One of the greatest attributes of your sliding door is the actual sliding performance of the sliding door, especially closet doors. See our new C Series line of Affordable Barn Door and Sliding Closet Doors.

Certainly, upon installation, your wood sliding door or interior pocket doors may perform superbly… but for how long?

It may be important for you to seek out how to make a sliding door that has a high level of performance. And what are the benefits that will increase the performance of your sliding door? Consider:

| 1. | True flat | straight and will stay flat |

| 2. | Lightweight | 1/3 the weight (or more) |

| 3. | High strength | stronger than steel lb. for lb. |

| 4. | Insulated | starting at R3 |

| 5. | Sound-deadening | starting at SCT 30 |

| 6. | Resistant to warp, twist & rot | to meet your specifications |

| 7. | Longevity | built to last for centuries |

| 8. | Guaranteed | 10 to 50 year guarantee |

| 9. | Eco-friendly | sustainable true green technology |

Only one door company can deliver a sliding door that delivers high marks in all those important features. See our comparison chart comparing Sing Core doors panels to other door core materials.

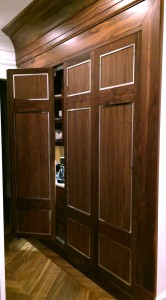

So if you’re looking for closet ideas, sliding closet doors or double closet doors for your wardrobes that are true flat and stay flat without warping or twisting, then you might consider the Sing Core alternative.

So if you’re looking for closet ideas, sliding closet doors or double closet doors for your wardrobes that are true flat and stay flat without warping or twisting, then you might consider the Sing Core alternative.

Our industrial sliding doors and marine sliding doors are specially designed to survive the rigorous changes in the elements including exposure to extreme weather conditions.

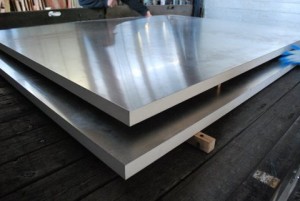

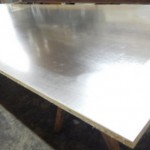

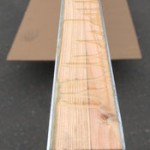

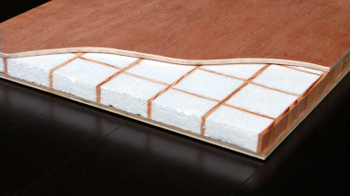

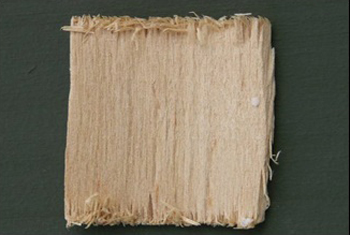

The secret lies within the core of the sliding door which is basically one of our honeycomb panels (which is also available in aluminum honeycomb panels) that is the foundation for the superior performance of sliding doors that must remain perfectly straight to reduce maintenance over time.

Even though any Sing sliding door can be finished in any flat exterior building material, the aluminum sliding door is extremely popular and can easily have any other surface material, like any wood species, concrete, glass, FRP, HPL, and can be made to be water-resistant or bullet-proof.

The Sing sliding door is not only a light door that reduces strain and wear on the door hardware, but it is also stronger than metal hanging sliding doors and even make magnificent plastic sliding doors.

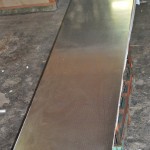

And when it comes to big sliding doors, our custom oversize sliding doors continue to deliver the best results enjoyed by the top millworks and door companies in the world service the most demanding high-end users.

- high strength non warping sandwich sing honeycomb

- Interior sing honeycomb high strength non warping honeycomb sliding

- Large honeycomb sandwich door

- Insulated Sing sandwich door

- Your sliding door could be a giant chalk board or magnetic display

- true flat sing honeycomb sandwich

- lightweight high strength sing honeycomb sandwich

- Flush Door Closet

- Lightweight high strength moveable wooden non warping doors

- interior true flat stronger than steel lightweight

- oversize lightweight high strength honeycomb door

- large oversize lightweight high strength sing sandwich door

- lightweight high strength large honeycomb door