In the artistic world of contemporary architecture design, creativity is the primary driving force expanding beyond the limitations of standard building materials. Architects and designers who yearn to express their artistic approach to groundbreaking structures and features with flair and high-precision detail are empowered by new advances in composite building materials, like Sing Core.

Creative visions come to life in the present day in projects with the most amazing degree of clarity and detail that might have taken thousands of artisan manhours in the past, by using patented and patent-pending Sing Core technologies with CNC artistry. The results can be most intricate and massive in scope and size using Sing Core.

MDF Doors

The primary focus of Peter Sing’s invention of Sing Core is in the large medium-density fiberboard (MDF) door venue. MDF is a fine surface material made of recycled wood products which makes it an excellent option for responsible use of wood fiber and sustainability for concerned architects and builders.

For voluminous designs on a budget, MDF is an inexpensive alternative when used in commercial and institutional projects when steel or prefinished wood may have been cost-prohibitive.

Admittedly, the bulk of Sing’s core being featured in MDF doors is far more practical than artistic. Using Sing’s core and assisted by his True Flat Team, the largest door companies and most prominent millworks in the country are able to create a lightweight MDF door that is stronger than any other MDF door. This enables door manufacturers to create lightweight MDF doors of immense size that can be guaranteed not to warp, bend, twist, or otherwise fail for 50 years.

The number one MDF door application of Sing’s MDF door substrate is in Paint Grade Doors.

Paint Grade Doors

When you are looking for the smoothest painting surface, then an MDF paint grade door is a clear choice. It is quicker and easier to produce a paint-ready door made of MDF over other wood door products.

When you are looking for the smoothest painting surface, then an MDF paint grade door is a clear choice. It is quicker and easier to produce a paint-ready door made of MDF over other wood door products.

The only problem is that MDF is heavy and unstable for heights exceeding 8 feet tall, or widths greater than three-an-a-half feet. Where MDF is concerned, size does matter.

To use MDF for large oversized paint grade doors, you need to get into the door engineering details of the door. Thankfully, the biggest and best door designers, millworks, and door companies are able to depend on Sing’s inventions and his True Flat Team to work out the details of the design.

The result? A lightweight, high strength, perfectly smooth flat surface ready for that special treatment, your expert paint, and great result. But that’s not all. These doors are guaranteed unlike any other door known to man.

50-year Warp-free Guarantee

Doors created with Sing’s composite of patented and patent-pending technologies are guaranteed not to warp, bend, twist, or otherwise fail for a full 50 years. No other large lightweight high strength MDF door can be guaranteed like that, which also includes a full 50-year warranty on the structure of the door as well.

MDF Veneer Doors

Next up, MDF veneer doors. When you’re talking about a large-scale job incorporating veneer for that high-end client who demands the very best, Sing’s patented and patent-pending veneer substrate is the premier solution for the most exclusive clientele.

Veneer can be sliced very thin, and any imperfection in the material underneath the veneer can become exponentially more apparent on the finished surface area. To combat this problem, the best millworks and veneer shops crossband to create a more natural surface area resulting in less noticeable imperfections.

Using Sing’s MDF underlayment for veneer provides a flawlessly smooth surface area to apply even the thinnest veneer for that perfect finish. And size? Well, the biggest and best veneer jobs have fail-free high precision Sing Core inside, which also matches perfectly with Wood Stave Doors as well.

CNC MDF Doors

For the architect, artisan, designer, visionary artistic creations can be brought to life with Sing’s lightweight warp-free CNC MDF door substrates. Imagine having a high-precision lightweight door canvas that is fully insulated for sound deadening and climate control capabilities that can be CNC sculpted to your heart’s desire.

That’s like a dream come true as your dream door is manifested via the efforts of top craftspeople and CNC artisans with the help of Sing’s inventions and his True Flat Team, all working together to see your idea become a reality.

To bring such a work of art to life may not have been impossible in the past, but to have a lightweight high strength configuration that was fully insulated and fail-free for 50 years guaranteed? Now that is something previously unheard of.

CNC Carved MDF Doors

CNC carving is taking the place of hand-carved projects all around the world, saving time and money.

Note that 3D carving can impact the surface area enough to make it less than stable. Using patented and patent-pending Sing Core technology as underlayment can solve the issues of carved surfaces creating challenges over time, even if the surface material is one that tends to move according to changes in the environment, like natural and exotic woods, which can be added to MDF and Sing Core, not unlike natural wood veneer.

-

-

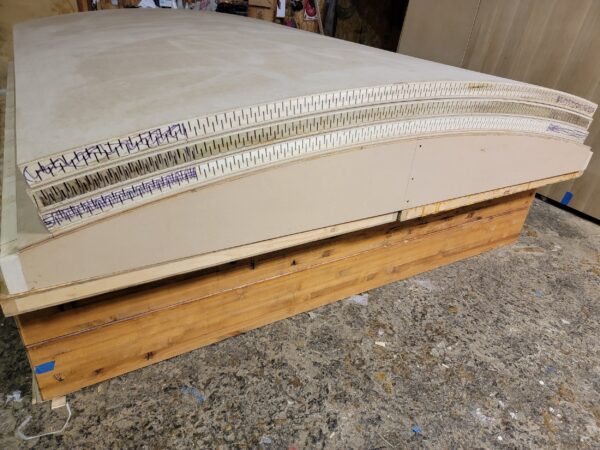

114 x 134 x 2 MDF Barn Door

-

-

-

-

-

-

Lightweight MDF Bookshelves

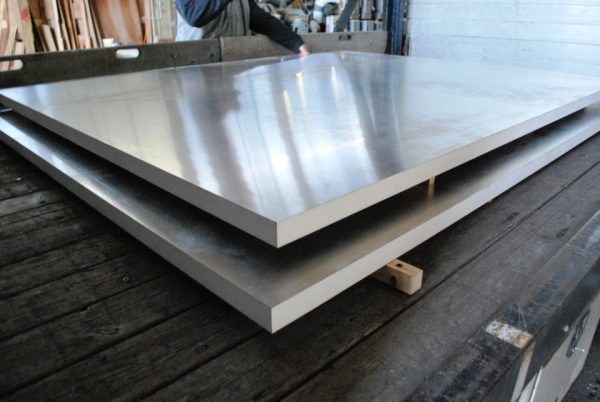

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work.

This customer wanted a door that could cleanly close and conceal the bar behind it, then upon opening have the doors slide and store inside the revealed room. This minimizes the footprint of the door system and allows for a much cleaner, less intrusive appearance and function. In order to make this work, our client needed a high quality, lightweight, and durable door panel, as something without these qualities simply wouldn’t work. A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core.

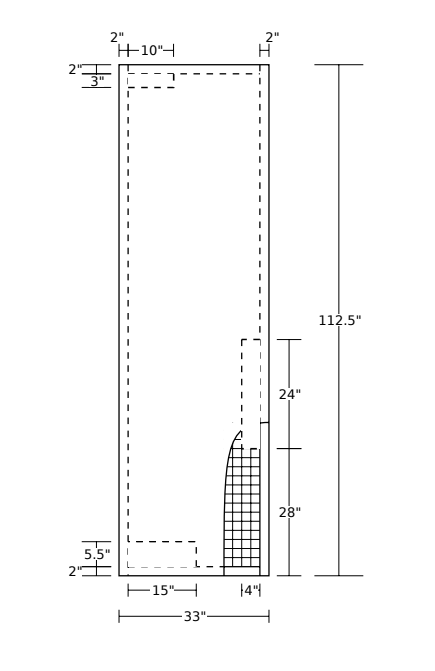

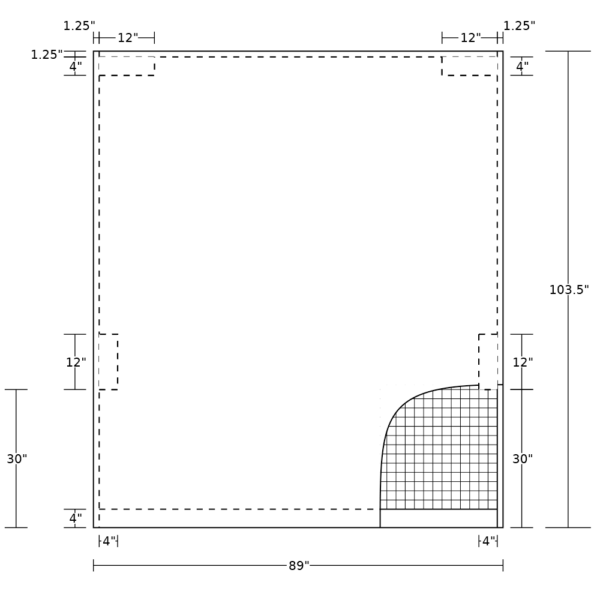

A lightweight panel was required, as anything heavy would ultimately wear down and break the hardware used to mount it. This is especially true in cases like this where precise and fine tuned hardware must be used to achieve the desired function. Heavy and unwieldy panels would greatly reduce the lifespan of these beautiful doors, which is one of the primary reasons this designer went with Sing Core. The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

The customizability of Sing Core panels is another great feature for unique projects such as this. The client had very specific requirements for their panels, which is reflected in the shop drawing to the right. This shop drawing shows the specifications for both of the panels used in this project. The panels needed to be exactly 33 inches wide, 112.5 inches tall, and 1.75 inches thick. These doors were made to professional grade quality and finished with MDF. Once sent to the client, they were able to provide the final details needed to turn these into the beautiful doors you see in these pictures.

The Project

The Project