When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

Sing Core Doors

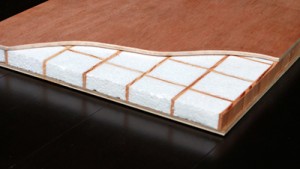

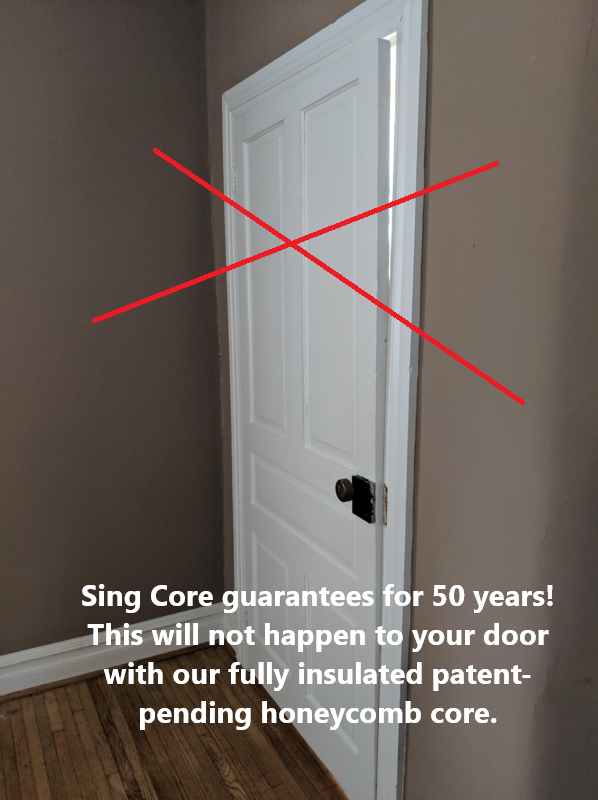

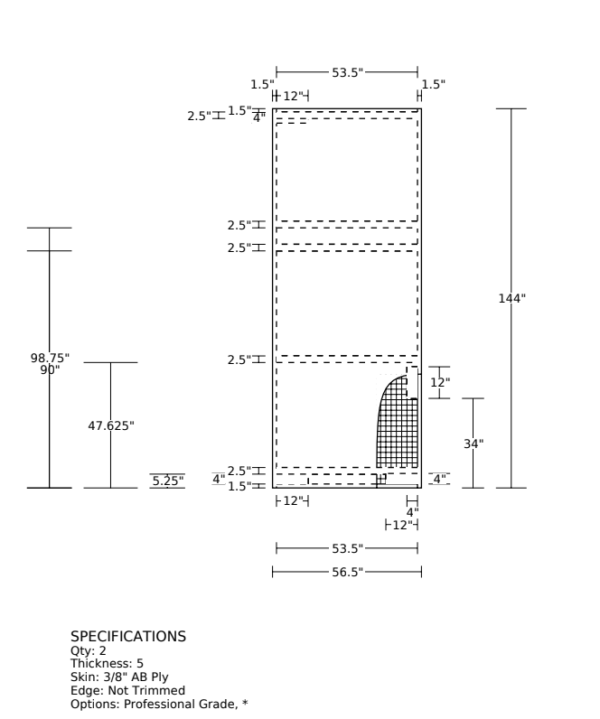

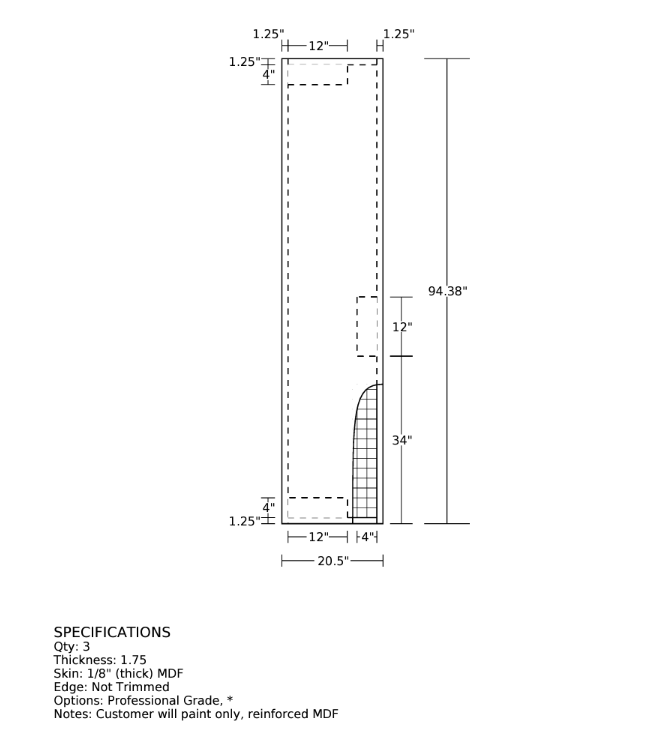

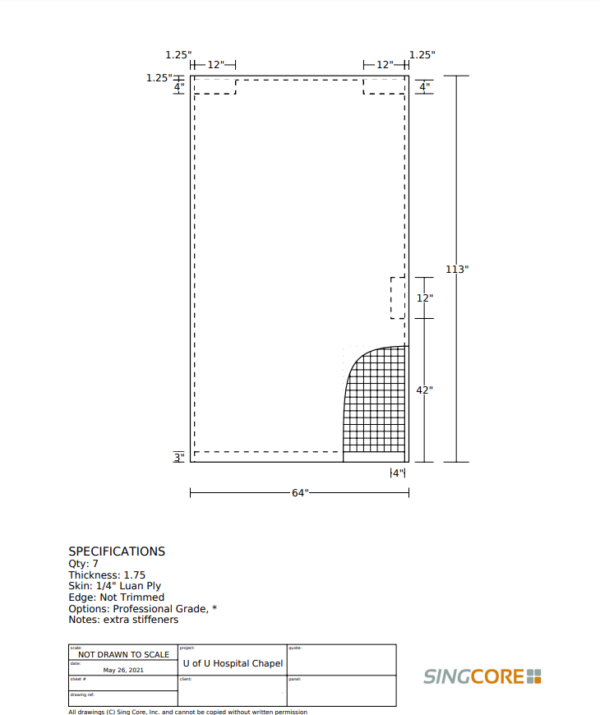

Sing Core doors are a revolutionary choice that combines the best features of other door materials. They are constructed using a patented technology that involves a honeycomb core between layers of quality hardwood. Sing Core doors are known for their exceptional strength, lightweight nature, and resistance to warping, bending, and twisting. Additionally, they offer excellent soundproofing qualities and can be customized to fit any size or style requirement. Whether you’re seeking a residential or commercial door solution, Sing Core doors provide durability, energy efficiency, and aesthetic appeal.

Solid Wood Doors

Solid Wood Doors

Solid wood doors have long been a popular choice due to their timeless beauty and natural warmth. Crafted from a variety of hardwoods, they offer a sense of luxury and elegance to any space. Solid wood doors are durable, can be refinished easily, and have a decent lifespan. However, they tend to be heavier than other materials, making installation and movement more challenging. Additionally, solid wood doors are susceptible to warping or expanding in high-humidity environments. Regular maintenance, including sealing and painting, is necessary to preserve their appearance and longevity.

a

Fiberglass Doors

Fiberglass doors have gained popularity for their durability and low maintenance requirements. They are resistant to rot, cracking, and warping, making them an excellent choice for areas with extreme weather conditions. Fiberglass doors can be designed to mimic the look of wood, offering a more affordable alternative without compromising on aesthetics. However, compared to Sing Core doors, fiberglass lacks the same level of strength and stability. They may be prone to dents or dings, and their insulating properties are typically lower than those of Sing Core doors.

a

a

a

a

Steel Doors

Steel Doors

Steel doors are renowned for their strength, security, and durability. They provide excellent protection against forced entry and are often used in commercial and high-security settings. Steel doors are resistant to fire, extreme weather, and pests. However, they can be susceptible to dents and scratches, which may require touch-ups or repainting. Steel doors also conduct heat and cold more readily than Sing Core doors, greatly impacting energy efficiency. Moreover, the industrial appearance of steel doors may not be suitable for all architectural styles.

a

a

Conclusion

Selecting the right door material involves careful consideration of various factors such as strength, durability, insulation, aesthetics, and maintenance requirements. Sing Core doors offer a unique combination of strength, lightweight construction, and resistance to warping or twisting, as well as boasting numerous optional features such as security, sound proofing, and more. They outshine solid wood doors, fiberglass doors, and steel doors in terms of their overall performance, making them an excellent choice for both residential and commercial applications. However, personal preferences and specific project requirements should always guide the ultimate decision. By weighing the pros and cons of each material, you can confidently choose the ideal door type that meets your needs while enhancing the beauty and functionality of your space.

.png/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:1280)

When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

Solid Wood Doors

Solid Wood Doors

Steel Doors

Steel Doors