Welcome to SingCore, where innovation meets collaboration to redefine interior spaces. Our pocket doors are not just a solution; they’re a partnership. Tailored exclusively for millworks, architects, and contractors, SingCore offers a seamless blend of elegance, efficiency, and reliability. Explore the world of SingCore pocket doors, designed for professionals who demand excellence.

|

|

Why SingCore Pocket Doors for Professionals?

1. Collaboration with Industry Experts:

SingCore exclusively collaborates with millworks, architects, and contractors, understanding the unique requirements of professionals in the field. Our doors are not just products; they’re a result of a partnership that prioritizes the specific needs of those shaping spaces.

2. Precision Craftsmanship:

Our commitment to precision craftsmanship sets us apart. The core of our pocket doors features patented Sing honeycomb panels, ensuring a lightweight yet sturdy design. This commitment to excellence in materials and construction guarantees doors that stand the test of time in both form and function.

3. Comprehensive Design Options:

Tailor your projects with our extensive range of design options. From classic wood veneers to sleek glass panels, SingCore pocket doors provide versatility to match the unique aesthetic preferences of your clients. Custom designs are also available, allowing you to create spaces that are both functional and visually stunning.

|

|

4. 50-Year Warp-Free Guarantee:

SingCore takes pride in offering an industry-leading 50-year warp-free guarantee. We stand by the quality of our pocket doors, ensuring that they maintain structural integrity for decades to come. This guarantee is a testament to our commitment to providing professionals with reliable, long-lasting solutions.

5. Exclusive Collaboration Process:

Working exclusively with millworks, architects, and contractors, SingCore understands the importance of a streamlined collaboration process. Our dedicated team is here to support you every step of the way, from design conceptualization to project completion.

6. Quiet and Effortless Operation:

Experience the tranquility of spaces with our pocket doors, engineered for quiet and effortless operation. The precision of our hardware ensures a smooth glide every time you open or close the door, enhancing the overall user experience for your clients.

Elevate your projects with SingCore Pocket Doors – a partnership built on precision, reliability, and exclusive collaboration. Join the community of professionals who trust SingCore to deliver exceptional results. Explore our options and redefine interior spaces with confidence.

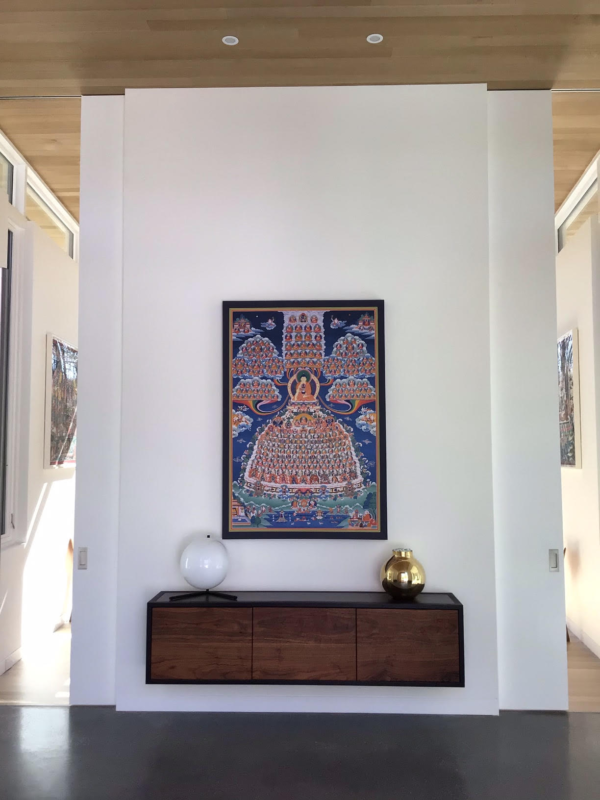

People often think of doors as simple barriers or entryways, but at Sing Core, we know that a door can be much more than that. Doors can be elegant accents to a room’s design, or a seamless way to change a room’s layout. If done right, they can even be part of a room’s main design feature, such as in the example we’re showing you today.

People often think of doors as simple barriers or entryways, but at Sing Core, we know that a door can be much more than that. Doors can be elegant accents to a room’s design, or a seamless way to change a room’s layout. If done right, they can even be part of a room’s main design feature, such as in the example we’re showing you today. Because Sing Core panels are made with a honeycomb core,

Because Sing Core panels are made with a honeycomb core,  A Sing Core door can be ordered to nearly any shape or size, and are strong, lightweight, and durable. One major concern with large doors

A Sing Core door can be ordered to nearly any shape or size, and are strong, lightweight, and durable. One major concern with large doors

Design Flexibility

Design Flexibility

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work.

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work. A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core.

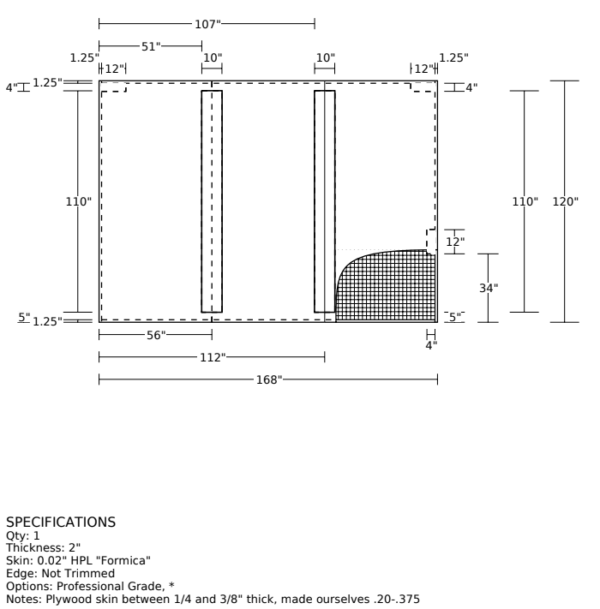

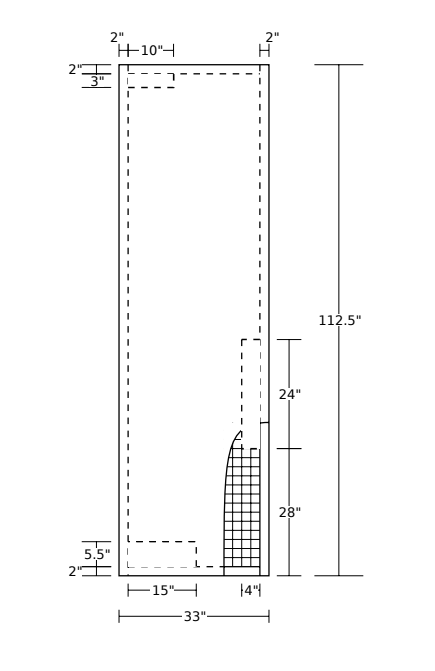

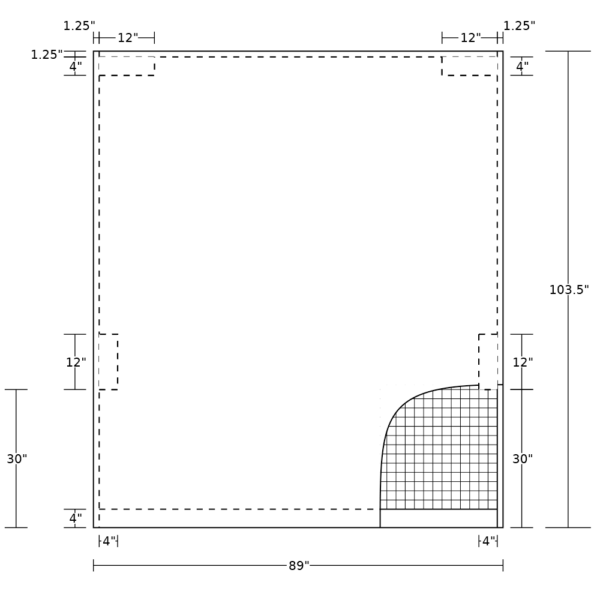

A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core. The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

Barn doors constructed with Sing Core offer

Barn doors constructed with Sing Core offer  Weight and Handling Issues

Weight and Handling Issues Warping and Moisture Resistance

Warping and Moisture Resistance Precision and Customization

Precision and Customization When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

When it comes to choosing the right door material, homeowners and builders face numerous options, each with its own set of benefits and drawbacks. In this article, we will explore the unique features and advantages of Sing Core doors, comparing them to three other popular types of door materials: solid wood, fiberglass, and steel. By understanding the characteristics of each material, you can make an informed decision that aligns with your specific needs and preferences.

Solid Wood Doors

Solid Wood Doors

Steel Doors

Steel Doors

The Project

The Project