Large sliding barn doors are an important feature in the biggest warehouses and industrial locations in the United States, from military to aerospace a big sliding barn door is often specified in the architectural designs for practicality and ease of use. But the larger the door opening the harder it is to keep these huge sliders from warping. If you cannot keep the door straight, you may have reduced access due to door failure.

Ceiling mounted barn doors 14 ft. x 3.5 ft. x 2.5 in.

For years, inventor Peter Sing’s patented warp-free sliding barn door solutions have been the answer to these massive sliding barn doors, which using his patented and patent-pending anti-warp solutions can be built lightweight, high strength, and be guaranteed not to warp for 50 years, unheard of before the invention of Sing Core.

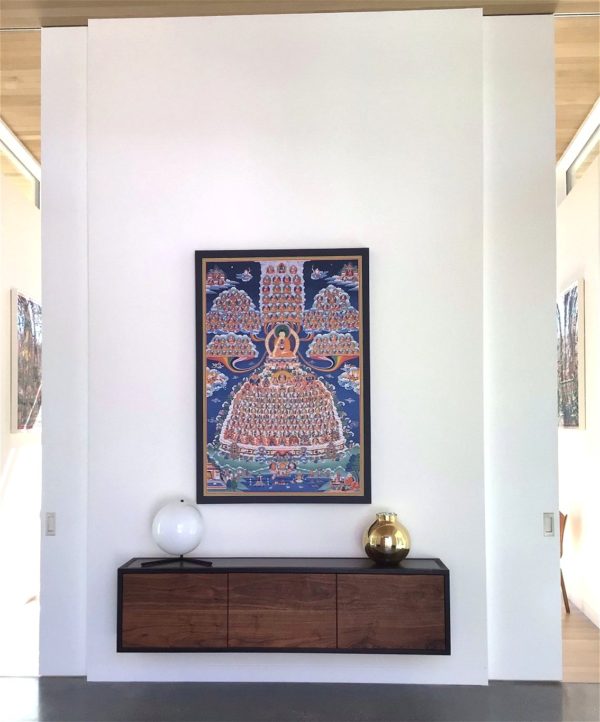

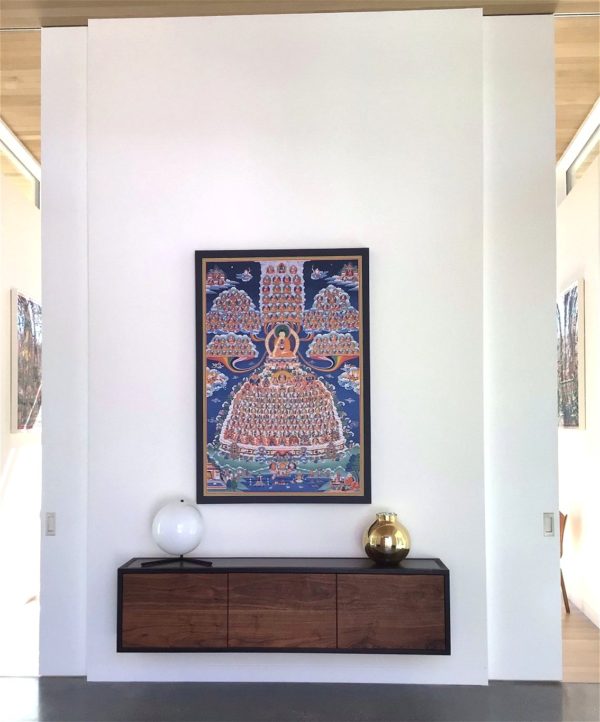

Ceiling mounted barn doors closed

Entryway door

If you would like to see the story behind the doors pictured above, click here or either photo.

Interior Barn Doors

As interior design has evolved, the integration of interior modern barn doors in everything from residential to commercial projects has seen rapid growth. Of course, standard-sized interior sliding barn doors do not pose much of a challenge, but if the door exceeds 8 feet tall or a 4-foot width, now you are heading into dangerous territory if you are hoping for a non-warping sliding barn door.

Warped Large Sliding Barn Doors

Regardless of the application, large sliding barn doors are going to be problematic, so much so that years ago, the biggest door companies in the USA excluded offering the large barn door from their door schedules, instructing contractors to seek out custom door makers or millworks, because they could not cover these enormous sliding barn doors with any warranty because they were destined to warp and fail not long after installation.

After a while, even the millworks started turning down jobs for large sliding barn doors for the same reason, too many service calls during the warranty period, though this did open a door for door service companies whose job it was to regularly maintain doors, though this was extremely expensive for end user of the warping big sliding barn door.

Not Faulty Design

The problem, it turns out was not with the design, as large sliding barn doors were both stylish and practical, so the architects could not be blamed. The problem is with the limitation in building materials. A dimensionally stable door could be made of a thick solid material such as solid steel, but the bigger the door gets, even solid steel will move according to changes in the environment. Sing is able to bring the ideas of the architects and designers to life in such as way as to provide a 50-year solution to such visionary ideas.

Warp-free Solution

When inventor Peter Sing introduced his warp-free technologies to the large sliding door companies, they embraced Sing’s solutions for warped large sliding doors. Thanks to Sing, they were able to get back into the oversized door market once again. According to them, in their own words. Sing’s core,

“Is the only way to build a lightweight warp-free large door.”

The only way.

A Door is Not a Wall

It is important to learn what the core structure is made of. Doors are not the same as walls. Doors need to move repeatedly everyday while walls are permanently placed. Walls commonly use 2” x 4” framing methods which do not work well for building doors. If the structure of the door is not strong, it will not feel or sound very solid. When you close the door, there will be rattling sounds and/or it can deform over time. It is very easy to tell, all you have to do is close the door and hear how strong or solid the door is made. It may look the same, but it does not sound the same. You can tell the difference by knockings on the door, you can tell what is inside. Solid like a rick but still light like a feather when you swing the door closed. The structure of the door that makes the difference, not the door skin.

You Want a Warp-free Large Sliding Barn Door

We already know you want a large warp-free sliding barn door. How do we know? Because Sing’s email servers are filled with people asking about how they can get a sliding barn door with Sing Core inside? Unfortunately,

Sing Core Does Not Sell Doors

Even though sliding barn doors with Sing’s core inside are among the best doors in the world, Sing’s factory does not build doors. Rather, they provide the raw warp-free base materials to the door building companies and millworks who create the enormous warp-free sliding barn doors, that the inventor is credited with, even though Sing only provides the base material. So, if you really want one, just contact your favorite door builder or millwork and tell them you want a door, “with Sing Core inside.”

What is the Secret?

How to Build a Large Sliding Door

Undoubtedly, you have wondered how does Peter Sing build such large lightweight sliding barn doors that are stronger than steel pound for pound and can be guaranteed not to warp for 50 years? Following are the methods that Sing uses to build warp-free doors of any size, made of nearly any flat building material, secrets revealed.

First, the architect or door engineers, specify the door dimensions and the material that the door will be made of, and submit the specs to Sing’s True Flat Team. The team goes to work, gathering all the data necessary to predict what the challenges will be for the door. Questions like, will it be an interior or exterior door? Will it be exposed to the elements? In what geographical location will the door be installed and at what altitude? Which direction will the door face?

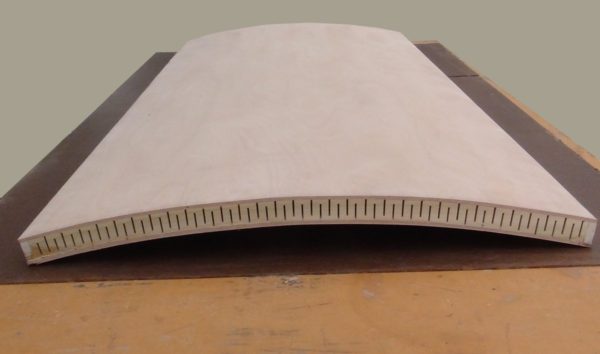

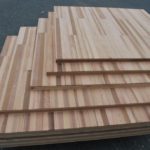

The team starts with Sing’s patented rigid foam reinforced torsion box core, then add additional patent-pending anti-warp technologies to compensate for exterior door skins and environmental concerns.

That is the secret inside these huge warp-free doors.

How Can You Ship Such Large Doors?

Of course, the military can do amazing things with transportation that cannot be accomplished by mere mortals, so Sing has created a modular technology that supports his 50-year guarantee. In this manner, any size of door can be built and shipped in high precision sections that are assembled on-site.

Joining a modular door shipped in sections

This saves so much on shipping and handling costs, and if the large door needs to fit in an elevator or tight doorway, not problem. High precision modular solutions are the answer. Sing Core has built many large doors that are joined on-site without any warping.

Don’t try this at home. Average dowels and even larger biscuit-joining will not prevent door warping. Let’s say you wanted to build a pair of 10’ x 20’ double barn doors that were 2-inches thick. Stacking and joining four 5’ x 10’ x 2” panels together will not be an easy task. But Sing Core has had many years of experience with oversized doors, and has been devoted to solving the common issues with larger modular doors.

If you have a good budget, high precision demand, and no issue accessing the job site then a one-piece large door panel is the way to go, if it can be shipped to your location.

Otherwise, modular door sections joined on-site will be the best option. There are two major factors to achieve high quality when building large doors. One is to make sure there is no warping once the modular sections have been joined. The second issue is maintaining a high precision joint line so that it is not noticeable. This requires a very high precision core to achieve. Sing Core is the most precision door core available, with a tolerance of ± 0.007”. It is important to be sure that the thickness of the core is within these tolerances.

Elegant Mahogany sliding door

Weight and Strength

Strength plays a key factor when building larger doors. Traditional door building methods may dictate that strong doors are heavy and lightweight doors are weak. Weight is a major issue with oversized doors. Heavy doors are significantly more expensive due to additional structure costs, higher labor costs, and extra shipping and handling costs. Heavy door core does not mean that it will have high strength and the larger the door is, the more strength is necessary to maintain a long lifespan.

What type of skin is best to build a large modular door?

Paint Grade – It is easy to hide the seams. Seams can be almost unnoticeable if modular sections are joined with a Sing Spline. If the spline is made of solid wood, it can move or warp after the moisture levels change and it will be reflected on the surface of the door. This can cause the surface of the door to crack after the seasons change.

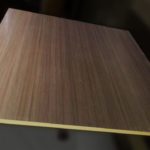

HPL (High Pressure Laminate) – See how precise the joint is using only a Sing Spline. HPL is available in a wide variety of patterns. The best choice for HPL is a vertical pattern to help the joint blend into the surface. HPL is a good choice when ordering one of our modular oversized doors. The patterned HPL allows the joint line to be hidden in plain sight. The door can be as big as 12 feet tall and 40 feet wide without having any noticeable seams.

Metal

Metal – If it is paint grade metal, the seam can be filled with joint compound and then painted making a seamless joint. Metal doors are traditionally very heavy, but with Sing Core inside your metal door can weight roughly 1/3 of a traditional metal door. You can choose from any type of metal you would like, but our most commonly made metal doors are Aluminum or Cold-Rolled Steel. Click here to see a

paint grade Sing metal door.

FRP – FRP, or Fiber-Reinforced Plastic, can be used to make very large doors and very durable doors. FRP can be smooth or have a textured surface. It is much more visually appealing and functions much better than solid wood which has potential to crack, warp, twist, and cup. Besides, solid wood weights a lot more than Sing wood stave planks. Sing wood stave planks are the ideal material to replace solid wood for such jobs as, doors, tabletops, post and beams, and many more. An advantage of choosing wood staves are that they are much more precise than solid wood because their tendency to move over time is minimal in comparison. On the other hand, wood staves are much harder to match with surrounding patterns than a wood veneer skin.

Wood Veneer – Wood veneer has an average thickness of 0.020″-0.030″ and is very difficult to hide joint line in the face of the panel. Wood veneer is often much more challenging because it is usually very thin, normally only 0.020” thick. We always suggest using thicker wood staves which are usually 0.125” thick rather than veneer. However, Sing Core has a proprietary technology to make a veneer panel seamless as large as 10′ by 16′. This requires the veneer to be staggered and hot-pressed. It is very costly to use veneer, oftentimes we use wood staves to build larger doors.

For a tighter budget, we recommend using a paper backed veneer which only requires being cold-pressed. Sing Core provides the smoothest MDF skin for our clients to hot-press. Cross banding is not required with our smooth and high precision substrate, which may be hard to believe for some people. We have been doing this for many years with our innovative technology. We always recommend that our clients purchase our veneer substrate, complete with the same warp-free guarantee, and hire your local veneer contractor or do it yourself to save some money. One advantage to using a wood veneer as the skin for your door panel is that veneer can be easily matched to the surrounding area. One disadvantage to using wood veneer skin is that it is not well suited for exterior purposes, such as entrance door, and it can be difficult to repair if damaged. Veneer skins are the also limited to the maximum door size of 10′ by 16′.

Gallery

SingCore specializes in producing the highest quality sliding garage doors on the market. Our patented and patent pending core material is ultra-light weight yet super strong. Choose any style of door, skin material, or hardware arrangement that you desire. We building custom door panels to match your specs exactly.

SingCore specializes in producing the highest quality sliding garage doors on the market. Our patented and patent pending core material is ultra-light weight yet super strong. Choose any style of door, skin material, or hardware arrangement that you desire. We building custom door panels to match your specs exactly.

In the new decade, large over-size sliding doors are landing large amount architects and design professionals all over the United States. Whether a man door type for convertible office spaces or a movable wall design for that open concept in to private meeting space ascetic, large sliding doors are set to be the hallmark of the coming decade of design. Architects, millworks, interior designers, and high end contractors all best be aware of this coming trend.

In the new decade, large over-size sliding doors are landing large amount architects and design professionals all over the United States. Whether a man door type for convertible office spaces or a movable wall design for that open concept in to private meeting space ascetic, large sliding doors are set to be the hallmark of the coming decade of design. Architects, millworks, interior designers, and high end contractors all best be aware of this coming trend.