Millworks are the premiere representatives of the ultimate expression of all that is SingCore.

It takes a village to bring a successful visionary project to life. It is the skills of the millwork are the main reason that Sing products look so amazing following installation in the field. Without the millworks who put the finishing touches on each Sing product, it would look like basic lumber, but after being finessed by highly skilled millworks, every Sing product is a beautiful, individual work of art.

SingCore is the secret ingredient in the process of bringing the best things to life.

How Sing Core Works With Millworks

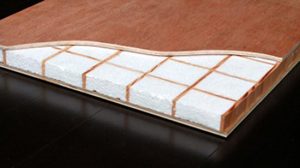

Sing Core supplies valuable components to the construction process. Patented Sing panels, posts and beams are integrated into projects where the characteristics of lightweight, high strength, insulation and alternative Eco-friendly manufacturing options are either sought after or used in solving the problems associated with large scale projects.

The process works something, like this:

- The Architect specifies, “SingCore” inside the products, let’s say, a large pivot door

- The General Contractor seeks out a qualified Millwork who obtains unfinished pivot door from Sing Core

- Sing Core manufactures the pivot door blank to architectural specs and ships to millwork

- Millwork finishes and installs hardware and provides finished pivot door to the job site

- Installers hang and or install the pivot door

The resulting large pivot door can be guaranteed not to warp, bend, twist or otherwise fail (including full structure warranty) for 50 years. No other door can offer such integrity, unless it has, “Sing Core inside.”

As SingCore is basically a patented unfinished building material with specific characteristics, millworks in particular provide all the talent, skills and tools necessary to transform basic SingCore into the exquisite works of art for which SingCore is so renowned.

As SingCore is basically a patented unfinished building material with specific characteristics, millworks in particular provide all the talent, skills and tools necessary to transform basic SingCore into the exquisite works of art for which SingCore is so renowned.

SingCore also serves other communities, like Architects and Contractors, when approached by anyone who does not represent a millwork, is it not uncommon for our staff to ask, “Who is doing he millwork on this project.”

Though SingCore is also available for retail via Lowe’s, this is only for the avid do-it-yourselfer or homeowner who has already secured a millwork facility to finish the raw SingCore material.

Why do millworks seek out SingCore?

Millworks are often approached to create products that are somewhat extraordinary and challenging. They are approached with a set of architectural drawings (in the best case scenarios) depicting the scope and vision of the architect, which can include challenges when translating the drawings and bringing them to life in the real world.

Key Characteristics

1 – Lightweight 2 – High Strength 3 – Warp-free 4 – Insulated

5 – 50 Year Guarantee

Millworks seek out SingCore to solve problems associated with oversize, large projects when size, weight and strength are key components of the project.

The #1 Solution for Large Doors

SingCore is the perfect answer for any large building project due to its unparalleled lightweight and strength. Large doors are especially problematic because they articulate and must seal properly to function as a door. As all door manufacturers and millworks know, all large doors warp.

SingCore is the perfect answer for any large building project due to its unparalleled lightweight and strength. Large doors are especially problematic because they articulate and must seal properly to function as a door. As all door manufacturers and millworks know, all large doors warp.

This is a problem because the millwork (or door company) wants to guarantee their work, and often will offer a warranty on everything – except – the large door, because it is acknowledged in advance they will warp, and the customer will have to waive rights to a warranty on the large doors and be liable for maintenance costs due to their insistence of incorporating big doors in the project.

50 Year Warp-free Guarantee

SingCore works hand-in-hand with millworks to bring the architectural visions to life, without fail. Our true flat specialists can help to design a large warp-free door of any style, shape and size, made of any material, like any available wood species, aluminum, concrete, fiberglass (FRP), HPL, Kevlar, LVL, steel, etc… and can be guaranteed not to warp, bend, twist, cup or otherwise fail (including full structure guarantee) for 50 years. No other company can guarantee a large door, like that, unless it has SingCore inside.

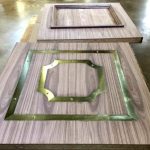

Custom Interior Blocking

Your custom Sing panels can feature solid wood (or other specified material) edges or interior blocking for internal connection or hard points. Other customizations available at time of manufacture include custom blocking and lite cutouts for glass or window installation post production.

Your custom Sing panels can feature solid wood (or other specified material) edges or interior blocking for internal connection or hard points. Other customizations available at time of manufacture include custom blocking and lite cutouts for glass or window installation post production.

As far as edge banding is concerned: Sing Core and Sing panels are easily edge-banded the same as any standard solid wood. It does not require any special, expensive edge-banding machine like paper honeycomb or other types of honeycomb panels.

Millwork-ready Versatility

SingCore products are a perfect match for millworks because they already have all the necessary skills, tools and equipment to see that SingCore strengths shine through in the best way(s) possible. While SingCore is well known for building the best, large lightweight structurally sound products, it is the skills of the millworks that make the end product and us look so outstanding following project completion.

Sing products can be easily worked with standard woodworking equipment, can be ripped, sawed, drilled and CNC routered just like any other piece of plywood.

Any Surface Material Available

Sing panels can be custom-manufactured to meet your specifications and can host any available flat building material. Some millworks prefer to order SingCore base material with lightweight plywood skins then apply other surface materials in their shop, while others prefer SingCore to deliver the product with the custom surface material adhered at our factory.

When gluing surface material over Sing panels and Sing beams, Sing panel works as the substrate. You could use hot press or cold process to adhere veneer and/or HPL. We can apply any external surface material that you require. The best glue for the best bonding of Sing panels includes PVA or urethane glue.

Bulk Runs

Bulk Runs

When a millwork (or door manufacturer) is faced with a large number of oversized doors (like an order we processed recently for 700 10 ft tall doors for a client in the Midwest) SingCore can quickly manufacture and deliver the unfinished door blanks to the millwork for finishing saving time and money, besides delivering a wildly superior product increasing customer confidence/satisfaction and the bottom line.

Our team helps your team win the bid by assisting in engineering (or re-engineering) the products required to meet both budget and performance requirements for large doors and large orders.

What is Sing Core?

The best way to learn is take a glance of the charts to see the comparison of the most popular core materials available in today’s market place. SingCore’s torsion box composite structure stands out from the rest of commercially available core materials, it has a very good track record of its performance, above and beyond the impressive comparisons shown in the charts.

| Sing Core | Wood-based | Foam | Aluminum | Balsawood | Nomex | Plastic | Cardboard | |

| Insulation | ✓ | ✓ | x | x | x | x | x | |

| Sound Deadening | ✓ | ✓ | x | x | x | x | x | |

| Lightweight | ✓ | ✓ | ✓ | ✓ | ✓ | x | x | |

| Strength | ✓ | x | ✓ | ✓ | ✓ | x | x | |

| Solid | ✓ | ✓ | x | ✓ | x | x | x | |

| Eco-friendly | ✓ | x | x | ✓ | x | x | ✓ | |

| Renewable | ✓ | x | x | ✓ | x | x | ✓ | |

| Oversize | ✓ | x | x | x | x | x | x | |

| Dimensionally Stable | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Affordable | ✓ | x | x | x | x | x | ✓ | |

| Waterproof Upgrade? | ✓ | ✓ | ✓ | x | ✓ | ✓ | x | |

| Fire Retardant Upgrade? | ✓ | ✓ | ✓ | ✓ | ✓ | x | ✓ | |

| Bullet-proof Upgrade | ✓ | ✓ | x | x | x | x | x | |

| Thickness Available | ✓ | x | x | x | x | x | x | |

| Skin Options | ✓ | x | x | x | x | x | x | |

| Easy to Machine | ✓ | x | x | x | x | x | x | |

| Fast Turnaround | ✓ | x | x | x | x | x | x |

Sing Core Durability.

Products made of Sing panels are easy to repair damage to its original condition simply and easily by cutting a hole (you can even use a chain saw due to its unique Sing Core structure and stress skin). If you cut a hole in a solid wood panel, does not have stress skin to enforce the structure; the same with any other type of core, they just cannot adequately survive the procedure because they lack significant core structure strength. Any repairs will have the strength, integrity and durability of the original structure.

See: Door Specifications

- Cedar wood stave