Sing Core’s Famous 50 Year Guarantee

Sing Core’s Famous 50 Year Guarantee

At Sing Core, we are well known for the high quality door and wall panels we manufacture. Their many qualities allow them to speak for themselves, though our famous 50 Year Guarantee is what really sends them to the top. Our panels are strong, lightweight, and make beautiful doors, but without a warranty those traits are far less valuable. Sing Core panels, however, come with a 50 Year warp-free and structural guarantee. This turns those fancy words into a real promise, which is more than most other panels on the market can claim.

Why 50 Years?

Why 50 Years?

50 years is a long time, longer than any other custom panel manufacturer is willing to claim. It comes with significant risk, as over the course of 50 years, a lot can happen to the product. Temperature and weather exposure can cause it to warp, frequent use can cause faults in the structure, and more. With Sing Core panels, this isn’t a concern. We don’t just promise 50 years and hope the panel survives, we promise 50 years because we know it will. In fact, Sing Core panels are designed to last far longer than 50 years, though we feel 50 years is a good amount of time to prove the durability and quality of our product, and is far more than what the rest of the industry is willing to offer.

Warp-Free Guarantee

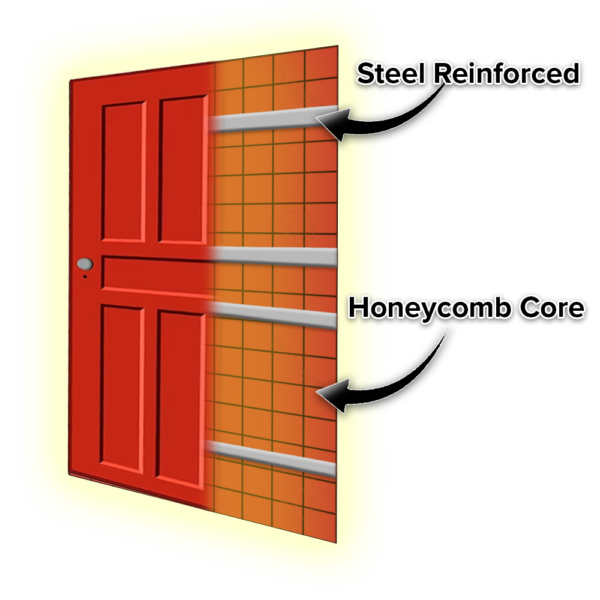

Part of the 50 Year Sing Core Warranty is a promise that our panels will never warp. Warping presents a huge concern for doors and walls, and particularly large doors are at higher risk of warping just due to their size. A warped door can lead to all kinds of issues, such as sealing problems, difficulty opening and closing, and even up to full failure of the structure or function. Sing Core panels are built using our patented and patent-pending designs that guarantee they will never warp, so this completely eliminates the risk of your door or wall failing in that way.

Warping may seem unlikely, but it is incredibly common and can happen for a number of reasons. In areas with volatile temperatures and harsh weather warping is more likely to occur, especially when regularly exposed to moisture such as rain or snow. Even in regions with calmer weather, warping can happen seemingly for no reason. Sing Core panels will never warp, and that is what our 50 Year Guarantee is built on.

Structural Guarantee

In addition to never warping, our panels also come with a structural guarantee. This means that if the door fails in a way related to the manufacturing process, we will make it right. Our panels are crafted of high quality materials in a controlled environment and are solid as a rock, while still being lightweight. We also inspect them all before sending them out, so they should never fail. However, while we are confident in our product, we want you to be confident in it, too. That’s why we offer a structural guarantee as a part of the warranty, so that you know you’ll be covered if your panel ever does fail.

How to Use Your Warranty

In the unlikely event that you need to make use of your warranty, the process is very easy. All you have to do is contact us with the information about the initial panel order and what went wrong, and we will get the process started. During the process you may be asked to provide pictures and information, but rest assured that we will make it right.

Thank you for using Sing Core!