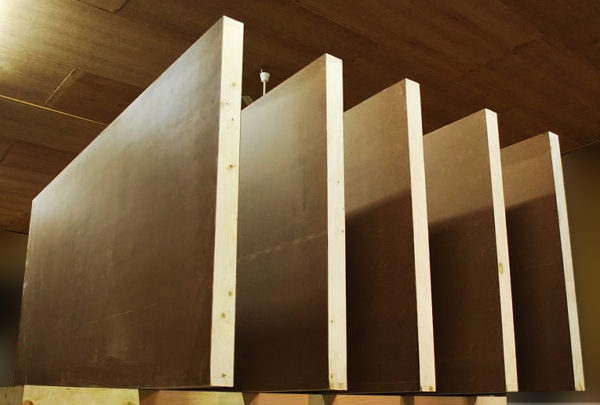

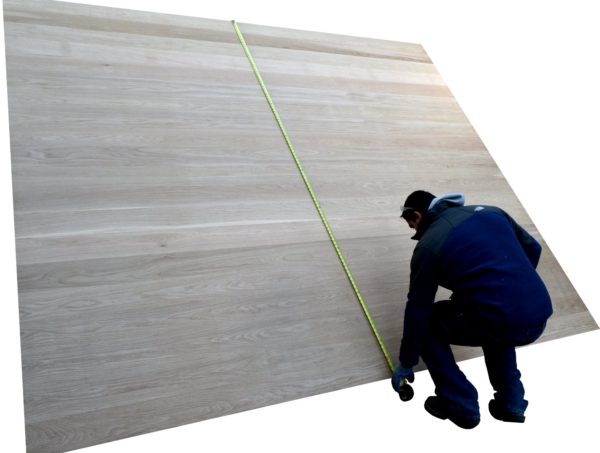

10×12 ft 3″ thick warp-free 1/8″ oak 520 lbs

True flat technology is based on expertise in building any door that can be guaranteed true flat and stay flat. This composite science includes the proper proportions of Sing Core, aluminum and/or other materials and bonding agents based on your requirements or specifications. In this way each Sing door is a work of art.

One of the challenges in building any wood product of any dimension where the customer desires a perfectly flat surface over long spans is insurmountable in many circumstances.

This is the proven niche specialty service provided by Sing Core to the worlds most high-end, demanding, high-profile millworks and end users for years. Due to the unique properties of the patented Sing Core material, true flat designs can come to life and deliver superior satisfaction while carrying a 10 year structural guarantee.

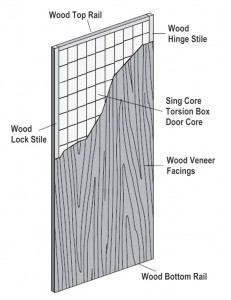

AWI standards may allow for a certain amount of deflection over long spans, the patented Sing Core material far exceeds deflection allowances of other materials, due to its torsion box design while remaining true flat.

This is why the most prestigious millworks in the United States turn to Sing Core for their large, oversize doors, though they have the added benefits of having an end product that is:

Eco-friendly

Eco-friendly- Renewable

- Dimensionally stable

- Extremely Strong

- Light weight

- Insulated

- Sound deadening

- Easy to machine

And could be customized to include:

- Waterproof

- Fire retardant

- Bullet-proof

- Any Thickness

- Almost unlimited skin options

- Fast turnaround

The True Flat Challenge

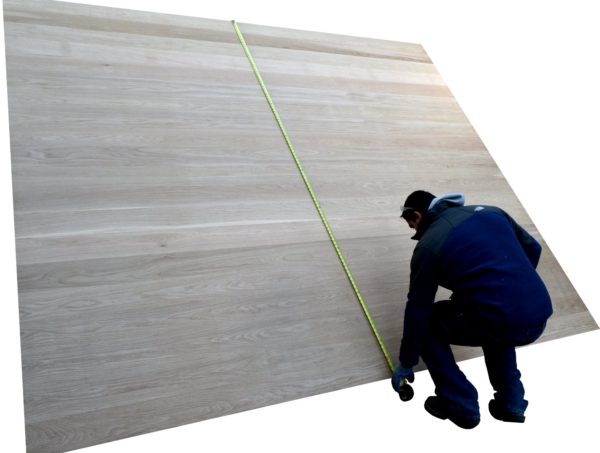

The true flat door is a challenge for architects, door manufacturer, millworks and general contractors, especially if the door is 1 inch thick (or more), over 8 feet wide and/or 16+ feet tall.

If you’re looking for the answer, you might Google search how to build a true flat door.

Oversize doors present the biggest challenge for true flatness, but they also present other issues that must be dealt with in high end homes and/or commercial applications in terms of weight and strength. Again, let’s see what Google has to say about lightweight high strength true flat?

The clear answer is Sing Core; a new invention of material that is playing a major role – not just in building large doors – but almost anything that requires (or desires) to be Eco-friendly, functional yet elegant for inside/outside a home or in building and construction that needs to be light, strong and sustainable

Aluminum composites are common in the aerospace industry, but are cost prohibitive and not user-friendly for mill working or broad earth-bound use. Sing Core is designed to be used in millworks and does not require any specially-trained labor or specialized equipment; treat it just like you would any other standard wood-based substrate material.

Sing Core’s true flat process utilizes vertical grain torsion-box/foam-core/aluminum composites to deliver the solution. Contact us for more information, and if you like, we will show you how to integrate this new technology into your operation.

Meeting the Highest Demands

We maintain the highest degrees of integrity when meeting the requirements of our clients, and their customers, assuring complete satisfaction. Most importantly, proper communication is the key. If you have certain expectations – and you let us know – our team can deliver the product that matches your specifications.

We maintain the highest degrees of integrity when meeting the requirements of our clients, and their customers, assuring complete satisfaction. Most importantly, proper communication is the key. If you have certain expectations – and you let us know – our team can deliver the product that matches your specifications.

Simply by providing us with your dimensional requirements:

- height

- width

- thickness

along with what your preference for visual presentation (exterior skin material) and performance expectations are, we can provide you with the solution to best suit your application.

How Do We Do It?

When you explain to us what your expectations are, we know how to create the product that meets or exceeds your expectations. For instance, if you require a 17 foot tall oak pivot door that is true flat.

First of all, if the pivot door were solid oak, it would fail the standards test due to the raw material. Natural wood will warp, twist and crack if left to itself. Not to mention being heavy in weight. The excessive weight is an added strain on the integrity of the structure and hardware, increasing maintenance costs over time.

Our designers will likely prescribe a solution that begins with a Sing Core base material in the center which is by itself perfectly flat. Adding oak wood staves is where the problem comes in; because natural wood is unstable and will compromise the overall structure. To combat this issue, our team may fuse the Sing Core material to aluminum to complete the substrate composite. Then, when the exterior oak faces are applied to the structure; like magic, the result is a lightweight, super strong solution that can be perfectly flat.

Our designers will likely prescribe a solution that begins with a Sing Core base material in the center which is by itself perfectly flat. Adding oak wood staves is where the problem comes in; because natural wood is unstable and will compromise the overall structure. To combat this issue, our team may fuse the Sing Core material to aluminum to complete the substrate composite. Then, when the exterior oak faces are applied to the structure; like magic, the result is a lightweight, super strong solution that can be perfectly flat.

The resulting Sing Core lightweight solution does not compromise the structure or the hardware eliminating expensive repairs and/or maintenance.

That’s just one example. Some of the materials used in our true flat composite resolutions that battle the temperature and moisture weaknesses that accompany utilizing natural components (like wood) include

Our lifetime of experience dedicated to solving the challenges of architects, designers and craftsmen who serve the most prestigious clientele, especially in terms of sustainable, lightweight, super strong and true flat solutions that maintain structural integrity over many years, while retaining the beauty and elegance of natural wood (or any other desired external material).

Metal is used across many industries. Metal honeycomb composite is the leader in honeycomb cores used to create stronger and lighter metal panels as well as posts and beams using much less solid metal.

Sing core is the leading technology of metal honeycomb composite material that solves our future Eco-friendly energy solution by using Sing metal honeycomb composite at a fraction of the weight of solid steel, but is stronger, lightweight, and available in steel plate, steel beam and steel panels.

Tell the US Energy Department to do some home work and research the Sing solution. If you believe Sing Core will help us use less metal thanks to Sing honeycomb metal.

Case study #1: Do not waste more precious metal if you could use Sing Metal honeycomb panel, post and beam.

Replace steel by using Sing 13 ft x 3 ft x 1 inch Sing honeycomb metal plate for use in conveyor.

1 Advantage: Precision true flat – within thousands of an inch – the majority of metal fabrication relies heavily on welding that causes the metal to deform. Sing metal uses structural glue, nuts and bolts instead of welding metal plates onto the steel frame which takes more labor, energy and end the product will not match the same precision as Sing Metal honeycomb panels.

2 Easy to fabricate and install – lightweight metal is safer to process, costs less to transport and uses less labor to install.

3 Less cost: Solid metal takes many times more metal than Sing Metal panels, posts and beams. It is expensive to transport, takes more energy to process and the most important thing is that Sing Metal is much less expensive than solid metal planks or sheets. If the strength, lightweight and Eco-friendly attributes are considered you may never go back to solid metal again.

Case study #2: If your seeking to improve your products with greater precision, true flat doors or panels, walls, floors, ceilings, RVs and/or boats then we’d like to teach you to Sing.

This is the latest technology to build true flat doors. If we are able to build a true flat door then you can believe that we could make true flat floors, ceilings, walls, etc… all lightweight, high strength, long lasting and endless benefits just by Singing with us.

This is the latest technology to build true flat doors. If we are able to build a true flat door then you can believe that we could make true flat floors, ceilings, walls, etc… all lightweight, high strength, long lasting and endless benefits just by Singing with us.

Doors are a challenge for door manufacturers and mill works if the door is over 8 ft in length and less than in inch thick.

One of the Sing aluminum honeycomb panels are used as door substrate. It used in almost all major high end residential and commercial door applications due to the true flat characteristics. AWI standards for true flat include deflection of ¼ inch, which is unacceptable for Sing Core. We can minimize deflection to 1/8th or even 1/16th according to your pre-arranged specifications and application requirements to ensure satisfaction.

But if you have a door over 12 ft – even over 16 ft tall – and less than 1.5 inch in thickness and you are wishing to have the least deflection than you need to contact www.singcore.com to find the true flat solution which is use aluminum panel as substrate than add MDF or AB plywood for paint grade door or by cold or hot press to add finish veneer to build the most beautiful, strong, lightweight eco friendly door.

Doors made of Sing Aluminum honeycomb substrate do not need to acclimatize due to there being no moisture difference on either side of the door substrate.

Sing Aluminum honeycomb door substrate can be machined or drilled just like wood without retooling or damaging your blades. It is easy to glue with proper clean up procedure.

Large over size doors for high end building project require the true flatness. Patented Sing Core is the ultimate solution for high end mill work across the country.

Please click to see clients list of those who use Sing Core doors.

The string should be straight. If there is a gap between the string and the door’s surface, you may have a warped door.

The string should be straight. If there is a gap between the string and the door’s surface, you may have a warped door.