Sing Core is proud to announce that their Sing Sandwich panels are now.

Sing Core is proud to announce that their Sing Sandwich panels are now.

Why Build a Tiny House with Sing?

There are so many reasons but the most popular ones are:

Fastest and easiest tiny house building

Why spend weeks building your tiny house, when you can build your house easily with one or two people in a day (or hours depending on your assembly method)? When you build your tiny house using Sing Sandwich (or Sing Panel) you are using a lightweight, high-strength Sing Reinforced Structural Insulated Panel (SRSIP see specs) that is easy to handle and assemble.

4 Ways to Build a Sing Tiny House:

1. Hybrid Method

Using a combination of traditional 2×4 stick framing and Sing Sandwich panels

2. Caterpillar Method

Pre-assembled sections are joined together on site

3. Frameless Adhesion

|

Sing Sandwich panels are glued together to form a solid structure

4. Sing Modular Panels

Modular Sing Panels with your choice of biscuit joining or deluxe cam lock panels.

No Frame Needed

No need to frame your tiny house because Sing products all have a built-in torsion box structure that delivers less weight and more strength than any traditional stick-frame design and will not warp, bend or twist like traditional lumber.

Lightweight

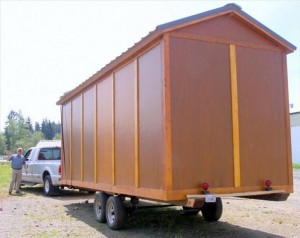

Sing products are a fraction of the weight of solid wood, plywood or particle board, making it much easier to handle and manage on site. Also, this could be a huge advantage if intend to build a tiny house on a trailer, making it much more cost effective to move without requiring a large heavy duty vehicle to build your own tiny house.

High strength

Due to the high-strength of Sing products (How strong? Six times [or more] stronger than honeycomb panels used in aerospace), your tiny house will be stronger than a traditional wood-framed structure. That’s why Sing structures can be used efficiently in disaster and severe weather condition for emergency or safety precautions. One of our clients said, “If my house ever gets picked up by a hurricane, all I have to do is find out where it landed and probably have to replace the glass. This thing’s solid, like a rock.”

Due to the high-strength of Sing products (How strong? Six times [or more] stronger than honeycomb panels used in aerospace), your tiny house will be stronger than a traditional wood-framed structure. That’s why Sing structures can be used efficiently in disaster and severe weather condition for emergency or safety precautions. One of our clients said, “If my house ever gets picked up by a hurricane, all I have to do is find out where it landed and probably have to replace the glass. This thing’s solid, like a rock.”

Insulated

Featuring pre-insulated Sing Core, you will keep cool in the Summer and warm in the Winter (R3.5 or R6.5 per inch) while enjoying the peace and quiet that comes with innate sound deadening qualities as well for increased privacy and safety in your little homes.

While the most sophisticated high-end small homes are made using patented Sing Core technology, it’s no wonder that homeowners and builders who are likely not to settle for anything less than the very best will seek out Sing products to build any structure, including their next:

Storage Shed Garage

You guess it! Why not have all these features available in your storage shed or garage?

Imagine building your structure quickly without heavy equipment or tools and having the safest and most secure environment for storage of your items that you want to be protected and unhindered by the storing process.

The Pacific Northwest is the home of Sing Core and in this wet and wild part of the United States we know how critical it can be to maintain a moisture-free environment for either short term or long term storage; the last thing that you want to do it to put your belongings at risk by exposure to mold or mildew.

Mold and Mildew-free

Mold and Mildew-free

The Reinforced Structural Insulated Panels have built-in insulation that protects your precious belongings so that you don’t have to worry about unnecessary exposure to mold and/or mildew making Sing RSIPs the best solution for safeguarding the storage of perishables including moisture sensitive items like photos, books and magazines. See: Comparison to other materials

How to Connect Sing Tiny House RSIPs?

There are many ways to connect your Sing Reinforced SIPs. See: Build a Wall for wall panel options for building the best modular homes.

How Do I get Sing Products?

You can also inquire about Sing products here, by contacting your architect or contractor, and even at your local lumber yard. For more information, see: Pricing

Designing, Ordering, and Building Your Tiny House

Some of the finest, high-end tiny houses are built using Sing technology. With the lightweight, durability, and affordability you can build the tiny house that best suits your needs. Click here to find out more.

Make money with Sing Core work from home

Make money in the comfort of your own home! Click here to learn more.