If you’re looking for the best large sliding door, you’ve come to the right place. Sing Core specializes in creating the ultimate sliding door experience. We manufacture the only door substrate that you can use to create the most extraordinary doors in the world.

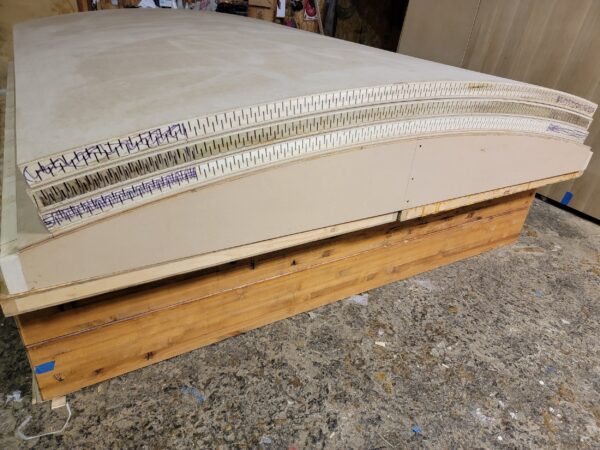

The above picture is a demonstration of Sing Core’s strength. Two 8’x9′ oak doors (approx. 800 lbs.) laying on top of two 7’x8′ curved doors. The curved doors had no visible movement due to the high strength of Sing Core. As you can see, the eye plate is so small but can support such a large door panel.

These three curved panels measure 7’x8′ and are built to the highest precision and strength to last a lifetime.

Here is another example of a curved door with a smaller radius built with the exact same expertise.

Sliding Doors

The deal with sliding doors is that you want your sliding doors to remain straight and true throughout their service life. Architects, designers and end users face the issues associated with sliding doors, but rest easy knowing your sliding door has Sing Core inside.

Problems with Sliding Doors

The first problem with sliding doors is that they tend to move (warp, bend, twist or cup) compromising the doors’ performance. Especially in the case of sliding doors because they hang parallel to a wall (like sliding barn doors), next to another door (such as double sliding doors) or within a wall (like sliding pocket doors). If the door does not stay straight, it can wreck either the sliding doors or the surfaces they slide against, or both.

One way to overcome the warpage issue is to utilize stronger materials which tends to greatly increase the weight. The downside is that increasing the doors’ weight creates another set of challenge. For example, heavier doors require heavy duty hinges to support the doors. Heavier doors also require more labor for handling, installation, and any servicing it may require.

As you can see, this massive door is 8’x9′ and remains perfectly straight. So straight, in fact, that it is perfectly freestanding on end! If there was even the slightest amount of warpage, then this door would topple over.

Sliding Door Design Problems Solved

Architects and engineers are constantly perplexed with the problems associated with sliding doors, fortunately an Eco-friendly composite solution made in the USA, helps to solve the problems associated with faulty sliding door design. Patented Sing Core, along with their true flat door team, can help to create sliding doors that will remain straight and true far beyond the service life of any other sliding doors. By working with Sing Core’s design staff a combination of Sing Core and patent-pending sliding door stiffening solutions can create perfect sliding doors that are lightweight, high strength and can be guaranteed not to warp, bend, twist, cup or otherwise fail for 50 years.

These oak doors are manufactured with the highest precision. As you can see, there is no gap between the two oak doors. If they were slightly warped, or a little uneven, there would be a gap showing, possibly more.

The Perfect Large Sliding Doors

The best custom door manufacturers and millworks who offer long warranties on their large doors have a secret inside each one of their high end professional sliding doors: Sing Core inside. A properly designed and built large sliding door with patented professional Sing Core inside can be guaranteed not to warp, bend, twist or otherwise fail for 50 years.