If you’re a millwork who answers the call of exclusive and demanding clientele seeking large doors or a high end custom door manufacturer, you’ve already sought out information on how to build a torsion box door because the only large doors with some degree of stability and are not extremely heavy are torsion box doors.

You may have already had the experience of going through the painstaking arduous process of building your own torsion box core to form the basis of your custom large door. For those who may be asking, “What is a torsion box door?” It requires creating a grid of boxes side-by-side. These boxes help to create a push-pull interior structure for the torsion box door which can feature exterior materials (or skins) of wood (or some other flat building material) that counteracts the natural characteristic of organic woods to warp, bend and twist. While this is a very labor intensive and expensive process, it does help to create a lightweight structure with the ability to have less deflection over a long span. Besides torsion box doors, you also see torsion box solutions for large torsion box tables and dead flat torsion box work surfaces.

As you might imagine this is a time consuming rigorous task, especially if you’re considering small torsion boxes within your torsion box door, which is many times more difficult. The smaller the torsion box grid size, the greater the strength and warp resistance of the resulting torsion box door. The most common torsion box grid sizes are four to six inches.

Fortunately, SingCore offers a superior torsion box door core material that is many times more effective than building a torsion box door core yourself, pre-insulated and structure-enhanced and pre-manufactured at an affordable price.

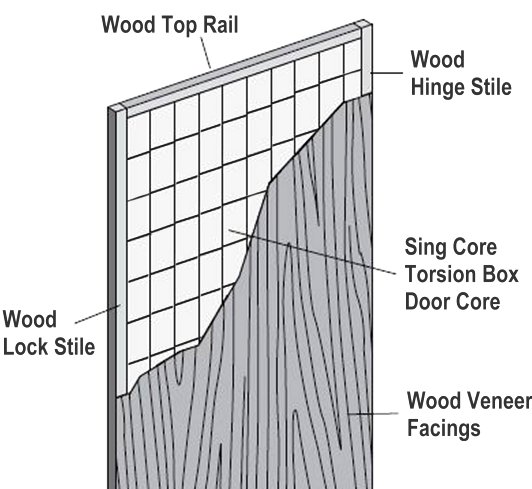

Anatomy of a Sing Torsion Box Door

First of all, SingCore pre-manufactured torsion box door core starts with small torsion box structure grids in three sizes: 3×3 inch, 2×3 inch and 2×2 inch torsion box grid sizes. These small torsion boxes provide a high degree of stability, but that’s not all there is to the patented SingCore torsion box.

To increase the strength of the torsion box structure, inventor Peter Sing flips the wood grain in his torsion box core material. While most woodworkers use horizontal grain wood to build their torsion boxes, Mr. Sing uses vertical grain wood which increases the strength of the torsion boxes themselves many times over. But he doesn’t stop there.

To increase the strength of the torsion box structure, inventor Peter Sing flips the wood grain in his torsion box core material. While most woodworkers use horizontal grain wood to build their torsion boxes, Mr. Sing uses vertical grain wood which increases the strength of the torsion boxes themselves many times over. But he doesn’t stop there.

His patented torsion box design also packs the voids of the torsion boxes (that would normally be left empty) with rigid recycled foam wall-to-wall, which when glued and pressed between stress skins results in a solid sandwich panel with unparalleled insulated structure and shear strength, while remaining very lightweight.

Now that you know, you could go ahead and build your own super duper torsion box door, or you could let SingCore do all the heavy lifting for you because that’s all we do.

At SingCore, all we do is build the best torsion box core for the best torsion box doors in our factory located in the pristine Pacific Northwest. We use local labor in our factory to build high precision core (+/- .006 in.) to supply the best millworks and door companies in the world with our patented torsion box door core material. Though we do not actually build or finish the doors ourselves, we do provide the best lightweight, high strength (660 PSI) torsion box door core to the professionals who make the most elegant finished doors that can be guaranteed not to warp, bend, twist or otherwise fail for a full 50 years because they have patented SingCore inside.