Home -> Products -> Material Options -> Metal -> Galvanized Steel Metals

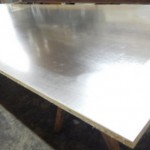

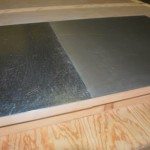

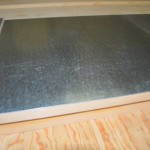

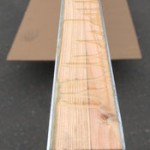

Galvanized steel Sing panel (above) is made of 20 gauge thickness .40 inch thick and weighs 1.65 lbs. per sq. ft.

Sing galvanized steel is lightweight, insulated, stronger than steel pound for pound and just one of the metal panels in the Sing Metal Collection.

Sing galvanized steel features a less expensive exterior finish that is impervious to the elements resisting rust, wear and tear and rot more effectively than other forms of metal surface materials.

While remaining structurally sound, galvanized metal treatment reduces maintenance due to incidental damage or compromise.

The galvanized surface can sustain damage without compromising the protective surface material.

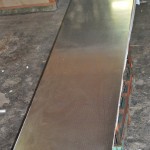

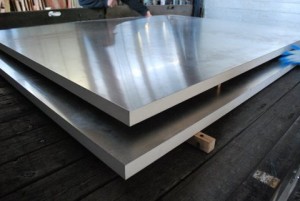

One of the most impressive attributes of Sing galvanized metals is these steel panels are not limited in size, including large and oversized without having to join separate pieces on job site. Available in almost any length, width, thickness… even custom shapes.

For instance, our most popular sized Sing galvanized steel panels are 5 ft. wide by 20 ft. long. We do this every day, and each one is the Eco-friendly alternative that is proudly Made in the USA of the same structural material that is used as substrate prior to adding wood-based door surface material (or paint grade) true flat doors featuring our 50 year guarantee to be true flat and stay flat. These galvanized steel panels excel in temperature resistance, high tensile strength and durability.

Sing galvanized metal is sought after for industrial signage, building industry, trade show displays, store fixtures, furniture manufacture, marine industry, and due to its unique ability to outlast other materials with superior corrosion resistance.

Other trending applications include automotive industry, construction, electrical towers, large magnetic signs, equipment enclosures, sheds, tiny houses, ramps, temporary bridges, modular temporary buildings, structures and flooring, industrial machine shops and assembly lines.

Galvanized steel equipment enclosures

- Exposed Equipment

- Galvanized Steel Enclosure Panels

- Finished Equipment Enclosure

Used in your manufacturing plant as a high precision work bench as an alternative to traditional cold rolled steel or wood base work benches that are made of solid material. The traditional solid material will move according to the temperature or moisture change. Alternatively, Sing galvanized metal panels are made of patented Sing Core – which is made of 90% air – and will have little or no movement, especially when compared to any other solid material. Sing core is made with +/- .008 inch instrument grade precision or less unlike average wood or metal which could not match such high tolerances.

MAGNETIC GALVANIZED PANELS

Sing galvanized magnetic panels are great for displaying artwork, documents, pictures and important information while maintaining your great interior design. Perfect for any location including the office, kitchen, kid’s room, and garage using magnets to display so you don’t damage your originals.

Used as exterior signage, magnetic and/or display panels, Sing galvanized delivers high precision and superior performance results. Perfect for use as a magnetic wall in the home or office for organizing your data center.

Depending on your application(s) and specification(s) only Sing galvanized metal panels can be guaranteed to remain structurally sound for 50 years (though they are designed to last for centuries).

Intended for use where greater corrosion protection is required without painting. Sing galvanized steel panels are lightweight and therefore require less manpower, heavy equipment and/or transportation costs.

Intended for use where greater corrosion protection is required without painting. Sing galvanized steel panels are lightweight and therefore require less manpower, heavy equipment and/or transportation costs.

This provides the end-user with huge cost-saving for delivery and installation more safely with the added advantage of saving on-the-job injuries.

When evaluating Sing galvanized metals for damages, a simple visual inspection will reveal whether or not the surface material has been compromised to the point of requiring maintenance.

The most cost-effective severe weather resistant material without compromise for strong hurricane proof* building material such as walls, roofs and/or floors for any emergent or disaster application perfect for battling hazardous weather conditions.

Sing 4×8 Galvanized wall panels are also used as roof panels, wall panels, trailer siding & roofing, billboards, kick plates, floor plates, curtain walls, movable house, display trestle, vehicle wagon, yacht interior & exterior, building exterior wall face-lifting, balcony, comportment, moveable metal storage shed and food truck walls.

Click here to see our weight evaluation of Sing metal table.

- Lightweight, easy to carry

- 20 ft. x 5 ft. x 1 in. Sing Sandwich

- Metal-Skin Sing Panel Exterior Sliding Door

- Lightweight metal roofing demo

*Customer will need to perform lab tests to certify hurricane rating for local code compliance.