There are many ways to build large doors with Sing Core inside, the only doors that can be,

Guaranteed Warp-free for 50 Years

When it comes to oversize doors, one door stands out above the rest for high-end applications; see comparison. Look for these features in your door for the most discriminating taste(s):

- Available in any size

- Lightweight

- Strong (stronger than steel pound for pound)

- Insulated

- Sound-deadening

- Guaranteed True Flat

- Resistant to warp, twist, crack & rot

- Standard 10-year warranty

- Professional 50-year warp-free guarantee

For more detailed information on our doors, see our Architectural Specifications.

Though Sing Core Doors are available in nearly any wood species, our standard varieties include:

|

|

|

|

|

| MAPLE | CHERRY | OAK | VG FIR | WALNUT |

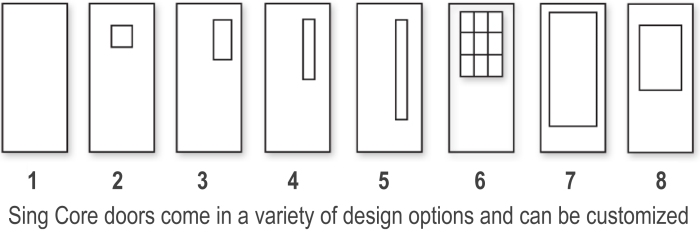

Note: Door designs can be modified to meet your specifications and requirements an may include the application and bonding of any flat building material. Please feel free to inquire for more information.

1. Paint Grade Door

2. Wood Grain and Wood Stave Door

3. Hardwood Plywood Door

1 Paint Grade Door

Our most popular door blanks are paint grade, and can be made to your specs including surface materials of,

- Birch ply (most common)

- Wood plywood

- MDO

- HPL

- Other material, as specified

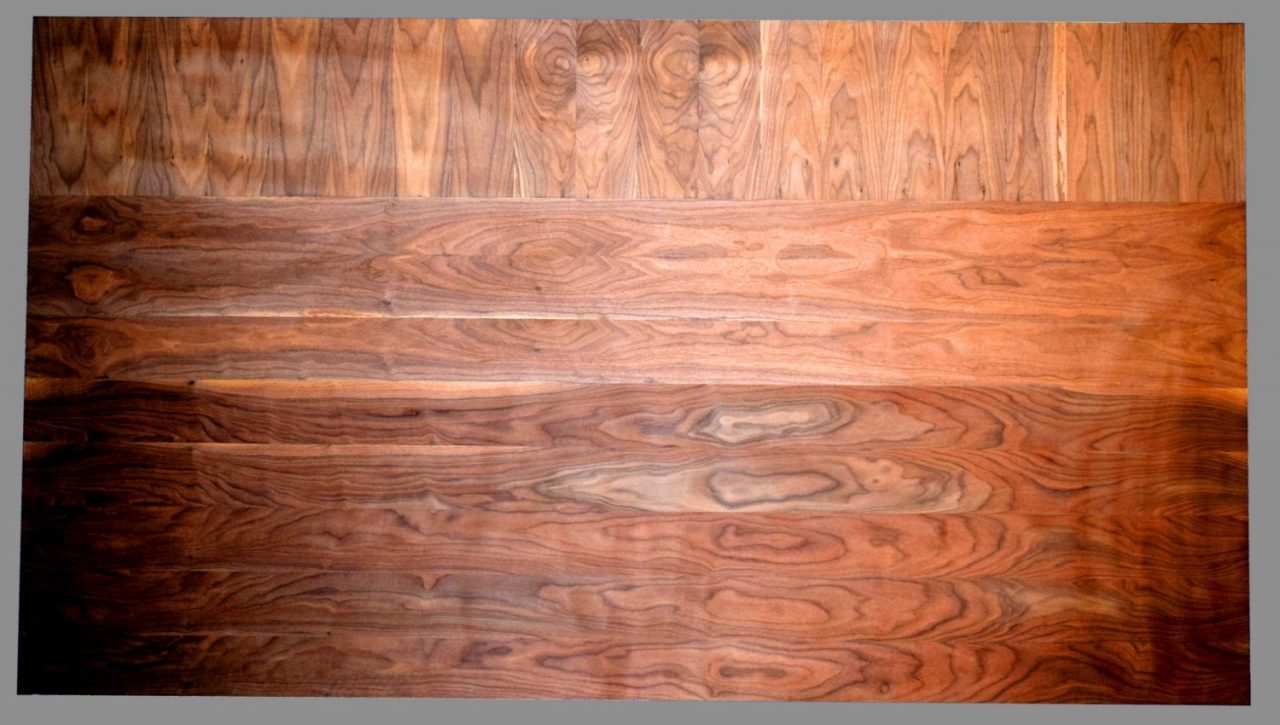

2 Wood Grain and Wood Stave Door

Besides paint grade for the surface, we also provide solid wood stave laminate on both sides of the sliding door. Wood stave is easy to work with and will last. Your Sing wood stave door will be more high precision than solid wood door (less warping, and twist and crack) due to Sing Core’s extremely high tolerance (+/- .006 inch) and, rigidity and high strength (660+ PSI) and professional grade wood grain and wood stave doors are certified and guaranteed not to warp, bend, twist, or otherwise fail for 50 years.

Sing Core provides hot-press ready door blanks to door manufacturers who add wood veneer on both sides of Sing door blanks which are made of Luan skin or marine grade plywood sandwich with patented Sing Core in the middle, solid wood around 4 edges and wood block implants where needed for hardware.

|

|

Note: Veneer has to be handled very carefully every step of the way during production (we prefer to let the millworks handle this delicate procedure) and it is easy to damage by users over the years (but wood stave can be easily sanded and repaired).

- Sliding door

- Black walnut sliding door

- Black Oak

- Bi-directional Walnut

- Bi-directional Walnut

- Oak

- Oak

- rift white oak pivot door

- Teak

- Cedar

- Walnut

We offer a very good price for wood stave doors, the cost is not much more than wood veneer doors.

3 Hardwood Plywood Door

We could make door with hardwood plywood as an effective way to make super large doors that you can stain any color. Up to 4×8 doors have no seam, but by orienting the grain horizontally, you can achieve a nearly seamless presentation on really big doors or extraordinary size.

Available in any available wood species, most common are Sapele, Oak, and Maple ply.

- Birch Plywood

- Plywood

- Marine Grade Ply

Sing Hardwood ply door has excellent strength, yet is lightweight, features good insulation and better sound deadening qualities than solid wood plank doors.

Applications -> Building Components -> Doors -> Door Finishes