Please Note: Standard lead times are 6-10 weeks. Rush orders are available if required. No “Will Call” pick-up orders.

You will automatically receive SingCore promotional emails.

Opt out at any time. SingCore will never sell your information.

RUSHED PRODUCTION SCHEDULE

Every order SingCore manufactures is custom made, so please bear that in mind in regards to your project’s timelines. If you require a rush order, rush fees are as follows:

- Ship in 4 weeks – 20% price increase

- Ship in 3 weeks – 40% price increase

- Ship in 2 weeks – 70% price increase

- Ship in 1 Week – 100% price increase

SING CORE GRADES

Sing products are available in your choice of three formats to accommodate your specifications and expectations:

- Standard: The strongest, lightweight Eco-friendly building material invented

- Professional: Specially formatted for non-warp performance, guarantee for 50 years

- Hot Press Ready: Hot-press-ready (for thin veneer)

SING CORE GRID SIZE

Our grids come in small, medium and large sizes.

INSULATION VALUE

- R-value 3.5 (EPS foam)

- R-value 5.7 (urethane foam)

SOLID WOOD EDGE AND LOCK BLOCKS

SKIN CHOICE (SURFACE MATERIAL)

There are many options for Sing Core panels. (See: Material Options)

- Paint Grade: 1/4 inch or thicker plywood, mdf, Masonite

- Metal: .20 inch to .125 inch aluminum, cold rolled steel, galvanized steel, hot rolled steel

- Wood Grain: Thin wood veneer .020 inch on top of .125 inch mdf over top of aluminum Sing panel

- Wood Stave: .125 inch applied over the top of aluminum the Sing panel substrate or on top of the .125 inch mdf over the top fo the aluminum Sing panel

- FRP Fiberglass

- Galvanized steel

- Aluminum

- HPL Formica

- Masonite

- Cold Rolled Steel

- Hot Rolled Steel

- Magnesium board

- Marine grade plywood

- MDF

- Metal

- Plastic

- Stainless steel

- Fiberglass

- Concrete

- Ceramic

WINDOW AND DOOR CUTOFFS

Sing Core provides Sing panels with window and door pre-cut and ready for installation. We will cut 1/8 larger in width and 3/16 inch wider in length to fit your window glass. We build a frame using 1.25 inch solid wood to your specifications.

MOLDING/TRIM

Sing Core windows and doors are profile ready for CNC routing. You may add molding or trim to create your own window or door design, otherwise we will provide you with thicker skin – such as 1/4 inch or thicker mdf, hardboard, etc. – for you to carve or profile by CNC machine. With Sing Core windows and doors you can create a true raised-panel door or any design you desire.

TRIMMED OR UNTRIMMED (RAW EDGES)

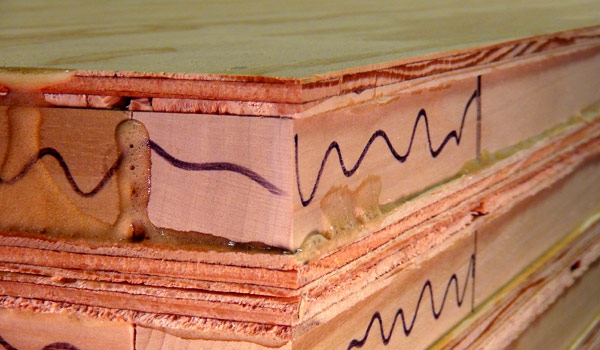

The standard ready-to-ship panel condition is, “untrimmed.” This leaves unfinished exterior edges that may have exposed adhesive and might require being built ½ inch over-sized for trimming at your location. An additional fee will be assessed for trimming and sizing in our factory.

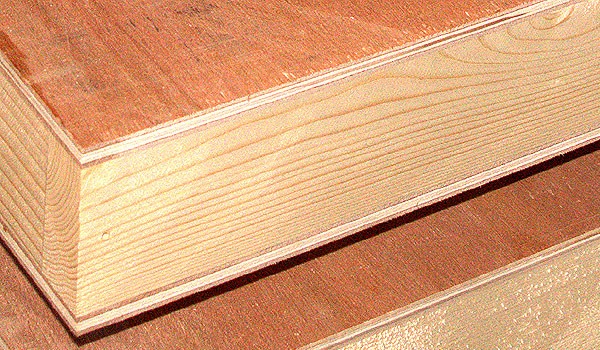

All trimmed edges are 1/2 inch over width and 1/2 inch over length. After trimming, your Sing Panel will be 1/2 inch less (4 x 8 will be 47.5 inch x 95.5 inch). Standard solid wood edging with 1.5 inch will be reduced to 1.25 inch after trimming.

UNTRIMMED PANEL (RAW)

Many of our customers prefer their panels untrimmed because this allows them to trim their panels to exact size on site before installing them in their door openings. That way they can have the peace of mind that their door will fit the opening exactly as intended.

TRIMMED PANEL

Customers who want their panels cut to exact size before they receive them should choose the trimmed selection. This gives them the option of doing less work on site, but it also means they must be much more precise with their measurements before ordering their panels. Trimmed also costs slightly more because it is more labor intensive to trim the panels in house.

SING PANELS FEATURES

SING CORE PRECISION

WEIGHT

COMPRESSION STRENGTH

SING PANEL INSULATION

SOUND-DEADENING

BULLETPROOF RADIATION-PROOF DOORS

WARRANTY

Sing Products come with a limited lifetime guarantee. (See http://singcore.com/education/warranty)

OUR 50-YEAR NON-WARP GUARANTEE

SING CORE TERMS

All orders are subject to Sing Core’s Terms of Service.