Pacific Northwest in Washington State.

Keep in mind that Sing’s large sliding bottom rolling door solution is not an out-of-the-box one-stop solution as Sing only provides the base door material which can be covered in nearly any flat building material in his factory located in the Pacific Northwest in Washington State.

Routinely, Sing’s base material is sent to metal fabricators, machine shops, millworks, or custom door manufacturers who supply the finishing details, prep for hardware, and arrange for installation of the behemoth sliding doors.

Not only are Sing’s base door manufactured in the United States but all the material inside these extraordinary one-of-a-kind door blanks are local sourced and each one is like an individually unique work of art fully made in the USA.

If you’re in the planning stages of your next project which may potentially feature large sliding bottom rolling doors, shouldn’t you check with your architect or door designer to see if you should have Sing Core inside your door?