Lightweight Composite Panel Laminators

Sing Core is proud to be the premiere laminator working exclusively with only the best architects supplying the most high-end millworks to solve the problems associated with other laminate panels.

Sing Panels are more lightweight, high-strength, true flat and Eco-friendly than any other laminated panel in the industry, and even compared to off-shore products, Sing […]

Architectural Specification Substitutes

Due to being the newly invented and possibly the most significant improvement in building materials in the last century, it is not uncommon to see Sing products recommended as substitutes for products in the original specifications initially specified by architects. Even though Sing Core is new, we are not that new […]

Lightweight MDF

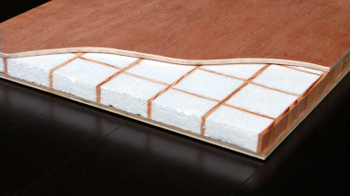

Building materials such as plywood, MDF, particle board, LVL, Parallam and laminated beams are standard building materials that have been around for years. The newest technology on the forefront of evolutionary building materials includes honeycomb composite materials, like those used in the aircraft industry.

Introducing Lightweight MDF

Sing Core is raising the bar […]

Lightweight Green Patented Plywood Export to Asia

Monday, July 18, 2013 For Immediate Release

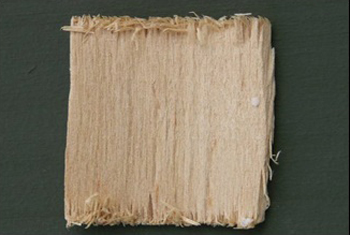

The first container of green patented plywood exported to Asia is the start of something new. Inventor, Peter Sing from McCleary, Washington, invites Americans to join his grass roots eco-revolution.

This might be the first container of a new, lightweight plywood manufactured […]