Other Uses for Sing Core

Sing Core panels make amazing door and wall panels for a variety of applications, but what other uses do they have? We already know they’re the best choice for large or custom lightweight doors, or incredibly sturdy walls, but Sing Core has a wide range of other applications.

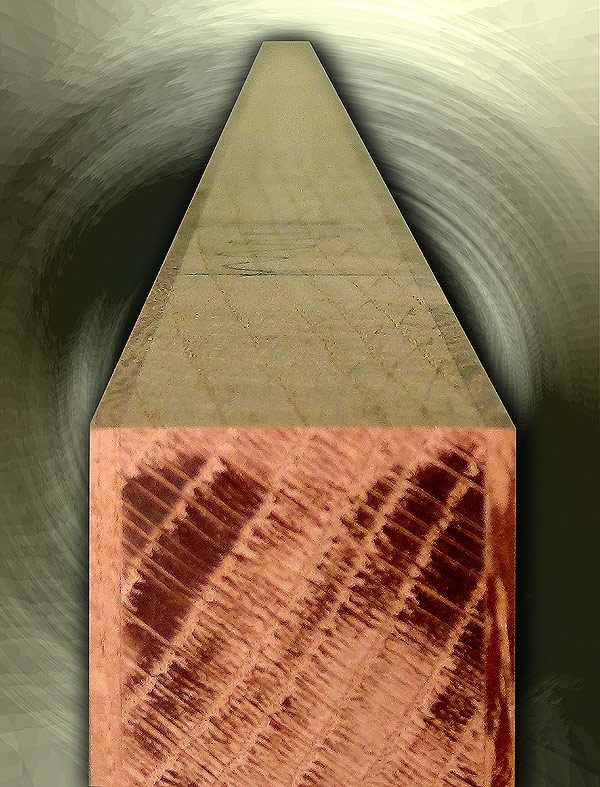

Tables or Countertops

Tables or Countertops

One of the more common non-door things we Sing Core panels used for is as a table or countertop. Our products work incredibly well for this, as some cases call for a very lightweight and easy to move surface, or others demand a large, custom-shaped table for places like a conference room. Either way, Sing Core panels work great for these applications. You can have the sturdy, warp-free, and high-quality aspects of a Sing Core door, but for your table or counter!

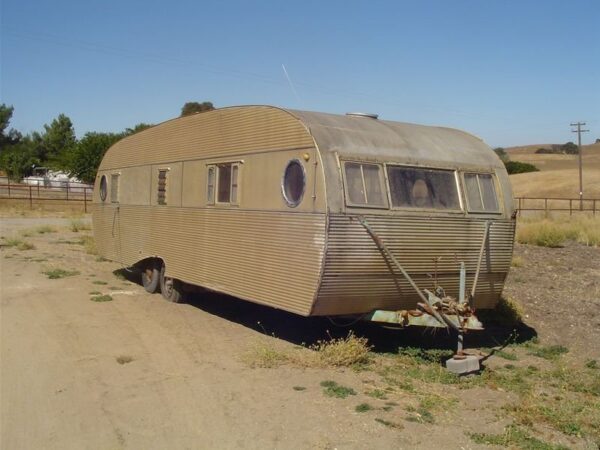

Mobile Cabinets or Containers

There are many different cases where one might need a mobile cabinet or container. Some businesses have rolling cabinets for secure equipment storage, while others need a durable and strong container that can be hauled from location to location. In the case of a storage cabinet, Sing Core works amazingly as it keeps the unit lightweight while also providing rigidity and security that normal, thin cabinet wood does not. Plus, with our new Security Door panel, this can take a cabinet from secure to impenetrable. Businesses that are constantly moving high-end electronics or sensitive documents can make especially good use of a Sing Core storage solution.

As for the case of strong containers meant to be hauled from place to place, Sing Core is again an excellent choice. People or businesses that find themselves regularly transporting hefty or large items may be looking for a reusable container that can guarantee protection for the cargo, without adding much to the weight of it.

Furniture

Sing Core panels can be made to unique sizes and shapes, allowing them to be used for miscellaneous furniture or similar applications. Sing Core has been used to make bunk beds, dressers, storage pieces, and more. This allows for the furniture to be transported incredibly easily, as it would weigh a fraction of a normal unit of the same furniture. We even use furniture made from Sing Core products in our own office, and they are still holding strong and working incredibly well.

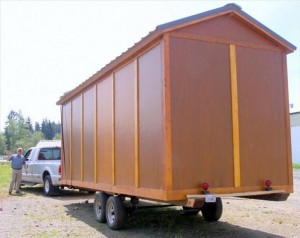

Floors

We often think of Sing Core panels being used as doors and walls, but they work just as well as floors. Particularly the floors of upper building levels, as they are incredibly lightweight, but have the structural integrity to withstand walking on. If you’re building a tiny house or some other small structure, using Sing Core for your upper floors may be your best bet, as it allows for easy construction and transportation.

And More!

Sing Core is more than just a door or wall panel, it’s a core that can be used in nearly any aspect of construction. Floors, stairs, furniture, and much more become a possibility with Sing Core. Plus, you still get our 50-Year Structural Guarantee, so you know you won’t need to do any replacing for a long time. When you look around at the things around you or think of new project ideas, consider Sing Core to make it the best it can be!