Build the highest quality furniture that could be guaranteed for 50 years. Not like old, heavy antique furniture. Weight of furniture used to be an indication of high quality but high quality may have been a more accurate description of irresponsible use of natural resources.

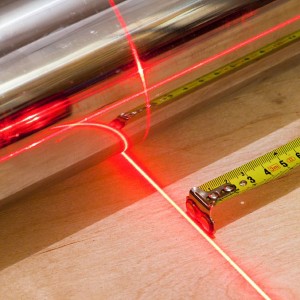

High Precision Natural Wood Composite

True green Sing Sandwich panels use less than 10% the natural resources of the equivalent solid wood panels with definitive value-added benefits including the  highest precision (within .006 inch) and will not warp, bend or twist even if using natural wood.

highest precision (within .006 inch) and will not warp, bend or twist even if using natural wood.

Lightweight High-Strength

The patented torsion box and rigid foam composite makes a lightweight, solid substrate that is stronger than honeycomb cores used in the aerospace industry rating at only 10 to 110 PSI while Sing Sandwich was independently tested at University of Washington and rated at 660 PSI (stronger than steel pound for pound). See: Core comparisons

High-end Woodworking

Life today is full of burden; never worry about your wood crafting not staying perfectly straight, or being difficult to work with or move. Lightweight, high strength furniture components are hard to come by among the furniture world.

There is a an enormous interest in importing cheap furniture due to low cost with reduced shipping and transport costs,  but paper honeycomb (like used in disposable furniture) is not manufactured to last very long, intended to be disposable and replaceable so that customers return to re-purchase products on a continuous basis creating a demand for repeat sales. Good business practice or not? You decide.

but paper honeycomb (like used in disposable furniture) is not manufactured to last very long, intended to be disposable and replaceable so that customers return to re-purchase products on a continuous basis creating a demand for repeat sales. Good business practice or not? You decide.

At Sing Core, we’re proud to help the top craftsmen and millworks to create the most high-end product that lasts virtually forever. In fact, we help artisans to create large oversize doors that are guaranteed to be  true flat and not to warp, bend, twist or cup for 50 years! Is it any wonder that these doors sell from $10,000 to $30,000 each? See: Clients list.

true flat and not to warp, bend, twist or cup for 50 years! Is it any wonder that these doors sell from $10,000 to $30,000 each? See: Clients list.

You Can Do This

You can use this same technology in your home improvement or fine woodworking – and you don’t have to order by the truckload to use it. All you have to do is contact your local Lowe’s Pro Desk and embrace sustainable woodworking by using less hardwood for wood furniture manufacturers.

Sing sandwich, packed with insulation, is the most affordable solution for lightweight and high strength without compromising quality or the natural beauty of solid wood by using less hardwood lumber. In fact, using Sing Sandwich panels you could make your own hardwood on demand.

Woodworking Revolution

Many manufacturers seek out Sing Sandwich also known as, “insulated torsion box plywood,” or RSIPs (Reinforced Structural Insulated Panels as opposed to sips which are not reinforced with torsion box)  to create masterful pieces of art and highly functional furnishings that will last the test of time. Sing Core is the woodworkers source assisting to create a perfectly flat, non-warping wood table, large doors and the antique furniture of the future.

to create masterful pieces of art and highly functional furnishings that will last the test of time. Sing Core is the woodworkers source assisting to create a perfectly flat, non-warping wood table, large doors and the antique furniture of the future.

Whether you’re building perfectly flat wood tables, the best kitchen cabinets, building a modular temporary wood wall, any of many applications or diy wood projects, incorporation Sing Sandwich panel may be the most significant recent improvement in your woodshop.

How to Buy Sing Core Products?

Use the convenient Lowe’s store locator to find a Lowe’s Home Improvement Warehouse near you or inquire about Sing Core at your local lumber yard. See also: Pricing

- Large honeycomb deadening panels